FRICK QUANTUM CONTROL PANEL

OPERATION

S90-010 O

Page 25

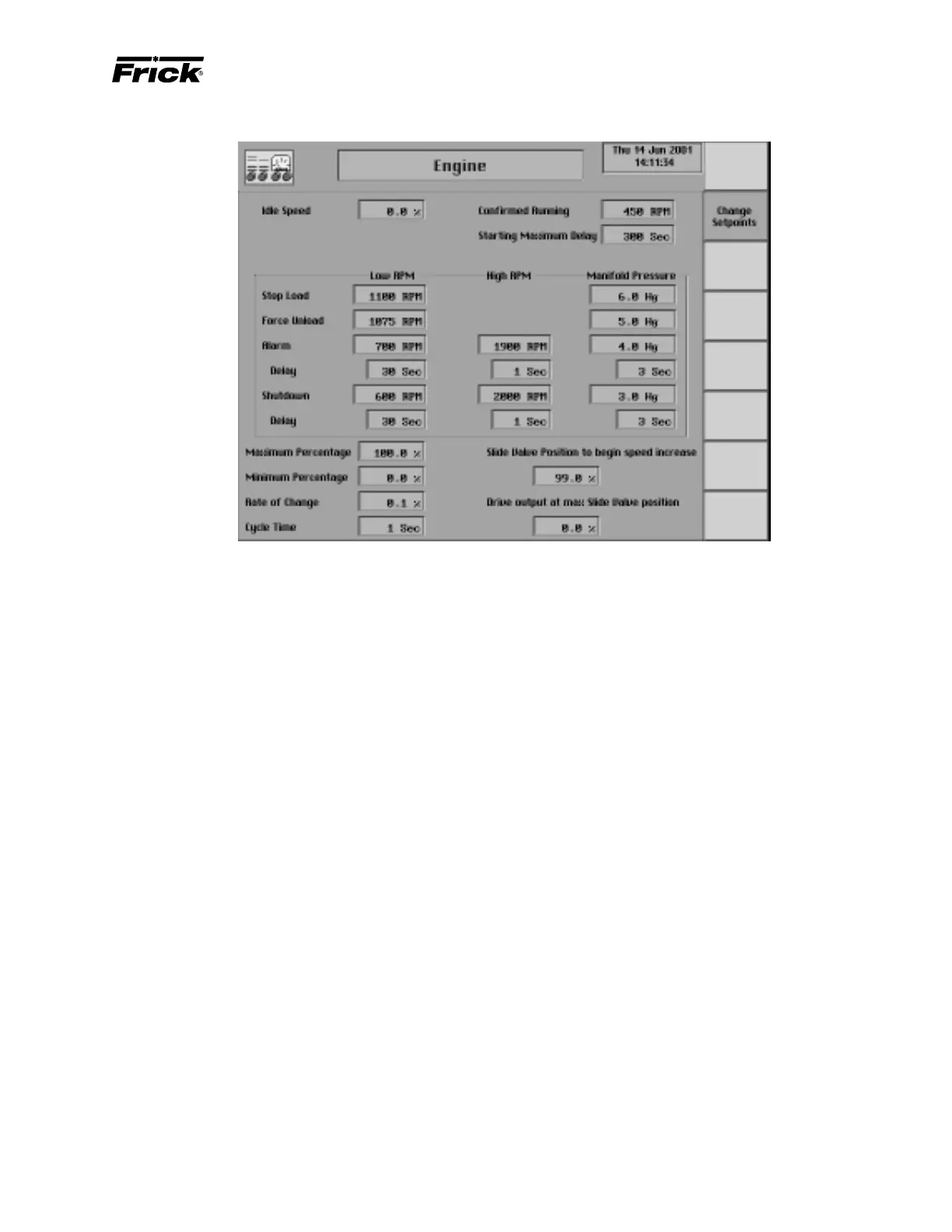

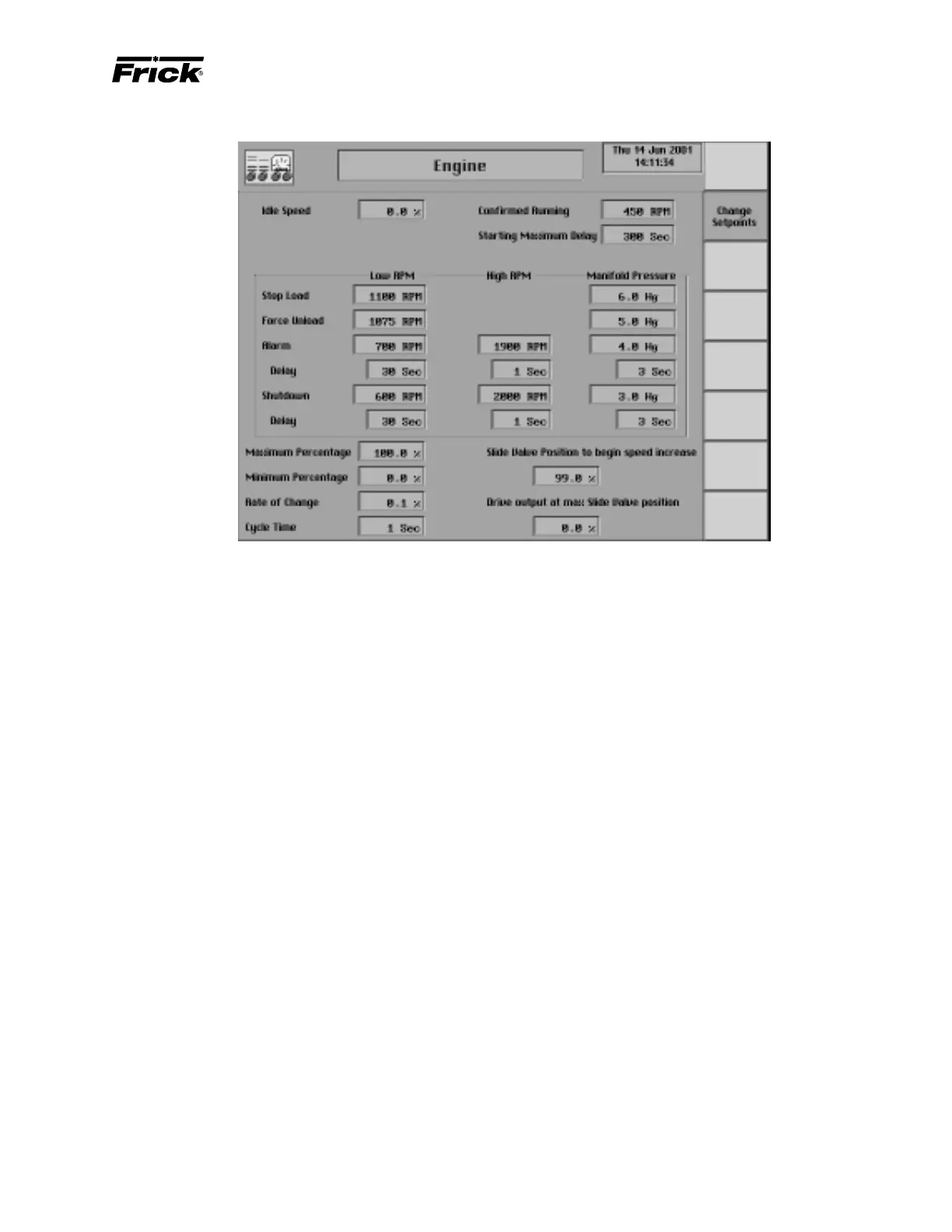

CONTROL SETUP - MOTOR CONTROL SETPOINTS - “Engine”

Hardware Signals

4 – 20 ma analog output - Signal from the Quantum to

provide the speed setpoint to the speed governing device.

The speed governing device’s controller (i.e. Electronic Gov-

ernor) and hardware will need to be configured to the mini-

mum and maximum desired speed. The minimum speed

will vary depending on compressor type, consult the factory

application assistance.

4 – 20 ma analog input - Analog input channel on the

Quantum to monitor the actual RPM’s of the drive. This sig-

nal can be sent to the Quantum from the speed governing

device if available or generated from a magnetic pickup

located on the flywheel teeth wired to a frequency to 4-20

ma converter.

Manifold Pressure (Engine only) - Pressure signal required

from the engine to detect and respond to overload

conditions.

Setpoints related to the Engine speed control output.

Maximum output - Setpoint used to select the maximum

operating speed. Selectable from 1-100% of the Quantum’s

4-20ma signal.

Minimum output - Setpoint used to select the minimum

operating speed. Selectable from 1-100% of the Quantum’s

4-20ma signal.

Rate of change - Setpoint used to adjust the speed changes

sent to the VFD based on the capacity control requirements.

Selectable from .1-25% of the 4-20ma signal.

Cycle Time - Setpoint used in conjunction with the “Rate of

change” setpoint to adjust the time between speed changes

sent to the VFD. Selectable from 1-30 seconds.

