LUBRICATION AND MAINTENANCE

5-12

Every 40 Hours

The following services must be performed after every 40 hours of operation of the Apache Sprayer.

Torque Lug Nuts

Torque the 12.4” x 28” front wheel lug nuts to

180 lb-ft [244 N•m].

Torque the 14.9” x 38” front wheel lug nuts to

315 lb-ft [427 N•m].

Torque all rear wheel lug nuts to 460 lb-ft

[624 N•m].

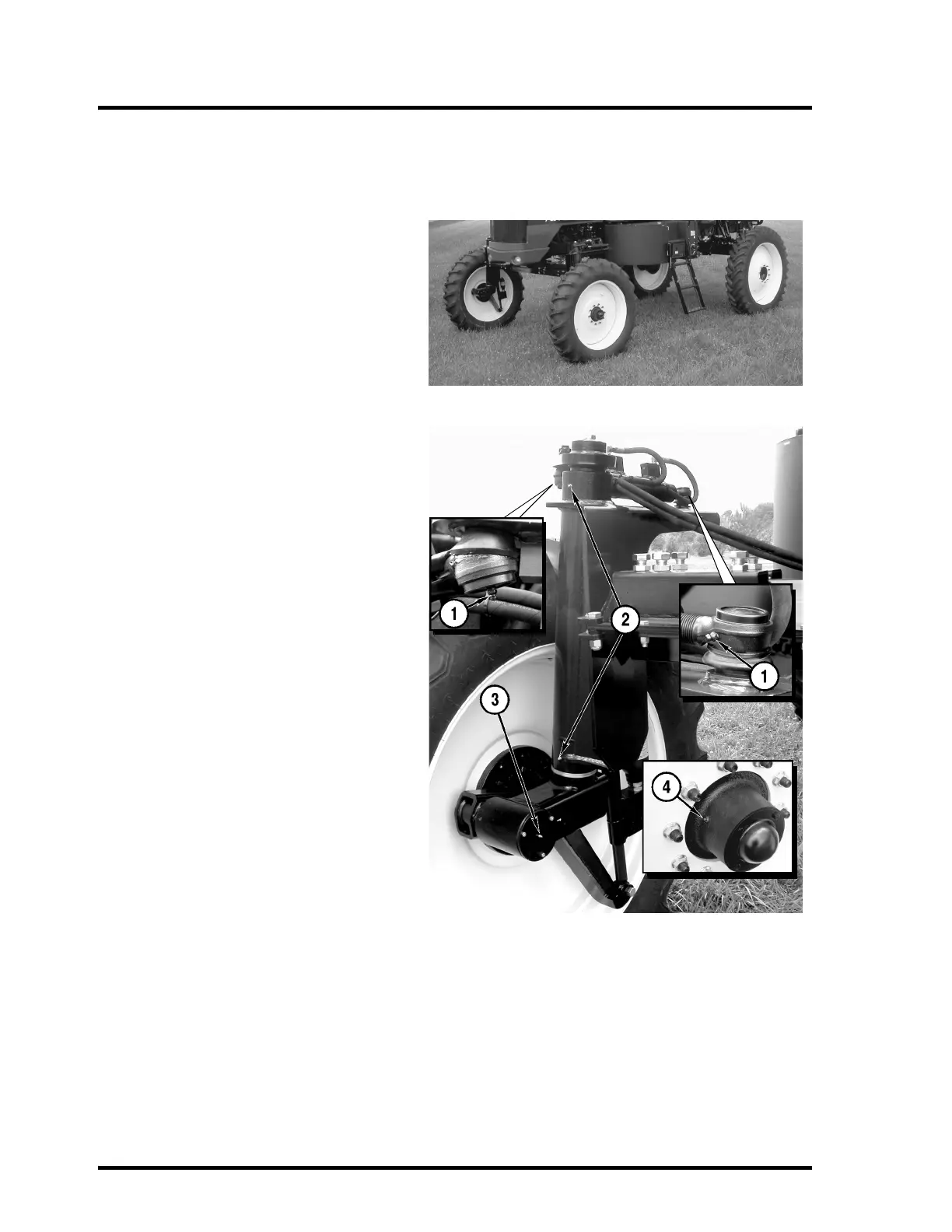

Grease Steering Components

IMPORTANT: Do not over-grease the ball-

joints. Damage to the dust cover will result.

Each steering cylinder has two ball joint

grease fittings (1), two king-pin grease fittings

(2), one inter-flex bearing grease fitting (3),

and one hub grease fitting (4). The right

wheel is shown.

Apply lithium grease through the two ball-joint

grease fittings (1) on the tie rod ends.

Apply lithium grease through the two king-pin

grease fittings (2).

NOTE: The inter-flex (3) and hub (4) bearings

are sealed chambers and once greased

require very little grease to maintain.

Apply lithium grease through the inter-flex

bearing grease fitting (3).

Apply lithium grease through the hub bearing

grease fitting (4).

Repeat these steps for the other front wheel.

Loading...

Loading...