234

POWERHEAD

POWERHEAD ASSEMBLY

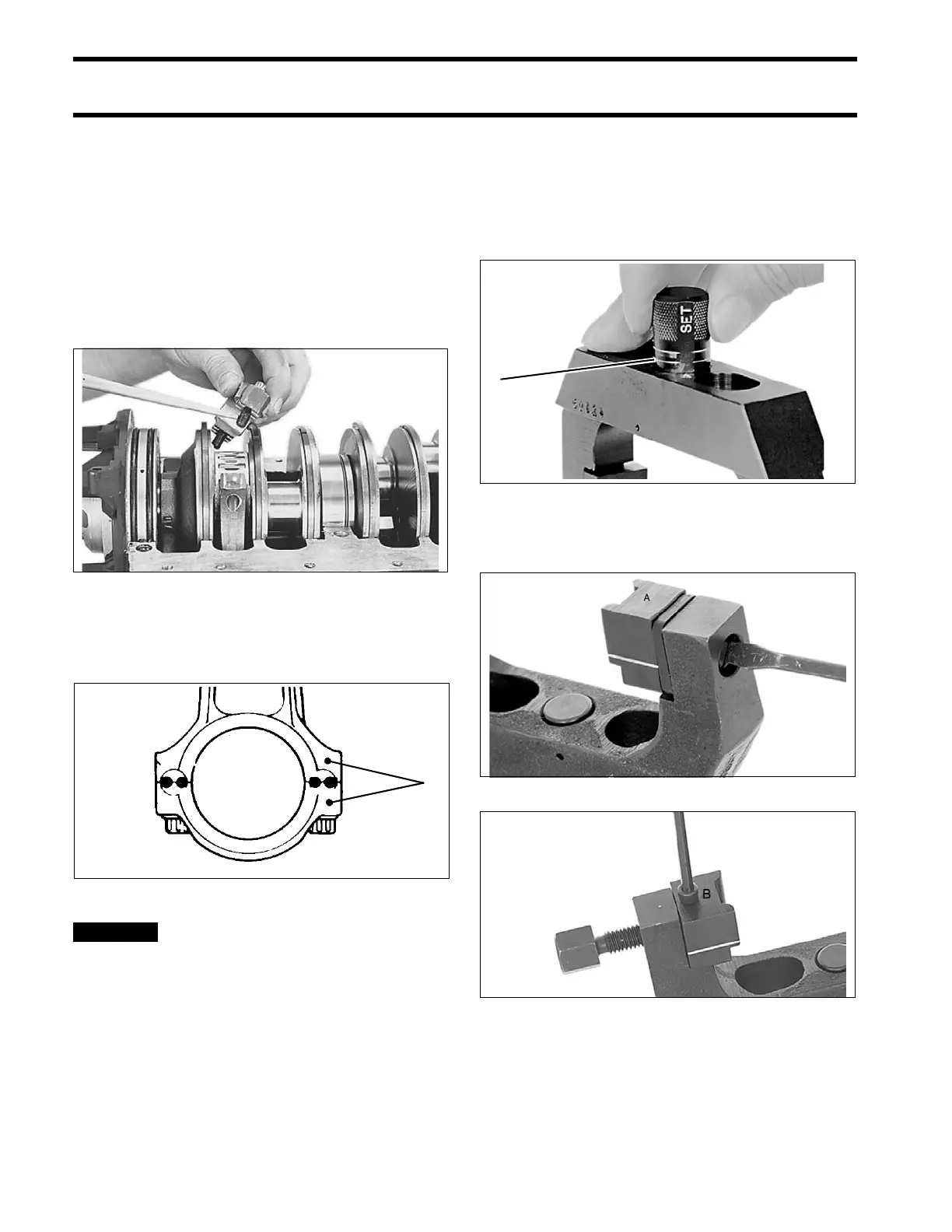

Lubricate rod cap screw threads and under screw

head mating surface with a light coat of Triple-

Guard grease. Apply outboard lubricant to screw

hole threads in rod, and to screw head mating sur-

face on cap.

Align dot on rod cap with dot on the connecting

rod.

Install rod cap screws finger tight (NO MORE than

6 in. lbs. (1 N·m) maximum).

IMPORTANT: Be sure alignment dot on rod cap

matches dot on rod and that both dots face fly-

wheel.

Tightening rod cap screws without

Alignment Fixture, P/N 396749, or using an

incorrect procedure could cause permanent

damage to the connecting rod and crankshaft.

