8-20

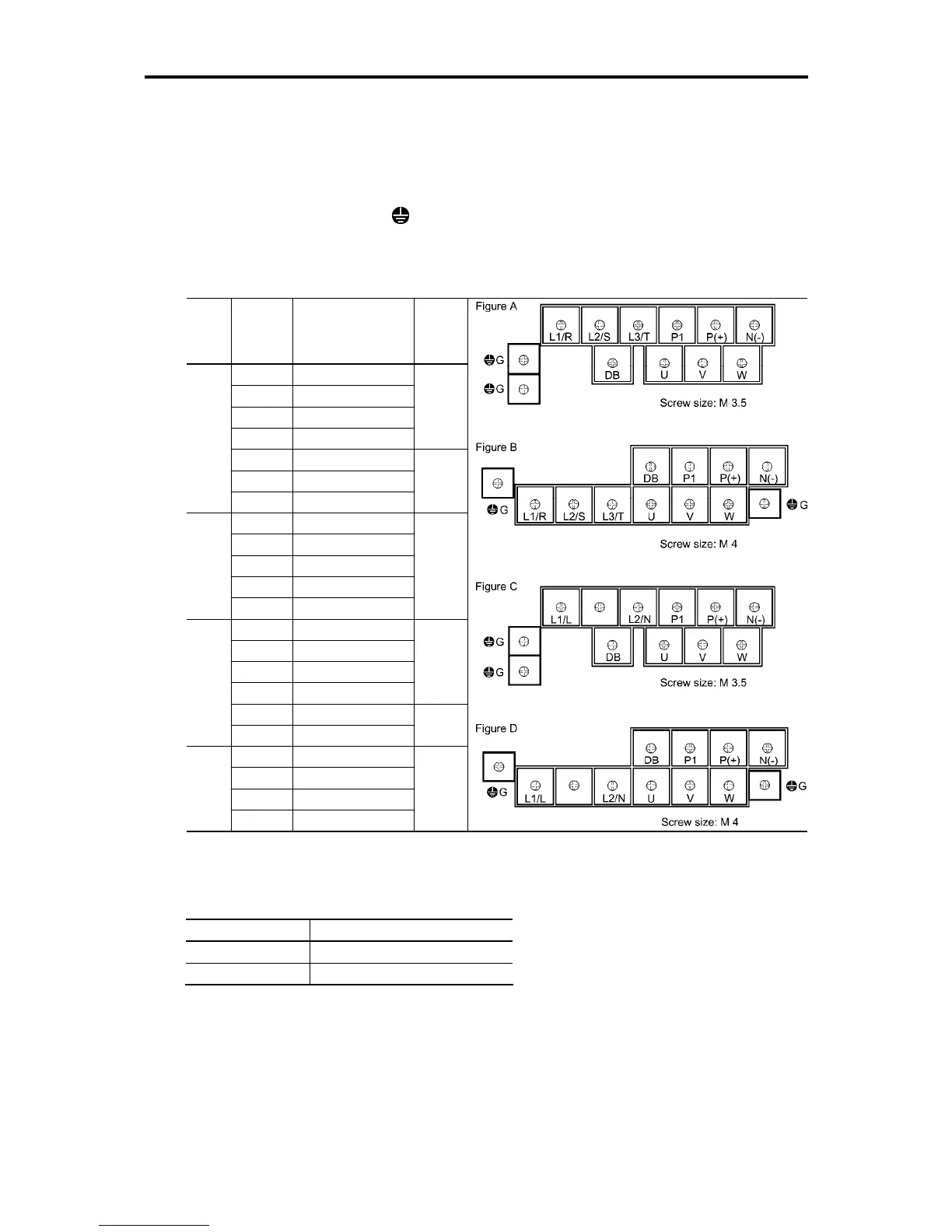

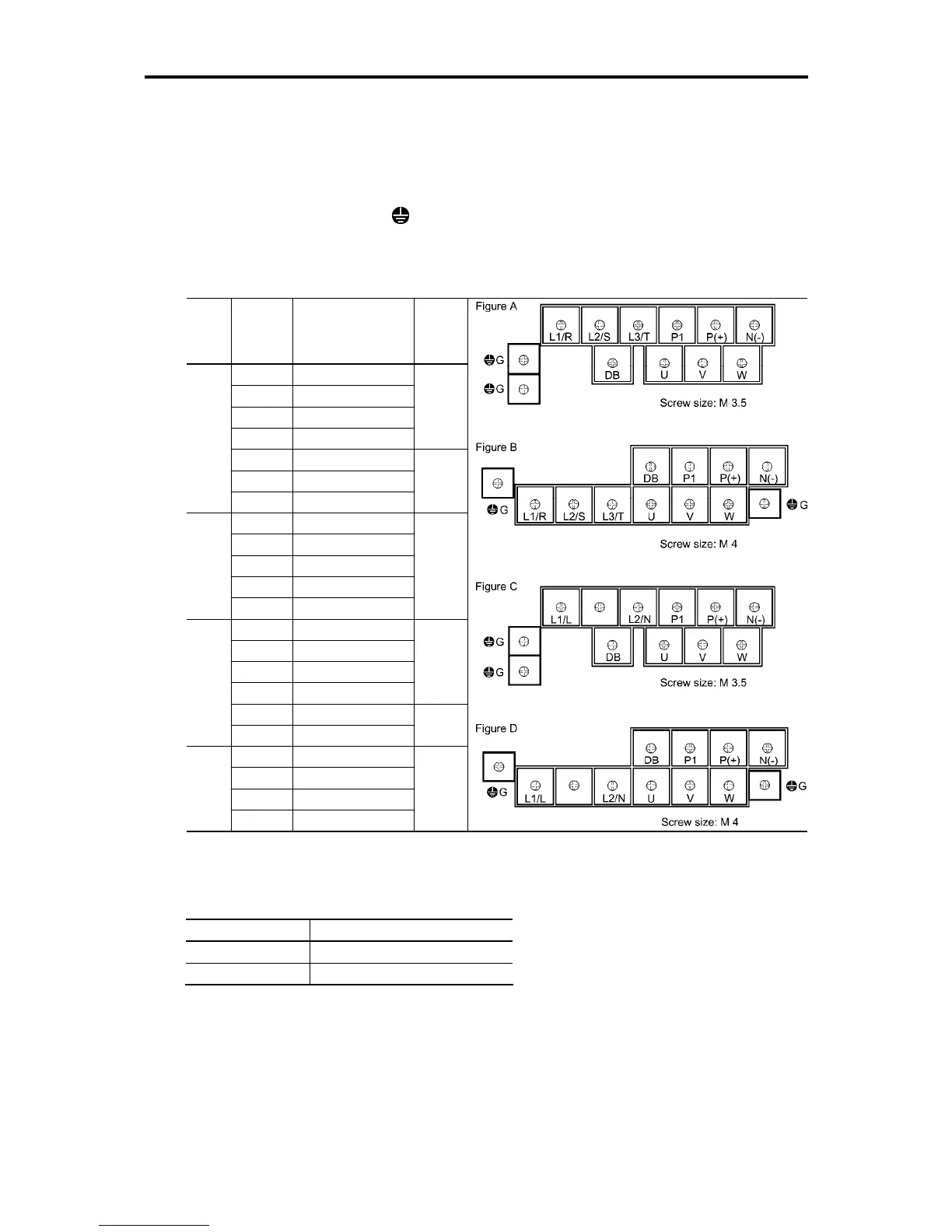

8.4.3 Terminal arrangement diagram and screw specifications

8.4.3.1 Main circuit terminals

The table below shows the main circuit terminal arrangements, screw sizes, and tightening torque.

Note that the terminal arrangements differ according to the inverter types. Two terminals designed for

grounding shown as the symbol,

in Figures A to D make no distinction between a power supply

source (a primary circuit) and a motor (a secondary circuit).

Table 8.1 Main Circuit Terminal Arrangements, Screw Sizes, and Tightening Torque

(0.1 kW to 3.7 kW class (1/8 HP to 5 HP class))

Power

supply

voltage

Applicable

motor

rating

kW (HP)

Inverter type Refer to:

0.1 (1/8) FRN0001C2S-2

0.2 (1/4) FRN0002C2S-2

0.4 (1/2) FRN0004C2S-2

0.75 (1) FRN0006C2S-2

Figure A

1.5 (2) FRN0010C2S-2

2.2 (3) FRN0012C2S-2

Three-

phase

200 V

0.75 (1) FRN0005C2S-6U

Figure C

Notes: 1) A box () in the above table replaces A, C, E, or U depending on the shipping destination.

2) A box () in the above tables replaces S (Basic type) or E (EMC filter built-in type) depending on the

enclosure.

Screw size Tightening torque

M3.5 1.2 N·m (10.6 lb-in)

M4.0 1.8 N·m (15.9 lb-in)

Loading...

Loading...