49

16.5 O2 sensor inputs #1 and #2

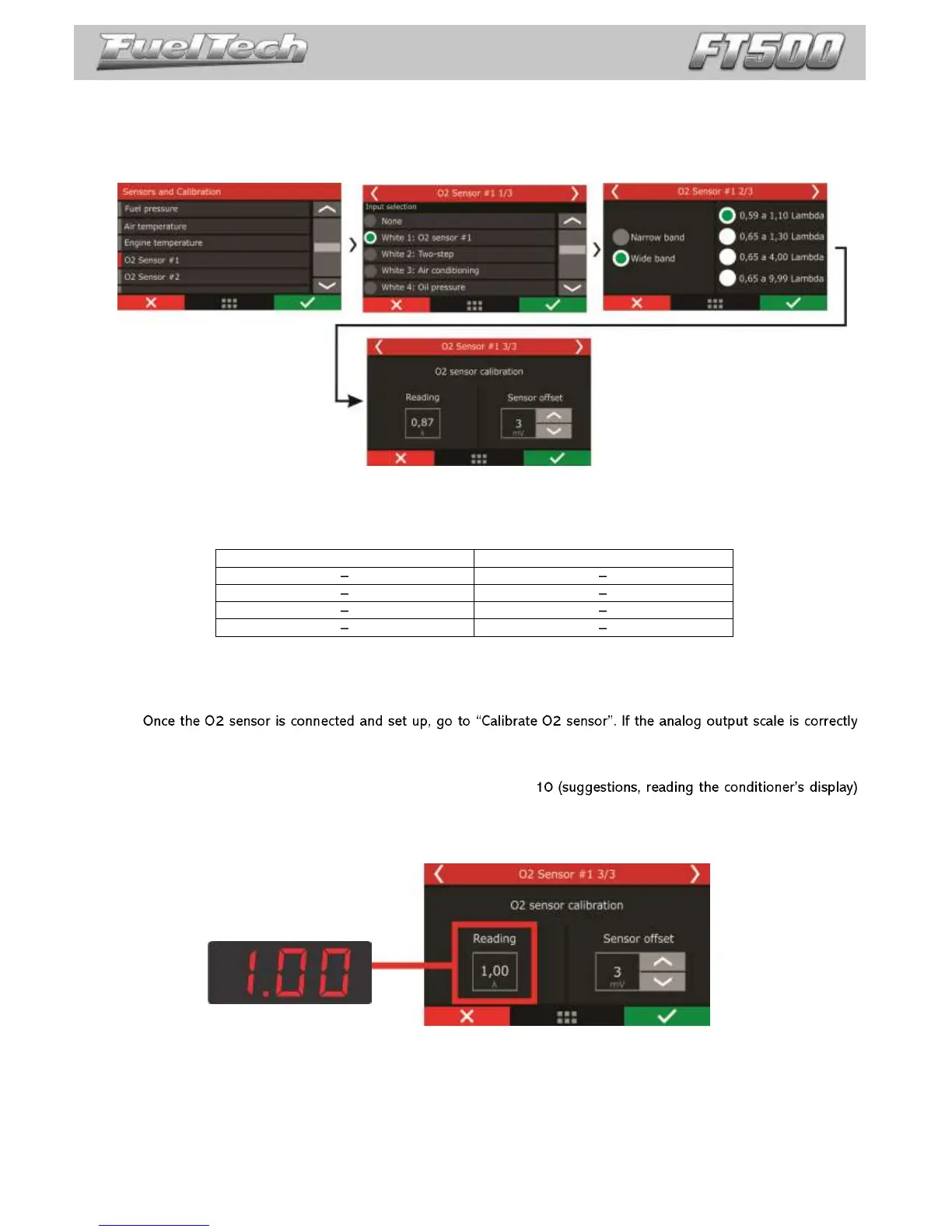

O2 sensor signal input can be setup on any sensors input of this ECU. It is even possible to read two O2 sensors

simultaneously and show them on the screen. For wide band O2 sensors, it is necessary to use a wide band conditioner,

for narrow band O2 sensors, direct connection is allowed.

Make sure the O2 sensor connection is exactly as described in chapter 13.7.

For wide band O2 sensors, the readings on-screen can be shown on Lambda or Gasoline AFR. The use of a wide

band conditioner is mandatory (FuelTech WB-O2 Slim or WB-O2 Datalogger), and its analog output scale must be

informed during this configuration.

