FRICK QUANTUM CONTROL PANEL

OPERATION

S90-010 O

Page 30

The following displayed Oil Setpoints can not be modified:

Low Oil Pressure Alarm - If the Oil Pressure is less

than or equal to this setpoint, for the alarm time delay,

an alarm occurs.

Low Oil Pressure Shutdown - If the Oil Pressure is

less than or equal to this setpoint, for the shutdown

time delay, the compressor will shutdown.

Low Oil Pressure Alarm Delay - The minimum time in

seconds that the Oil Pressure is less than or equal to

the Low Oil Pressure Alarm setpoint before notification

of the alarm.

Low Oil Pressure Shutdown Delay - The minimum

time in seconds that the Oil Pressure is less than or

equal to the Low Oil Pressure Shutdown setpoint be-

fore the compressor will shut down.

Low Oil Pressure Alarm and Shutdown - Is deter-

mined by the type of pump and its running mode, and

from the pressure differential of the Oil Pressure read-

ing above or below the Discharge Pressure reading.

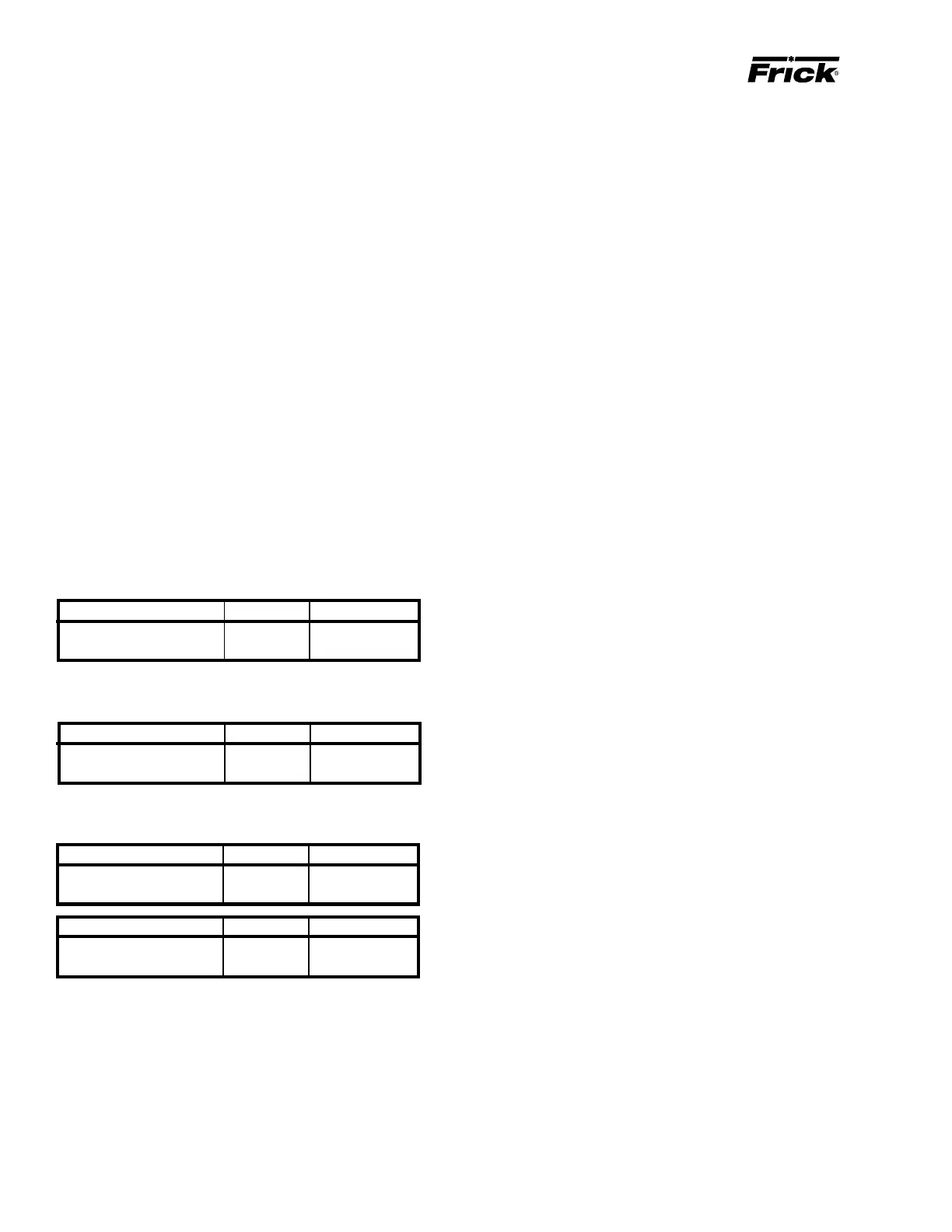

The following tables show the setup of the Oil Setpoints that

are only modified:

Running Full Lube Pump and Running Cycling Pump Oil

Pressure - Discharge Pressure = Oil Pressure Differential

Alarm Shutdown

Oil Pressure Differential 10 PSID 5 PSID

Time Delay 30 sec. 10 sec.

Other Manufacture’s Compressor Pump (Full Lube) Oil Pres-

sure - Discharge Pressure = Oil Pressure Differential

Alarm Shutdown

Oil Pressure Differential 25 PSID 20 PSID

Time Delay 5 sec. 5 sec.

