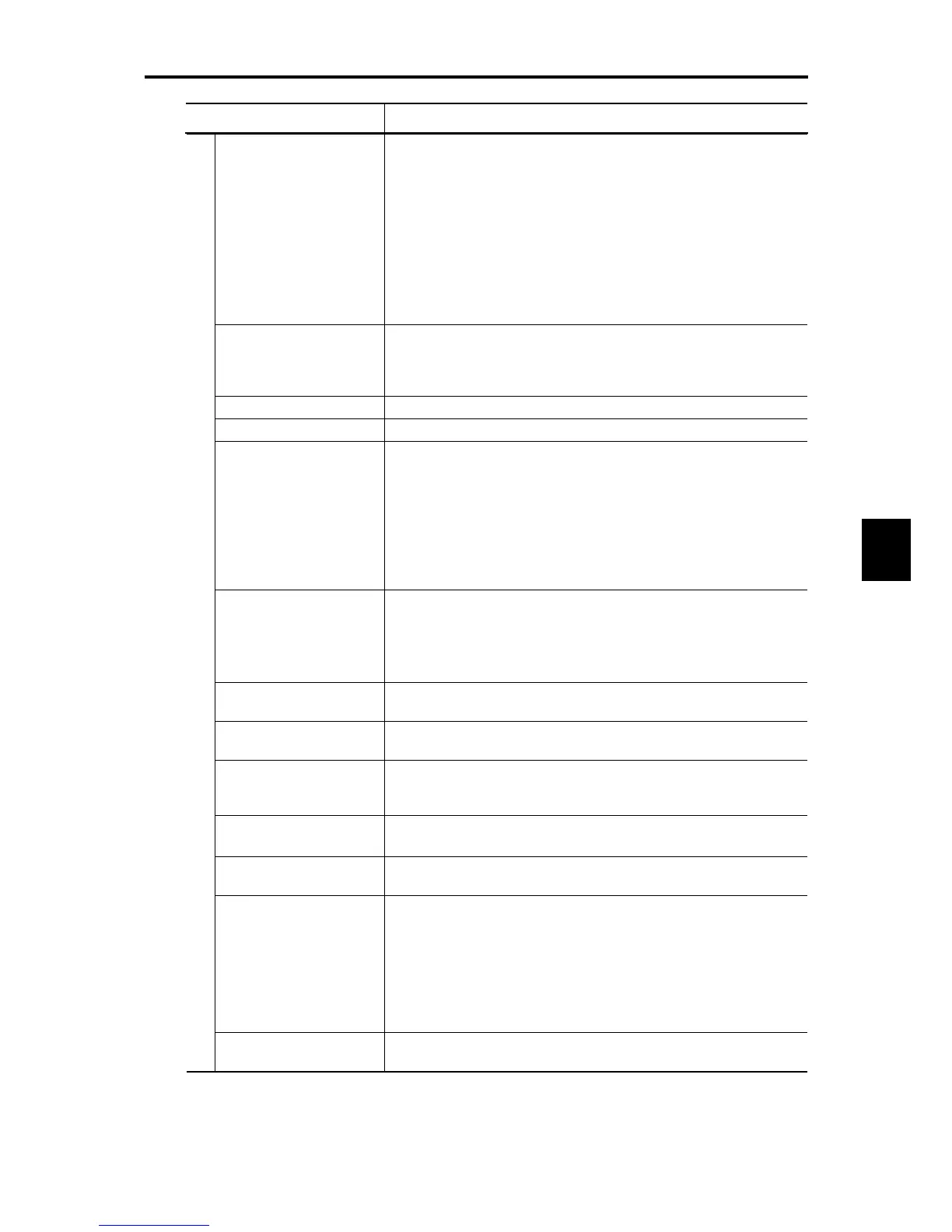

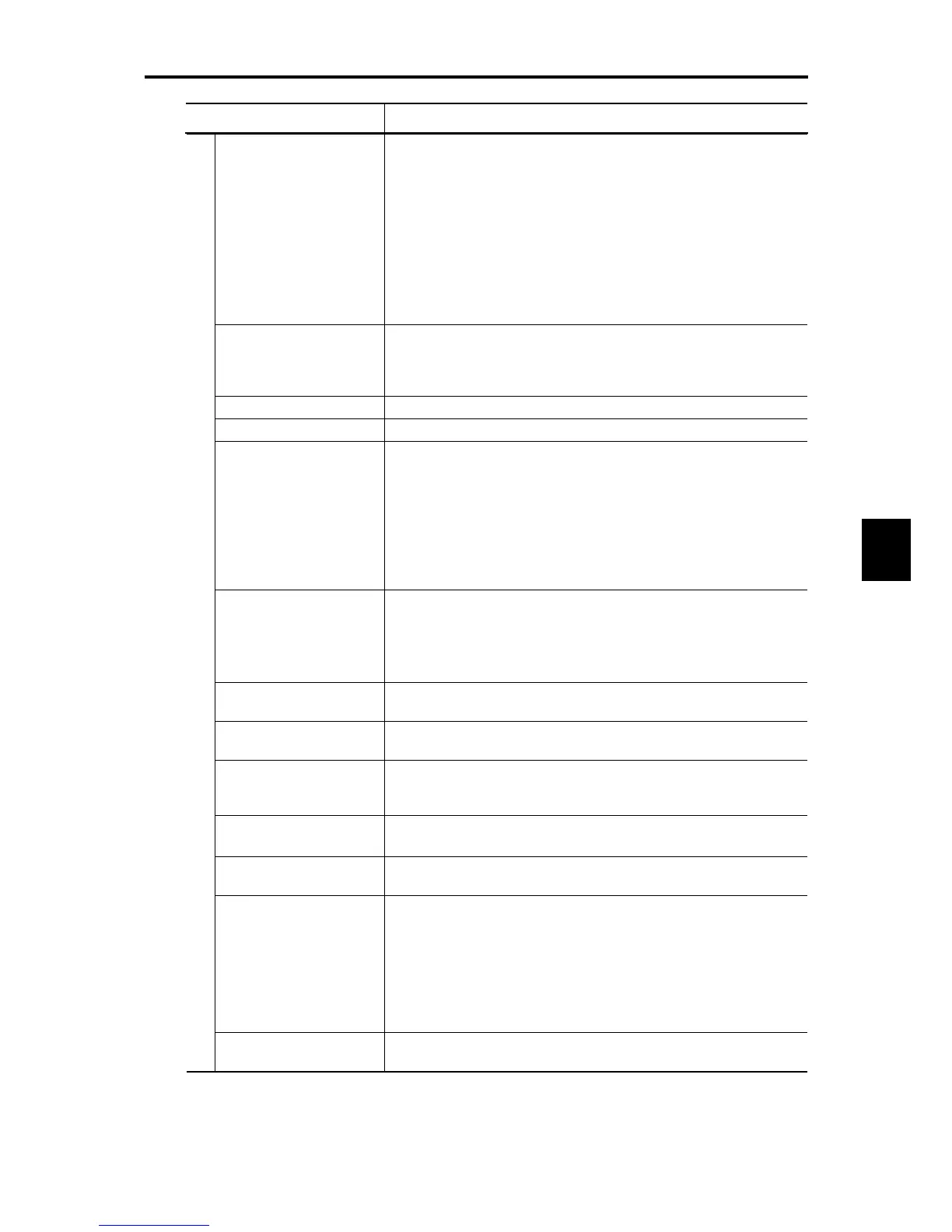

8.3 Common Specifications

8-9

Chap. 8 SPECIFICATIONS

Restart after momentary

power failure *1

• Trip at power failure: The inverter trips immediately after power failure.

• Trip at power recovery: Coast-to-stop at power failure and trip at power

recovery

• Deceleration stop: Deceleration stop at power failure, and trip after

stoppage. *2

• Start at the frequency selected before momentary stop: Coast-to-stop at

power failure and start after power recovery at the frequency selected before

momentary stop.

• Start at starting frequency: Coast-to-stop at power failure and start at the

starting frequency after power recovery.

Current limit *1

(Hardware current limiting)

Hardware current limiting is used avoiding over current tripping of the

inverter, when impact load change or momentary power failure that can be

responded software current limiting. (Hardware current limiting can be

inactive.)

Slip compensation *1 • Compensate the lowering the motor speed and get the stabilized operation.

Current limiter • Control output current so that output current is preset limiting value or less.

PID control

PID control for process control is possible.

• PID command: Keypad, Analog input (Terminal 12,C1), RS-485

communications

• Feed back value: Analog input (Terminal 12,C1)

• Accessory functions

Stop for Slow flow rate function, Normal operation/inverse operation

Integration reset/hold

Automatic deceleration

• If the calculated torque exceeds automatic deceleration level, the inverter