To maintain accurate torque values, keep

torque wrench extension length to a minimum.

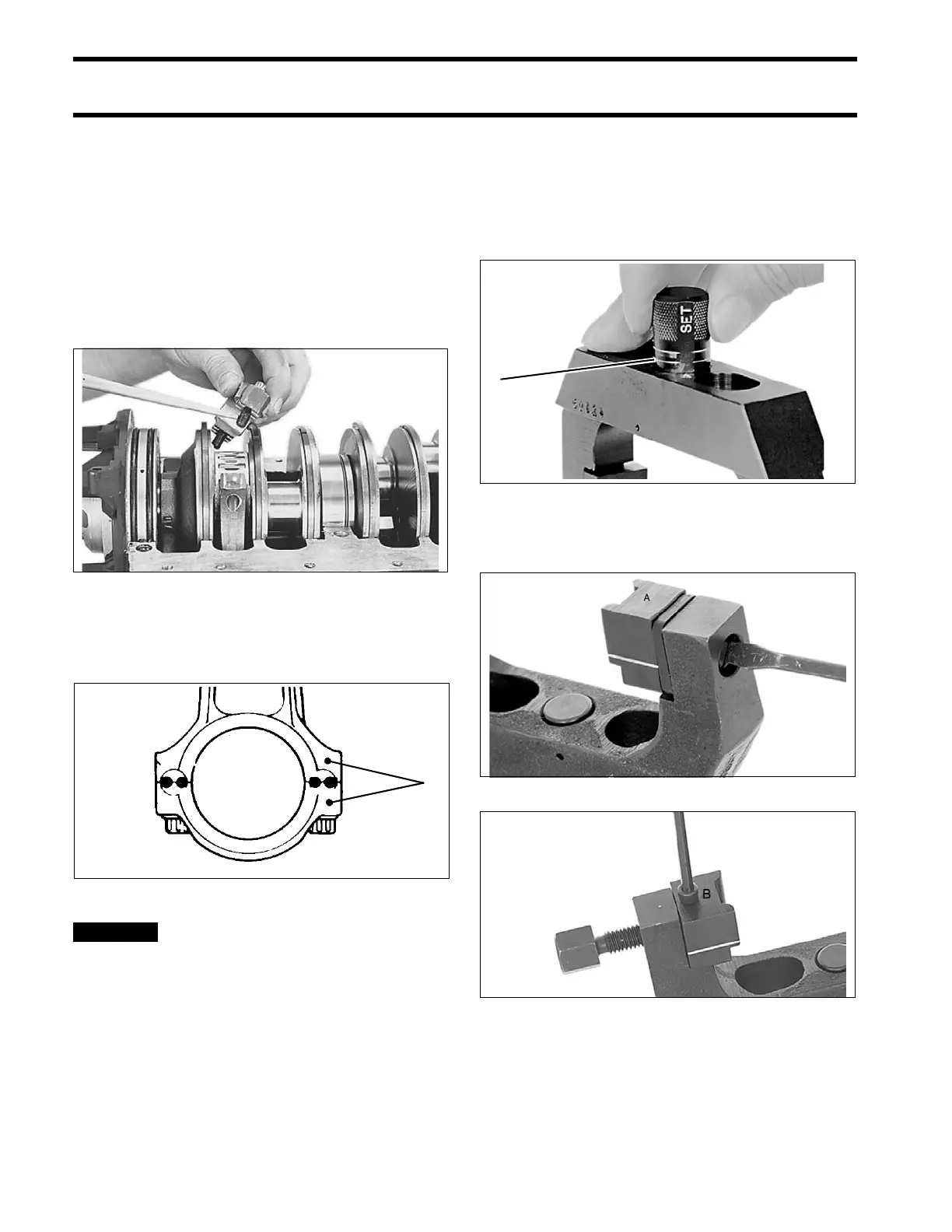

Install Rod Cap Alignment Fixture, P/N 396749,

before tightening rod cap screws. Align the flat

marked “SET” on the rod adjustment stop with the

arrow on the frame. Position the stop at the high-

est setting (two lines showing). Rotate adjustment

knob 180° to lock the stop in position.

Secure restraining jaw “A” and forcing jaw “B” to

frame.

31826

1. Alignment dots 53628

1. Adjustment stop, highest setting 2287

Restraining Jaw “A” 21591

Forcing Jaw “B” 21594

Loading...

Loading...