iPAK2 User Guide

60

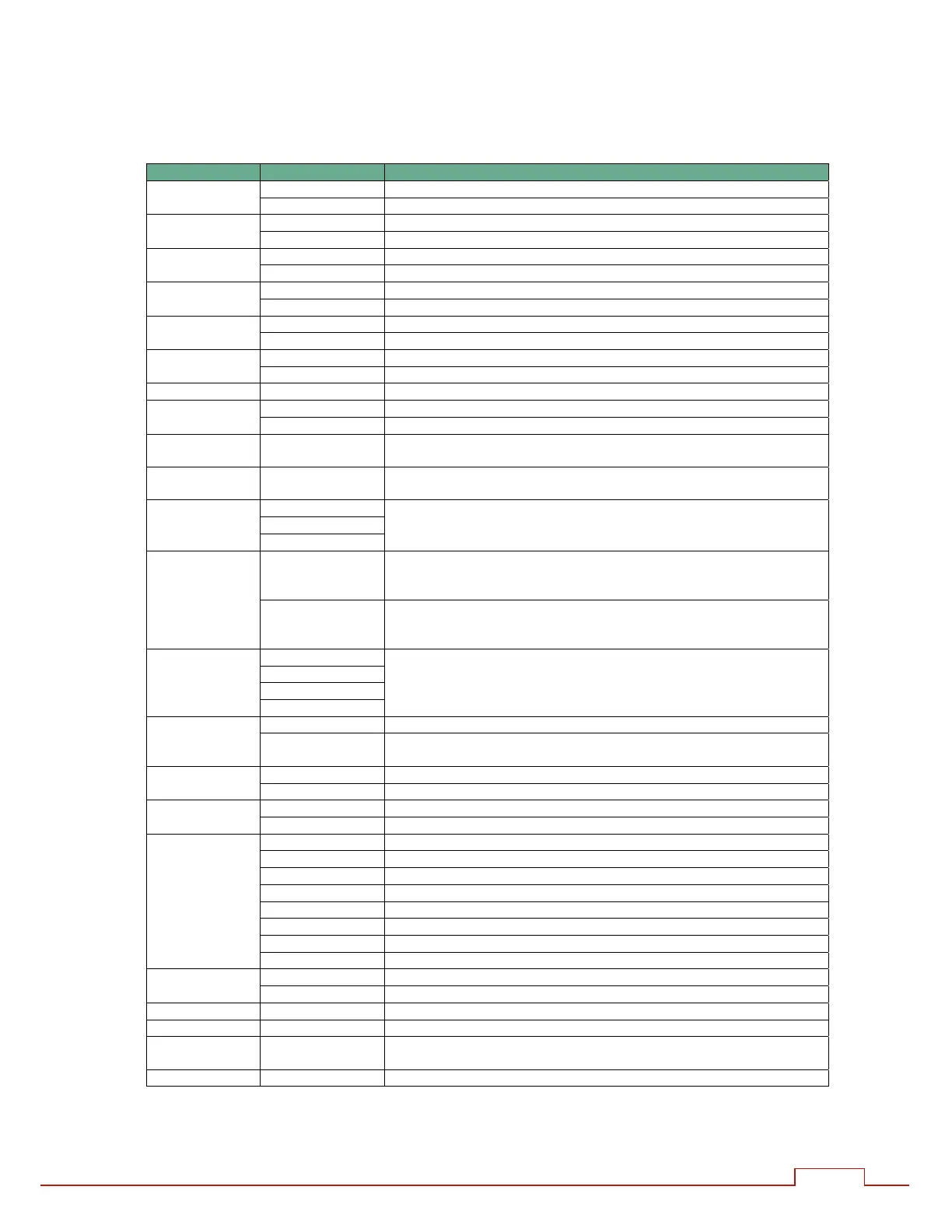

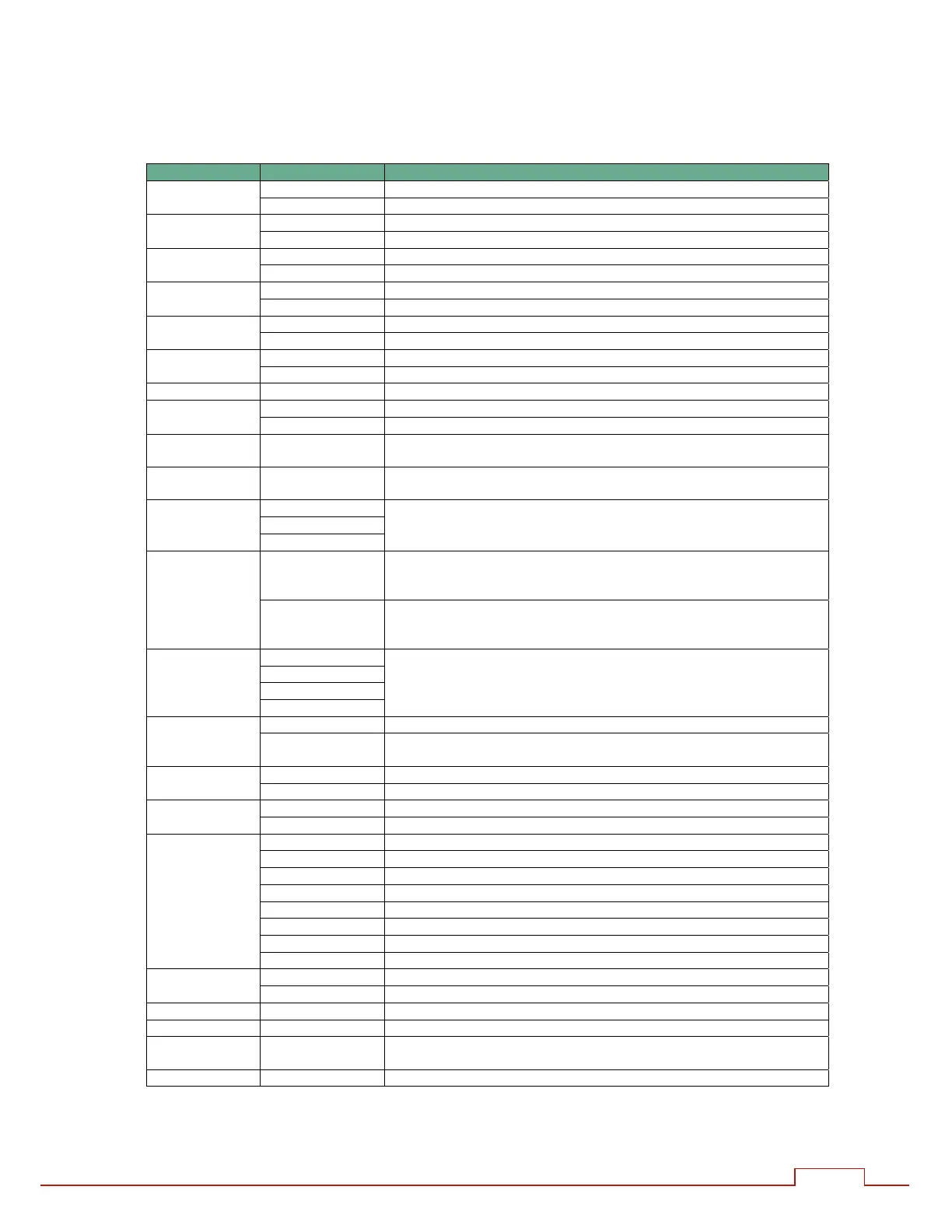

8. Configuration

1

iPAK2 only.

2

iPAK2 fitted with EtherNet/IP adapter, or iPAK2v2.

Parameter Value Description

Features

Standard Selects standard features.

Extended Selects extended features.

Weld type

Spot Selects spot welding features.

Seam Selects seam welding features.

Measure

Primary Measure primary welding current

Secondary Measure secondary welding current

Regulation

Primary Regulate primary welding current

Secondary Regulate secondary welding current

Units

Metric Force in KN.

Imperial Force in lbf.

Program select

External The Program Select inputs select the weld program.

Internal The Use Program parameter selects the weld program.

Use program 0 - 255 The weld program that will be used if Internal program select is set

Electrodes

Single Use one electrode for the weld programs.

Multi Use up to 8 electrodes for the weld programs.

iPAK(v1) mode

Yes/No Changes the sense of the READY output to NOT READY.

AV4, 5 and 6 are used for MUX selection.

Ip limit

0 – inverter

specific

Sets an upper limit on the inverter output current

3

2

nd

stage

Off Selects the second stage function. See Welding control – timing

diagrams section.

Before Squeeze

After Squeeze

2

nd

stage

Once The 2

nd

stage input is checked only at the start of the first spot in a

sequence. Applies to spot-repeat, cascade and roll-spot modes

but not seam.

Every The 2

nd

stage input is checked at the start of every spot within a