avoids overvoltage trip by automatically controlling the frequency. *1

• If the DC link bus voltage exceeds the overvoltage limitation level during

deceleration, the inverter automatically prolongs the deceleration time to

three times to avoid overvoltage trip.

Deceleration characteristics

Make the motor loss increase during deceleration so as to reduce the

regenerative energy from motor and avoid Overvoltage trip.

Auto-energy saving

operation *1

Control the output voltage so as to minimize the sum of motor loss and

inverter loss at constant speed.

Active drive

The output frequency is automatically reduced to suppress the overload

protection trip of the inverter caused by an increase in the IGBT junction

temperature or the ambient temperature, motor load or the like.

Off-line tuning *1 Tunes r1, Xσ, and no-load current.

Tunes r1, Xσ, no-load current, and slip frequency. *2

Cooling fan ON/OFF control

Detects inverter internal temperature and stops cooling fan when the

temperature is low.

Second motor parameters • A single inverter can drive two motors by switching.

Only induction motor can be set as second motor.

The function data set for second motor are base frequency, rated current,

torque boost, Electronic overload protection for motor, slip compensation,

etc.

• Second motor parameters can be preset in the inverter. Auto-tuning is

possible.

Control

Limiting the direction of the

motor rotation

Reverse rotation inhibited/Forward rotation inhibited selectable.

*1 Available only for induction motor drive.

*2 Available in the ROM version 0500 or later.

Item Explanation

Loading...

Loading...