NEVER perform maintenance under the machine

when the engine is running. Always park the

machine on a leveled ground and shim the cylinders.

1. Place a proper container under the drainage plug of the fuel

tank (1).

2. Release the plug (1) and allow the sediment water to drain

until the clean fuel starts to drain.

3. Reinstall the drain plug and tighten it.

4. Repeat the operations above on the opposite side plug.

NOTE: The sediment water draining process on the fuel tank

should also be made when the equipment is not being

used for a long period of time.

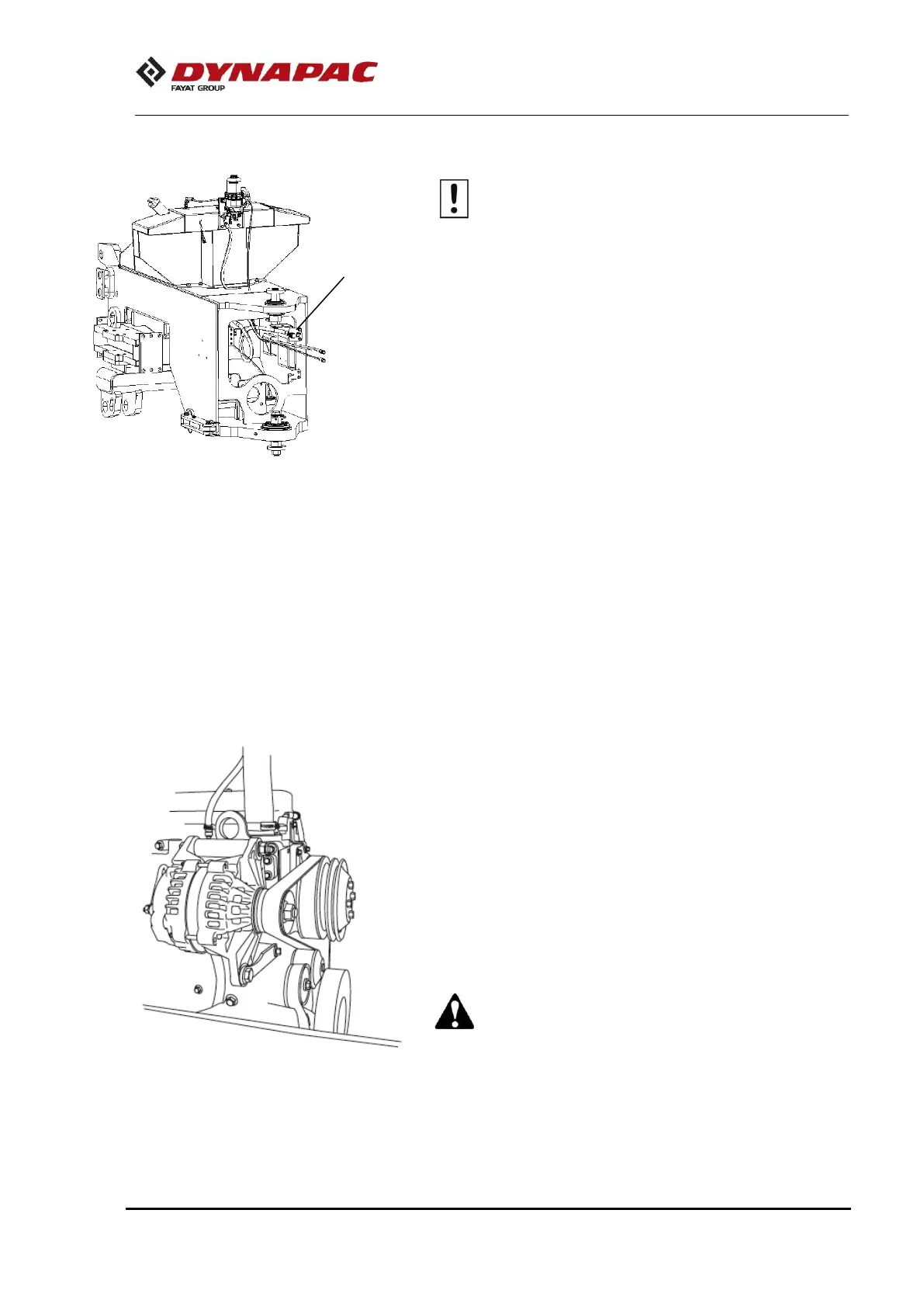

Check the alternator belt tensions (Tier IV Engine)

Checking the belt tension should be done with a belt tension

meter of tension type or Burroughs type.

A new belt should have a tension of 200 lb (890 N).

A used belt should have a tension of 80-160 lb (360-710

N).

NOTE: The belt is considered used after ten minutes of usage

or more.

OBSERVATION: This procedure is not applied on automatic

belt tensioners.

If the tension of a used belt is under the

minimum value, adjust it again to the maximum

value for used belts..

Loading...

Loading...