Slide Valve Position to begin Speed Increase - The Slide

Valve position which must be obtained before the speed

will begin to increase. Selectable from 0-100% of the com-

pressors Slide Valve position. This setpoint is used in con-

junction with the “Drive Output at Max SV position”.

Drive Output at Max SV position - The desired speed of

the engine/turbine when the Slide Valve position reaches

100%. This setpoint is selectable from 1-100% of the

Quantum’s 4-20ma signal and is used in conjunction with

the “Slide Valve Position to begin Speed Increase”.

High RPM Alarm - If the RPM is greater than or equal to this

setpoint, for the alarm time delay, an alarm occurs.

High RPM Shutdown - If the RPM is greater than or equal to

this setpoint, for the shutdown time delay, the compressor

will shut down.

High RPM Alarm Delay - The minimum time in seconds

that the RPM is greater than or equal to the High RPM

alarm setpoint before notification of the alarm.

High RPM Shutdown Delay - The minimum time in sec-

onds that the RPM is greater than or equal to the High RPM

shutdown setpoint before the compressor will shut down.

Low RPM Stop Load - If the RPM is less than or equal to this

setpoint, the compressor will be prevented from further load-

ing until the RPM is greater than this setpoint. This setpoint

helps avoid forced unloading.

Low RPM Force Unload - If the RPM is less than or equal to

this setpoint, the compressor will be forced to unload until

the RPM is greater than this setpoint. This setpoint helps

avoid a low RPM alarm or shutdown.

Low RPM Alarm - If the RPM is less than or equal to this

setpoint, for the alarm time delay, an alarm occurs.

Loading...

Loading...