Maintenance – Checking – Cleaning GEDA

®

SUSPENDED WORKING PLATFORM AB 450 / 650

Assembly and Operating Manual

72 / 96 BL061 GB Edition 04/2016

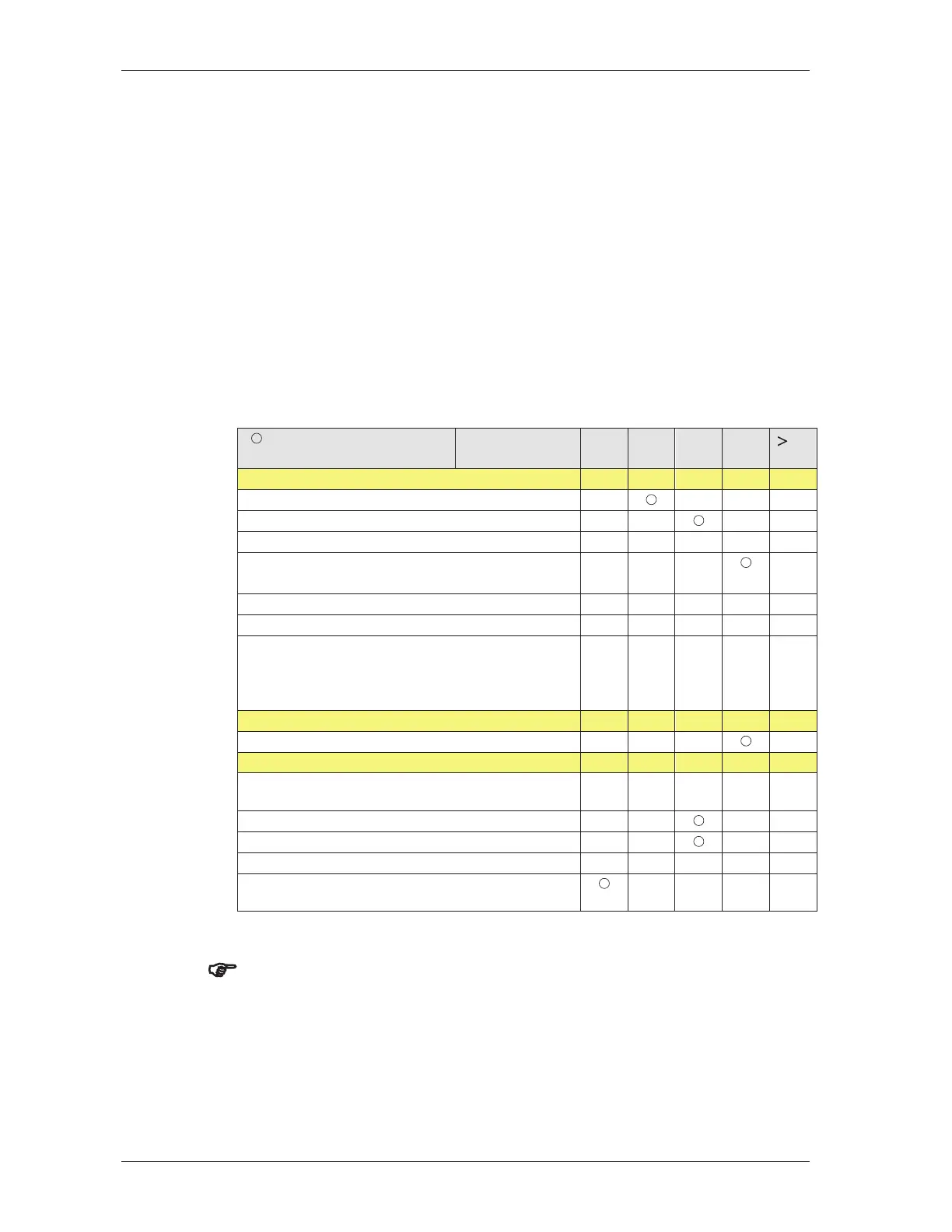

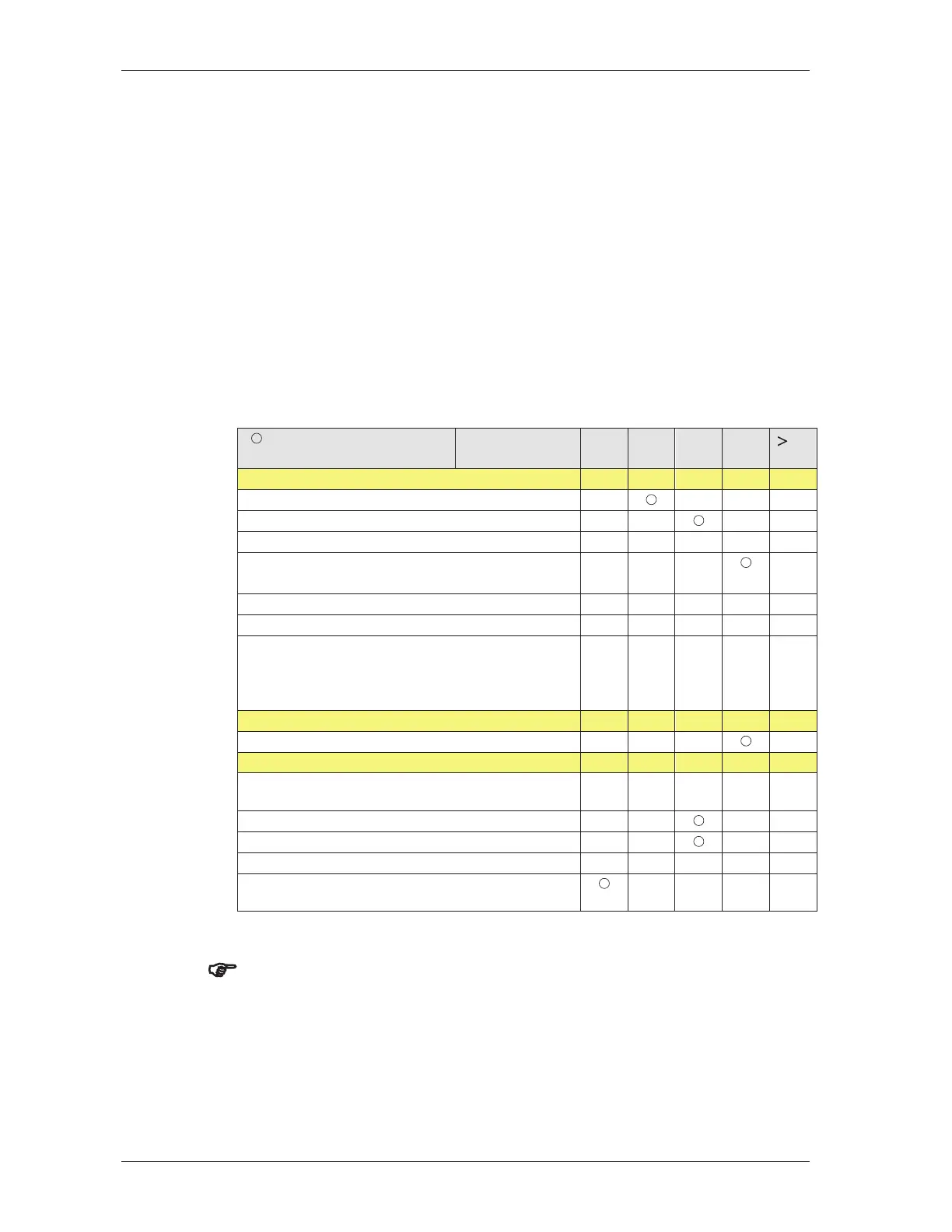

8.2 Maintenance schedule

The inspections to be carried out on a daily basis before the start of

operation are not included in the maintenance schedule. These are

described in the “Operation” chapter, because these checks are carried

out by the operating personnel.

The maintenance intervals given relate to one-shift operation (40 hours/

week). The intervals are to be modified according to any deviating

operating times. The following inspections always include a check for

proper function, wear, completeness and that there is no manipulation

present.

Abbreviations used in the maintenance schedule

W = Week / M = Month / Y = Year

z = Visual inspection /

Ŷ= Check

Check the control line for damage.

Abrasion protection for cables

Function test of the control location

Control devices, switching devices, limit

switches and sensors

Check/adjust the strength of the contact

Check the overload setting

Safety of electrical equipment for

machines [repetition test]

(protective earth testing, insulation measurement,

Dirt, moisture, scorched areas

Information signs (present / legible)

Check the screw connections

Outrigger

wire rope suspension, socket pin, counterweights

Ŷ

1

= Maximum test intervals, which could be significantly reduced depending on the

location of use and national regulations

.

)

Maintenance work activities for the traction hoists, rope stop and

wire ropes are described in the operating manual of the rope

winch.

Loading...

Loading...