84

26 Rotary engines setup

The crank angle sensor (CAS) has two (2) trigger wheels

that provide different signals to the ECU. As shown in picture, the

bottom wheel is a 24 teeth trigger that provides the RPM signal and

position of the eccentric shaft. The top wheel is a 2 teeth trigger

that provides information of the position of the rotor.

FuelTech ECU will control the ignition timing using the

reference of the 24 tooth wheel to spark the leading coil. All ignition

timing programmed in the tables is referenced to the leading coil.

Trailing coil will be fired using the programmed timing split

parameter. This means that if the ignition timing in the main table is

0° and timing split is 10 °, the ECU will fire the leading coil at 0°

and the trailing coil 10° after leading coil was fired.

26.1 Crank angle sensor installation and alignment

The Crank Angle Sensor needs to be installed in the engine at 0° (top dead center position). To align it, follow this

quick step by step:

1. Use your ignition timing marks in the damper to align the eccentric to TDC. The ignition timing mark to be used is

shown below.

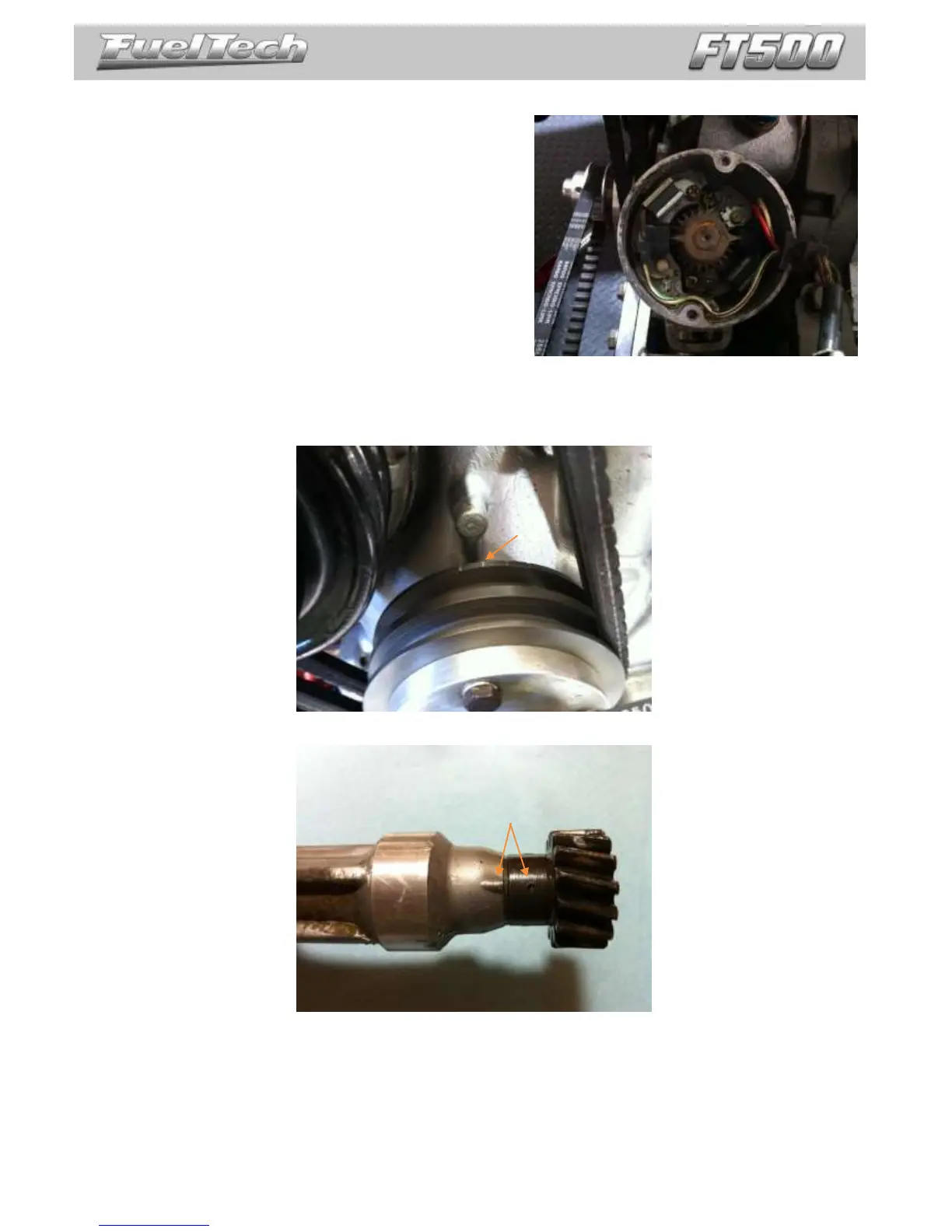

2. Align the Crank Angle Sensor to 0° using the mark in the shaft.

3. Install and tighten the Crank Angle Sensor in the engine. After the steps above are correctly followed, the Crank

Angle Sensor should be aligned at TDC with the eccentric shaft.

Loading...

Loading...