Maintenance 1. Safety Precautions on Maintenance

CAUTION

Do not lose the screws removed at maintenance. When the screw is dropped

into the Controller, be sure to take it out.

Leaving the screw in the Controller

may cause short circuit and may result in equipment damage to the parts and/or

robot system.

power rating (wattage) of a new Motor Driver module is

Using a Motor Driver module with improper power rating (wattage) in

Controller may cause improper function of the robot system and errors.

The serial number of the Manipulator that should be connected is indicated on

the

Connection Check Label on the Controller. Connect the Controller and the

Improper connection between the Controller and the

Manipulator may cause not only improper function of the robot system but also

serious safety problems.

Before performing maintenance on the Controller, all the data must be copied as a backup.

The details of data backup/restore are described in the Maintenance 4. Backup and

Restore.

1.2 Lockout / Tagout

Lockout / tagout is a method to prevent any one from turning ON the robot system by

mistake while someone else is within the safeguarded area for maintenance or repair.

When performing maintenance and repair, lockout and tagout using the following

procedure. Use the lockout attachment for RC90.

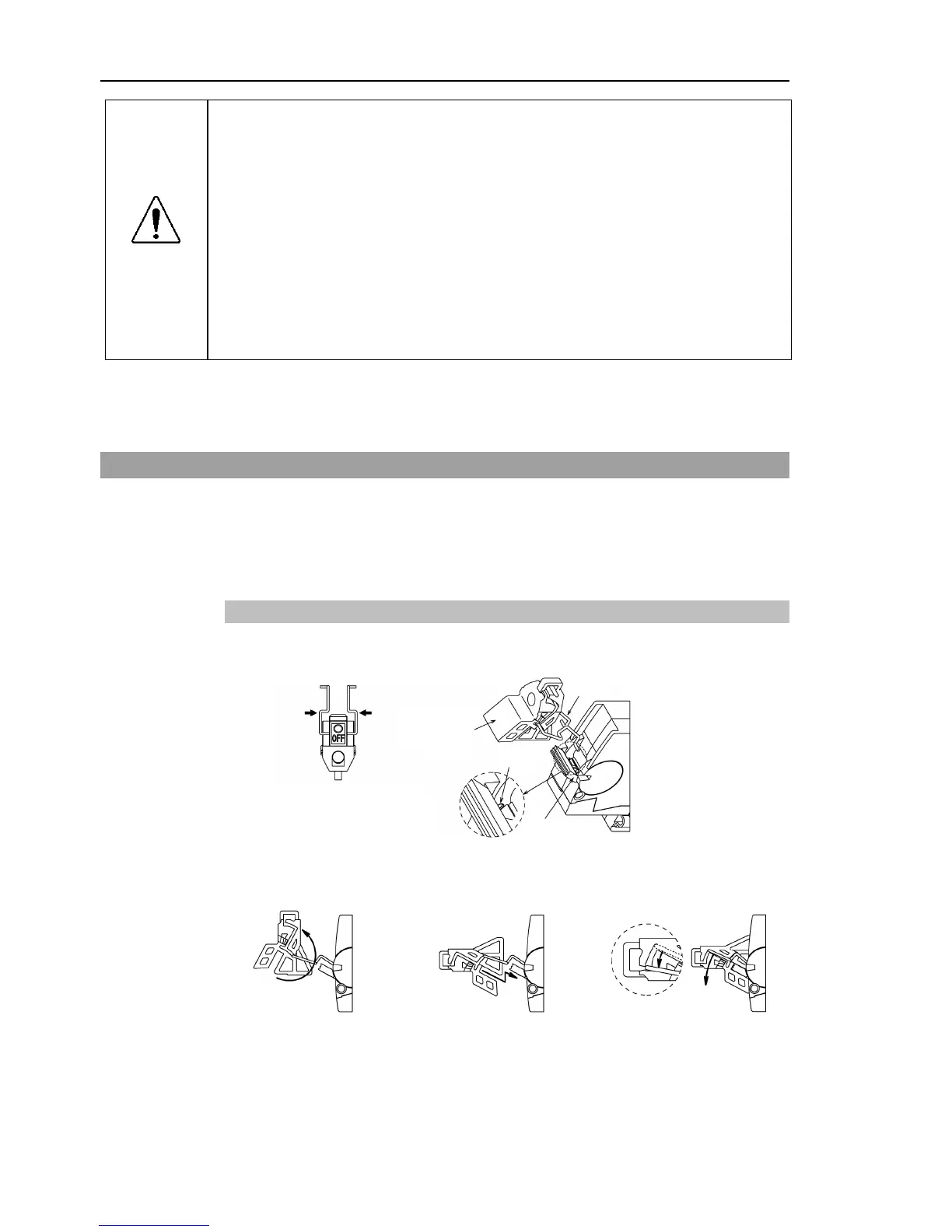

Installing the Lockout Attachment

(1) Turn OFF the POWER switch and place the lockout attachment on the POWER switch.

Insert the pin in the holes under the retractable actuator.

Push the pin in the direction

of arrows,

and insert the pin

in the holes.

(3) Install the lockout

attachment on the

82 RC90 (EPSON RC+ 7.0) Rev.4

Loading...

Loading...