Corrective Maintenance

Fox Maintenance © Essemtec AG 5-9

0000074/05

/ March 31,

2017

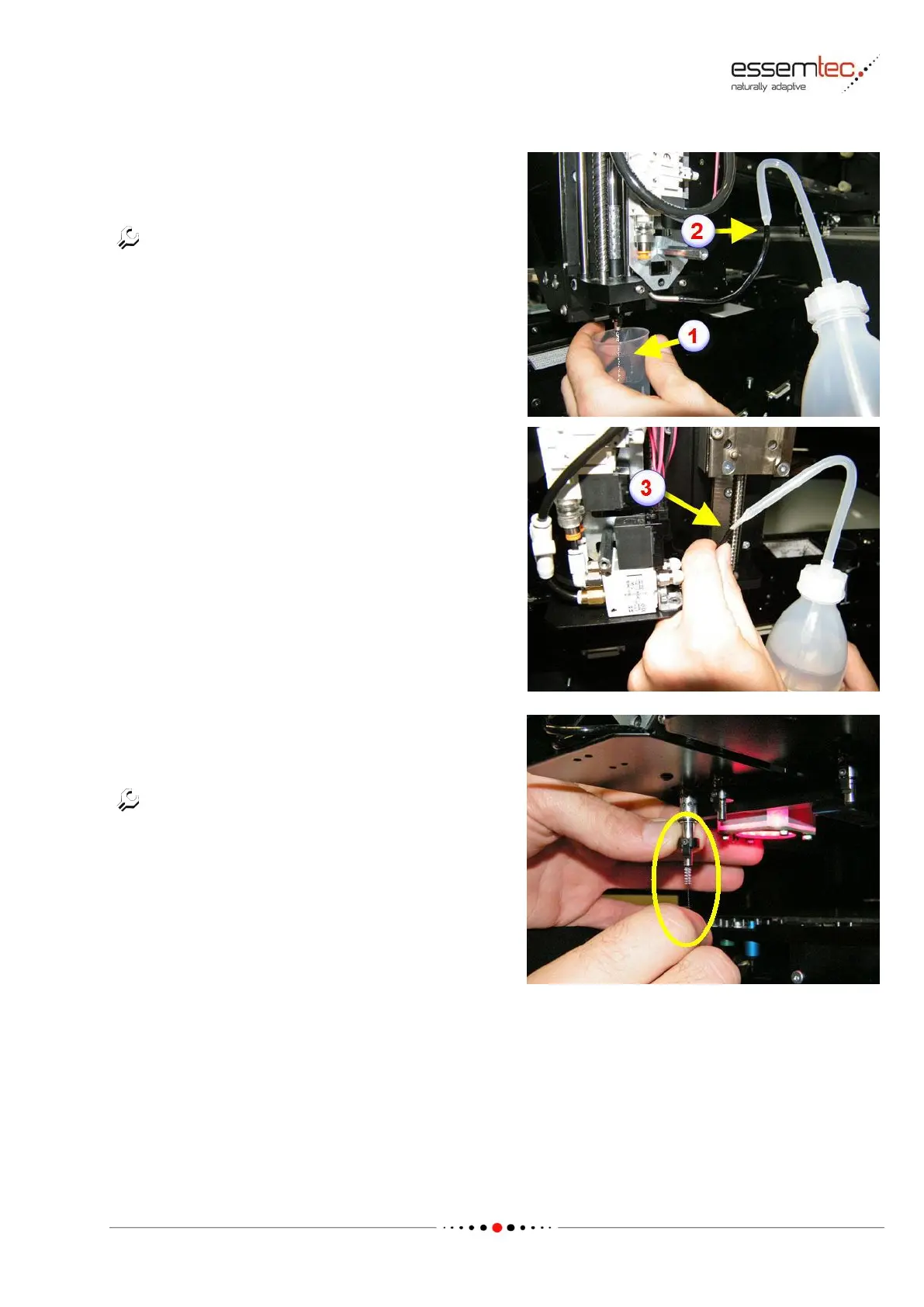

Position the reject bin underneath the ZT

elements for the collection of the rinsing liquid

(1).

By means of the squeeze bottle, syringe or

similar dosing unit, press the Isopropanol or

methylated spirit through the first passage to

rinse it (2). Vacuum passage with blow off (3).

