FRICK QUANTUM CONTROL PANEL

OPERATION

S90-010 O

Page 57

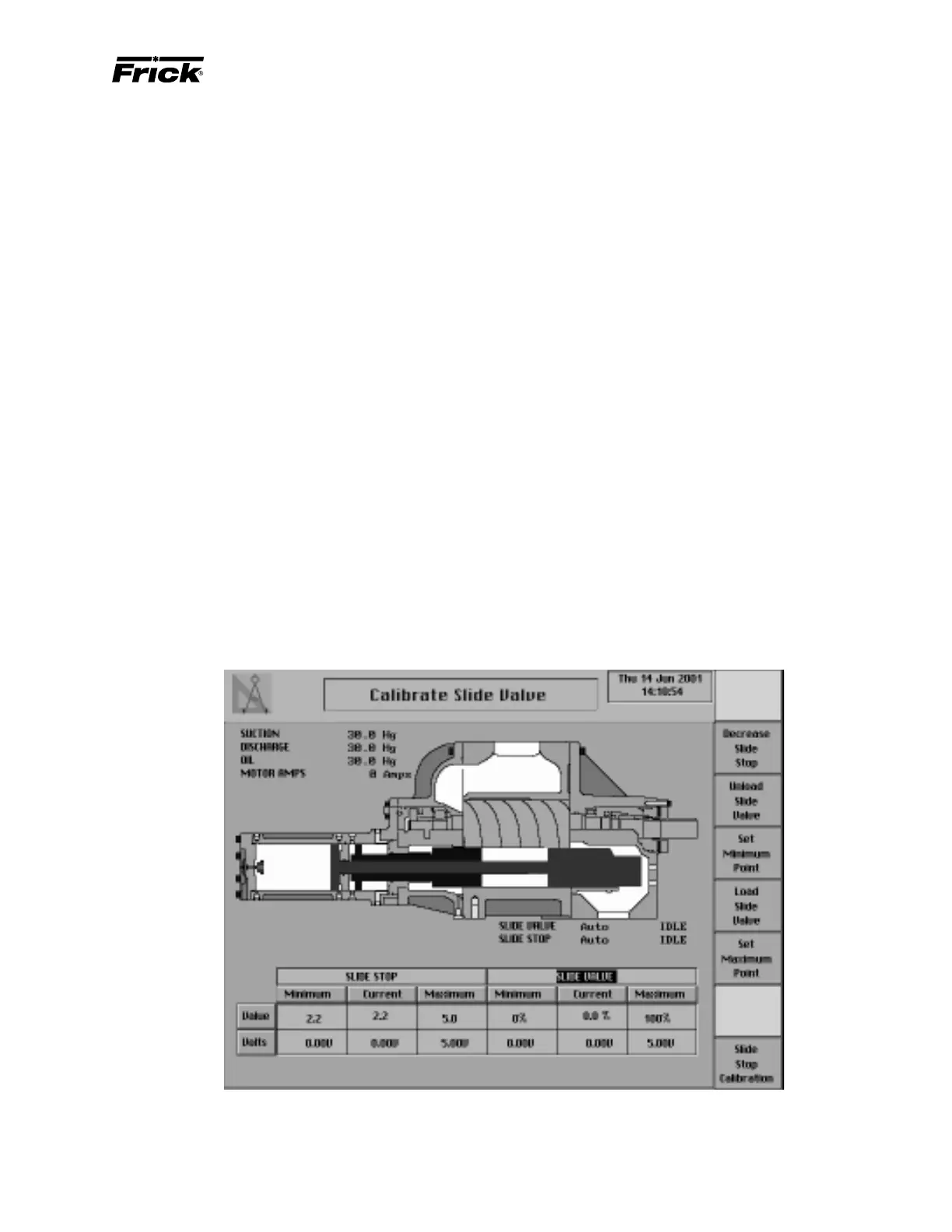

The “Calibrate Slide Stop” screen is shown if it applies to

the compressor model (Reference “Compressor Model Dif-

ferences”). It shows a pictorial representation of a Slide

Valve and Slide Stop. The Slide Valve and Slide Stop status

information, the Motor Amps reading, and the Suction, Dis-

charge, and Oil Pressure readings are shown here for quick

reference. The same information of the Slide Valve and Slide

Stop status box, shown on the Operating Status display, is

also shown here for quick reference. The screen heading

and the highlighted heading in the table, both depict what

is presently selected to be calibrated. The Slide Stop should

be calibrated prior to calibrating the Slide Valve. Calibrating

the slide stop requires setting the minimum and maximum

Slide Stop. The minimum Slide Stop value represents the

furthermost position the Slide Stop can be decreased to.

The maximum Slide Stop value represents the furthermost

position the Slide Stop can be increased to. The current

reading is the reading that changes when increasing or

decreasing the Slide Stop. An invalid reading is indicative

of the need to calibrate. The volts reading corresponds to

the metered voltage that is measured when the Slide Stop

is at the displayed position. The screen keys are positioned

in the order they should be used. ( The RWB model 355 and

283 are exceptions to this sequence order. With these the

[Decrease Slide Stop] should precede the [Unload Slide

Valve] ). The following keys are provided:

[Unload Slide Valve] - The initial selection of this key

will cause the Slide Valve position to continuously un-

load. Selecting this key again will stop the Slide Valve

at the current position. The slide valve position should

be unloaded until it does not interfere with decreasing

the Slide Stop.