sequence. Applies to spot-repeat, cascade and roll-spot modes

but not seam.

Retract

Simple Selects the Retract function. See Welding control – timing diagrams

section.

Hilift +

Hilift -

Maintained

Stop on fault

No In the event of a fault further welds will be permitted.

Yes In the event of a fault, a fault reset is required before further welds

will be permitted.

EOS on fault

No In the event of a fault the EOS output will not be activated.

Yes In the event of a fault the EOS output will be activated.

Headlock on

fault

No In the event of a fault the welding head will not be locked.

Yes In the event of a fault the welding head will be locked.

I/O source

Discrete Use the discrete inputs and outputs.

COM0 Use MODBUS TCP/IP (Ethernet) on COM0

1

COM1 Use MODBUS TCP/IP (Ethernet) on COM1

1

COM2 Use MODBUS RTU (RS485) on COM2

COM3 Use RS232 on COM3

COM4 Use MODBUS TCP/IP (Ethernet) on COM4

2

COM5 Use MODBUS TCP/IP (Ethernet) on COM5

2

COM6 Use EtherNet/IP on COM6

2

Analog output

Force The analog output is used to control force.

Current The analog output corresponds to the measured weld current.

Waveform 10V = 0 – 500kA Sets the analog output scaling for the measured current option.

Contactor 0 – 99 seconds The contactor output is sustained for this time following a weld

Toroid test

Off / On The connection to an external toroid will be tested. The measured

resistance must lie within the range 10 to 300 Ohms.

Analog control Off / On The heat or current can be controlled via the analog input.

Loading...

Loading...