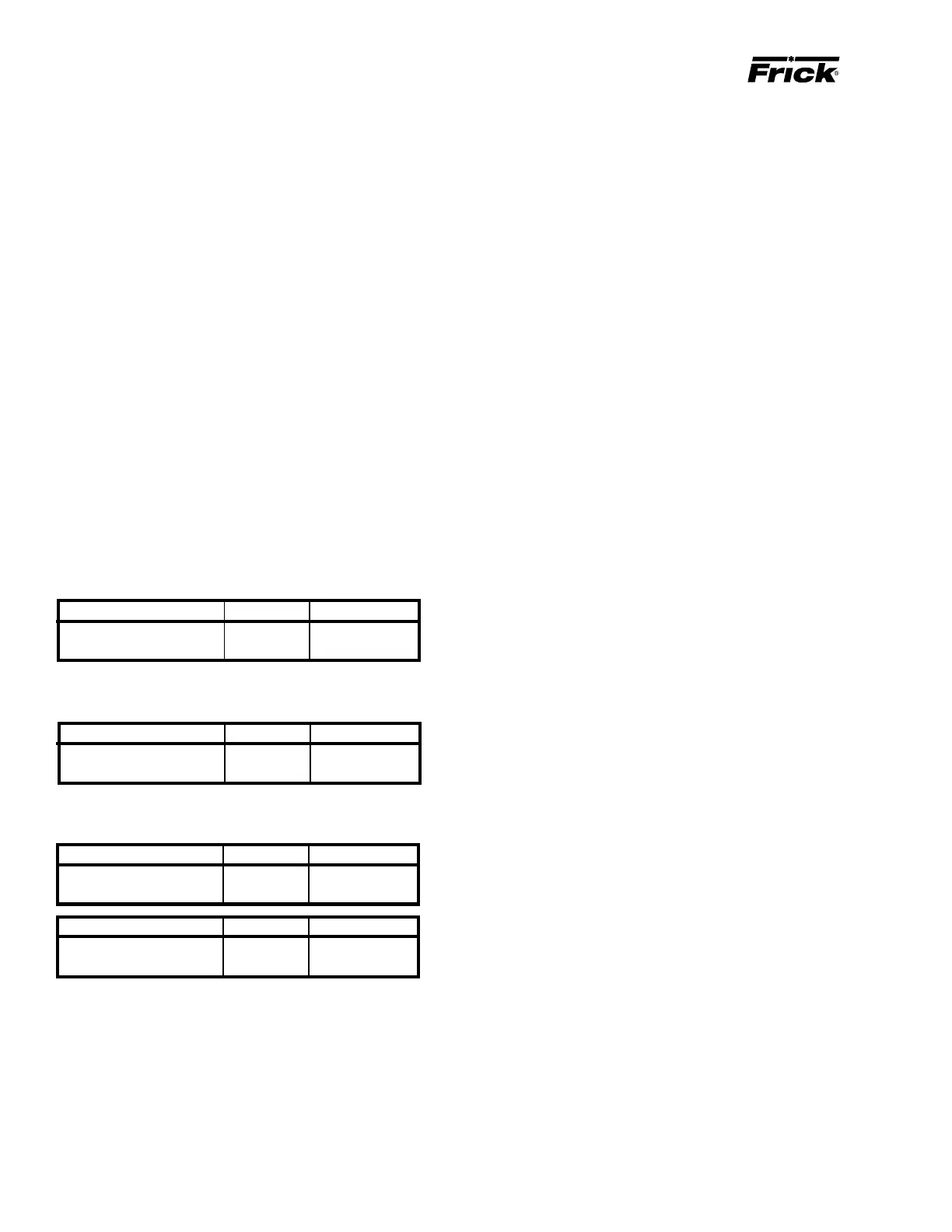

Prelube Pump and Not Running Cycling Pump

Discharge Pressure - Oil Pressure = Oil Pressure Differential

RWB II Alarm Shutdown

Oil Pressure Differential 25 PSID 30 PSID

Time Delay 30 sec. 10 sec.

RXF and RXB Alarm Shutdown

Oil Pressure Differential 35 PSID 40 PSID

Time Delay 30 sec. 10 sec.

Additionally a safety check is made for low oil flow that will

stop the compressor from loading or force the compressor

to unload. This check is made only for a RWB with prelube

or a RXB with no pump:

• If [Oil Pressure <= (1.5 x Suction Pressure) + 10 lb] then

the compressor will be forced to unload to 50% slide

valve. If this condition is reached the message “Forced

Unload - Low Oil Flow” is shown on the “Operating

Status” screen.

• If [Oil Pressure <= ((1.5 x suction pressure) + 15 lb) and

(slide valve >= 48 %)] then the compressor will be

prevented from further loading. If this condition is

reached the message “Stop Load - Low Oil Flow” is

shown on the “Operating Status” screen.

The following special selections are on this screen:

[Main Oil Injection] - This selection is only available if

it was enabled in Factory Setup. The following Oil

Setpoints are on this screen:

On at Discharge Temperature - If the high stage

compressor is running and the Discharge Tempera-

ture is greater than or equal to this setpoint, for the

time delay, the Main Oil Injection Discharge Tem-

perature output on digital board #2 is energized.

Delay - The minimum time in seconds that the Dis-

charge Temperature is less than or equal to the

“On at Discharge Temperature” setpoint before the

Main Oil Injection Discharge Temperature output

on digital board #2 is energized.

[Liquid Injection] - This selection is only available if the

compressor has Liquid Injection Oil cooling and it was

enabled through Factory Setup. This selection displays

the “Liquid Injection Cooling” screen. Liquid Injection

controls the supply of liquid refrigerant to the compres-

sor. Liquid Injection is off (the solenoid is closed) if the

compressor is off. This screen has the following

setpoints:

Oil Temperature On at - While the compressor is

running, if the Oil Temperature equals or exceeds

this setpoint, for the delay time, the Liquid Injec-

tion output will be energized or turned on to open

a liquid valve. If the output is energized it will be

de-energized or turned off, if the Oil Temperature

is 1°C below this setpoint.

Oil Temperature Delay - The minimum time in sec-

onds that the Oil Temperature is greater than or

equal to the Oil Temperature “On at” setpoint when

the compressor is running, before the Liquid In-

jection output is turned on.

Loading...

Loading...