[Decrease Slide Stop] - The initial selection of this key

will cause the Slide Stop to continuously decrease.

Selecting this key again will stop the Slide Stop at the

current position. To decrease the Slide Stop to the

minimum point, it is necessary that the Slide Valve po-

sition be increased until the Slide Stop will no longer

decrease.

[Set Minimum Point] - This key should be selected

when the Slide Stop is at the minimum position or low-

est voltage reading. The minimum Slide Stop value of

2.2 will then be set as the current Slide Stop value.

[Increase Slide Stop] - The initial selection of this key

will cause the Slide Stop to continuously increase. Se-

lecting this key again will stop the Slide Stop at the

current position.

[Set Maximum Point] - This key should be selected

when the Slide Stop is at the maximum position or

highest voltage reading. The maximum Slide Stop value

of 5.0 will then be set as the current Slide Stop value.

[Slide Valve Calibration] - Shows the Slide Valve cali-

bration screen.

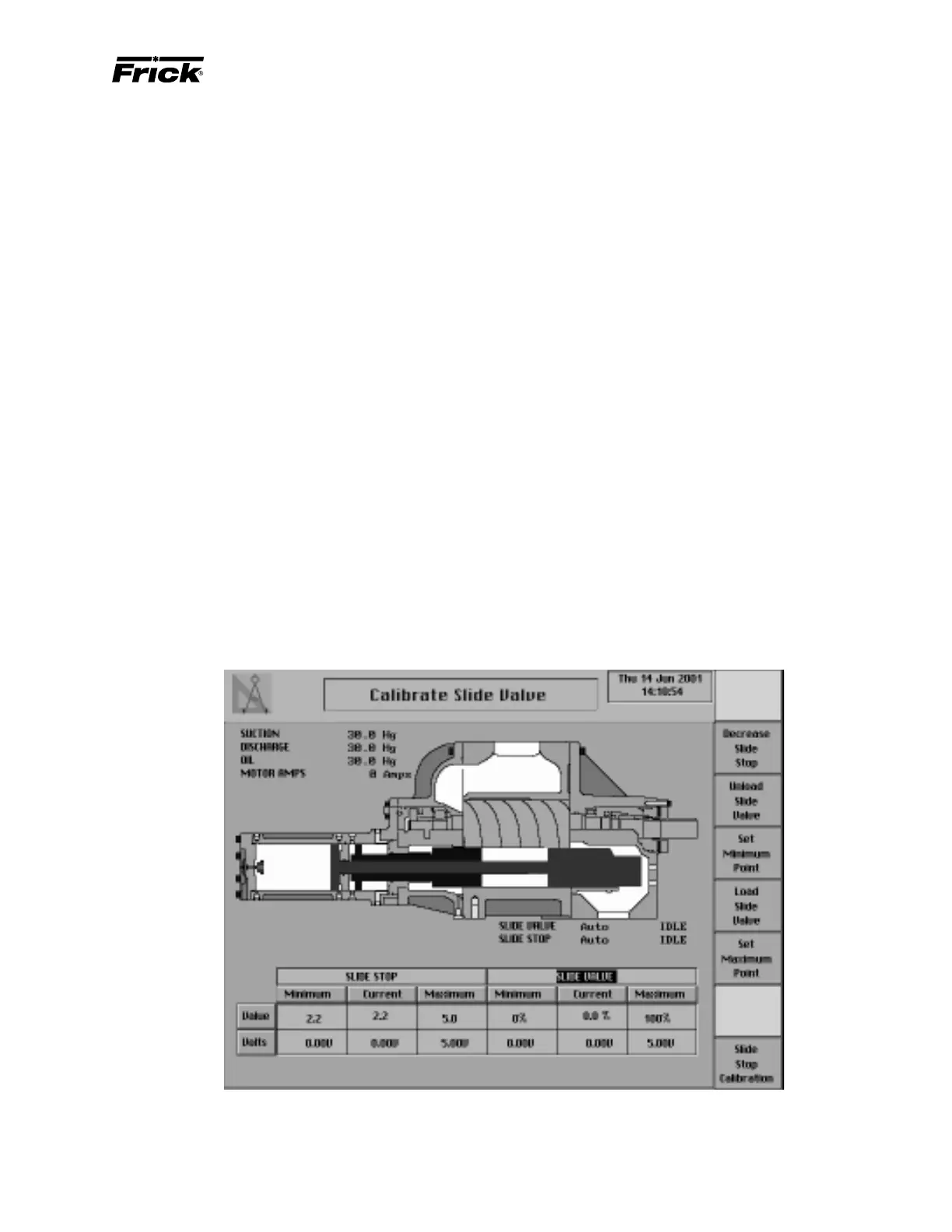

ANALOG CALIBRATION -

”Calibrate Slide Valve” SCREEN

This screen is shown if it applies to the compressor model

(Reference “Compressor Model Differences”). This screen

shows a pictorial representation of a sSlide Valve and Slide

Stop. Reference the picture of the “Calibrate Slide Stop”

screen. The Slide Valve and Slide Stop status information,

the Motor Amps reading, and the Suction, Discharge, and

Oil Pressure readings are shown here for quick reference.

The screen heading and the highlighted heading in the

Loading...

Loading...