Compatible analog output scales are:

Check your conditioner analog output, as there are some not compatible with this ECU.

For narrowband O2 sensors, the readings are shown in Volts.

O2 sensors #1 and #2 calibration

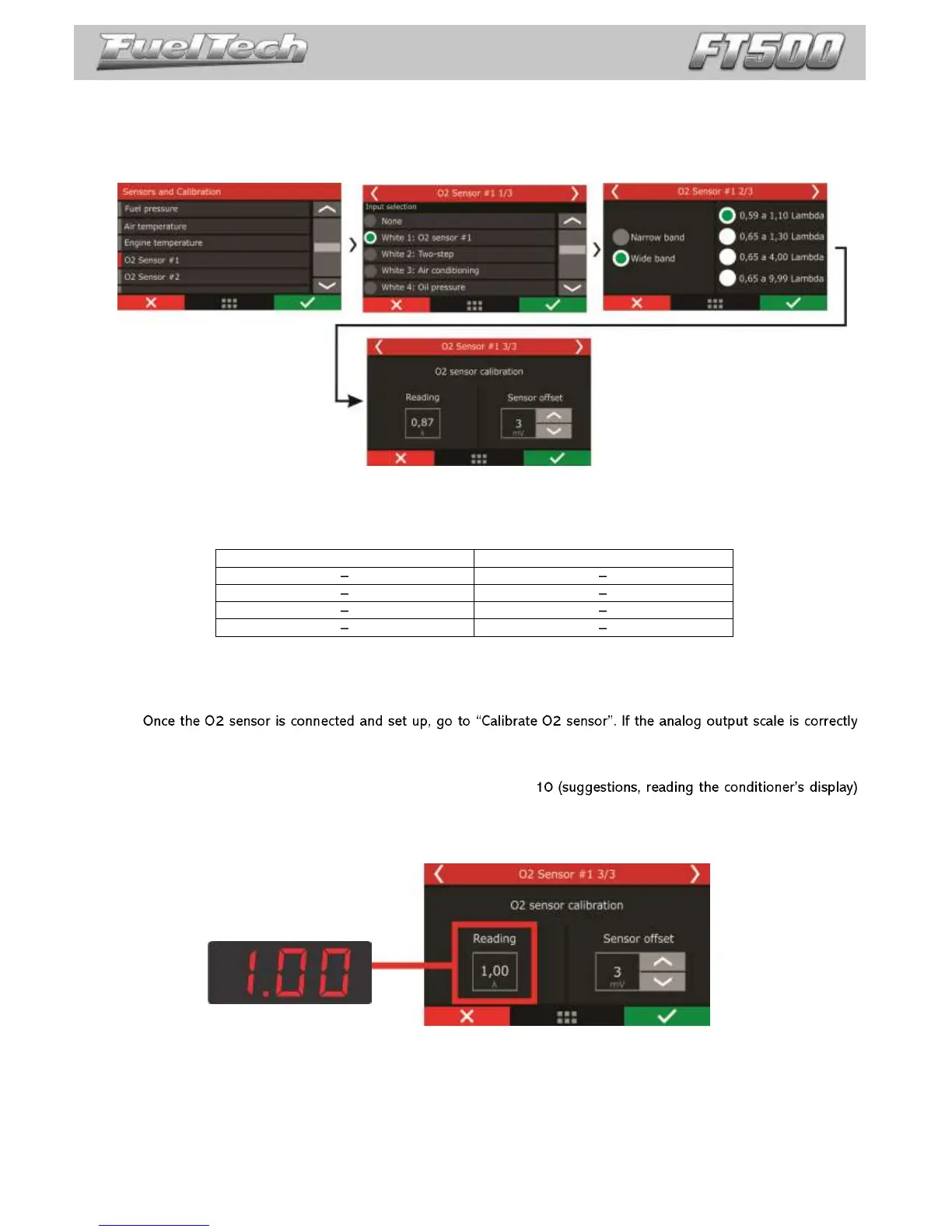

set up, the compensation value will be low or not needed.

To calibrate the O2 sensor, proceed as follows:

1. With the engine running, stabilize O2 readings on 0.90, 1.00, 1.

and compare it to the readings on the ECU display.

2. Adjust the offset until the values are equal. Compare O2 readings on other lambda ranges, to make sure the

calibration is ok.

Adjust the offset value until the value displayed on FT500 is equal to the value displayed by the O2 sensor conditioner

Loading...

Loading...