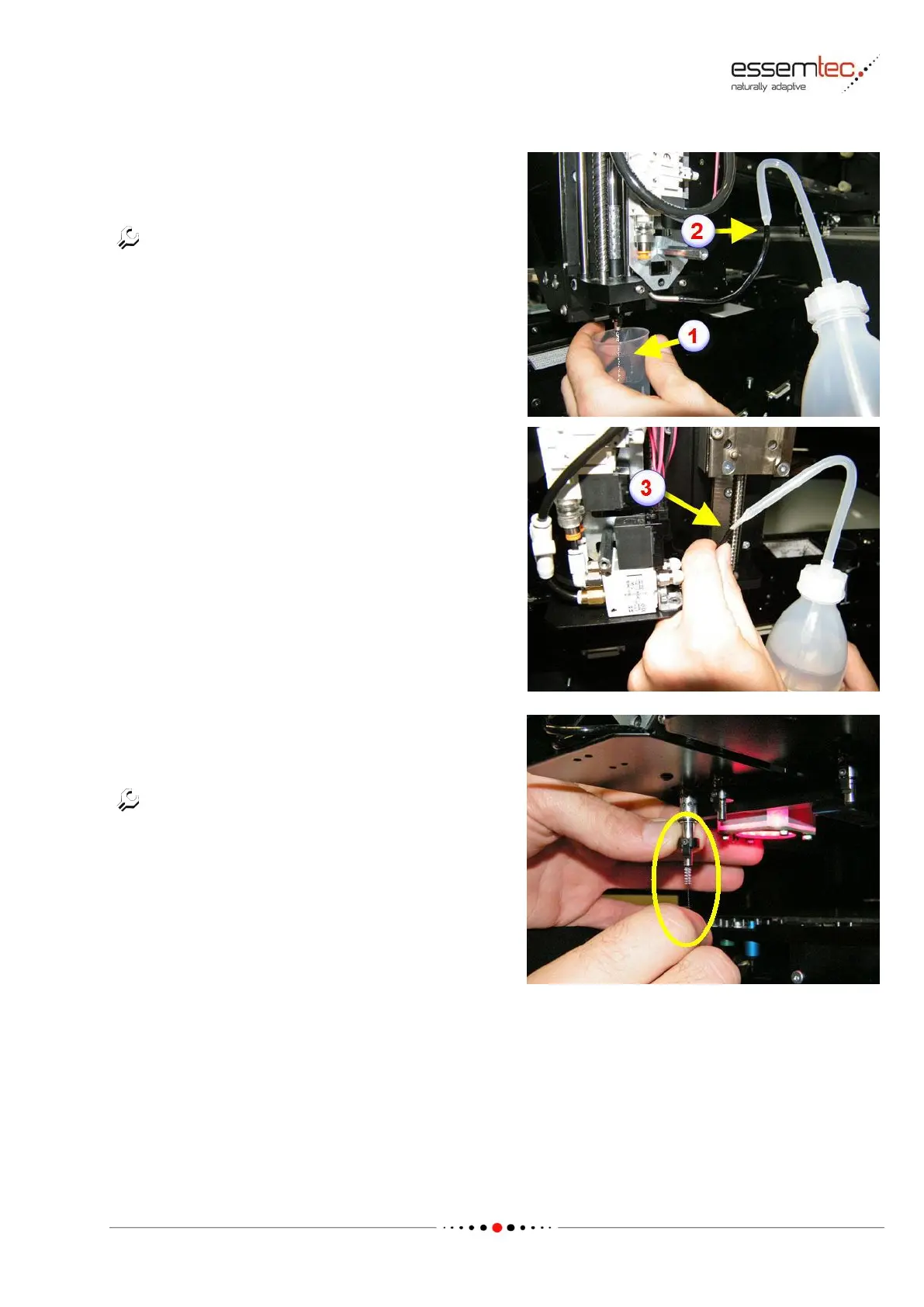

Clean the spindle tip by means of the conical

brush for spindle cleaning out of the

maintenance kit SP26/MAIN02 (see picture).

By means of the squeeze bottle, syringe or

similar dosing unit, press the Isopropanol or

methylated spirit through the first passage

again.

Afterwards plug in the vacuum hose on the first

valve for blowing out the cleaning liquid and

drying the passage.

Repeat above steps for all vacuum hoses, one by one.

Loading...

Loading...