61

Fryer Operation

GBF-50 Fryer

NOTE: The pump system is equipped with a pressure sensor. Should piping become clogged, or the

collection tank is full, excessive back‐pressure is detected and the pump will shutdown to prevent possible

damage. Should this occur, cease pump operation and have maintenance personnel inspect the system.

4.05 Removal of Waste Cooking Oil from Fryer - continued

1. Allow filter pan to sufficiently cool, then remove from fryer, disassemble and clean thoroughly. Refer to Section

5.03.

2. After waste oil has been removed, a Boil‐Out Procedure should be performed promptly. See Section 5.01, Boil‐

Out Procedure. It is recommended NOT to allow oil residue to remain in the vat for an extended period of time

... it will dry out, become difficult to clean, and can cause a build‐up which can negatively impact fryer

performance and food quality.

If postponing boil‐out is unavoidable, at a minimum, use absorbent paper wipes to clean as much waste oil

residue, as possible, from the vat & heating elements. Clean the filter pan and refill pot with fresh oil. Restart

fryer as described in Section 4.02, Cooking Procedures.

To perform a Boil‐Out on the unit, see Section 5.01, Boil‐Out Procedure.

To shut down unit, see Section 4.06, Normal Shut‐Down.

Completing the Oil Removal/Disposal Process:

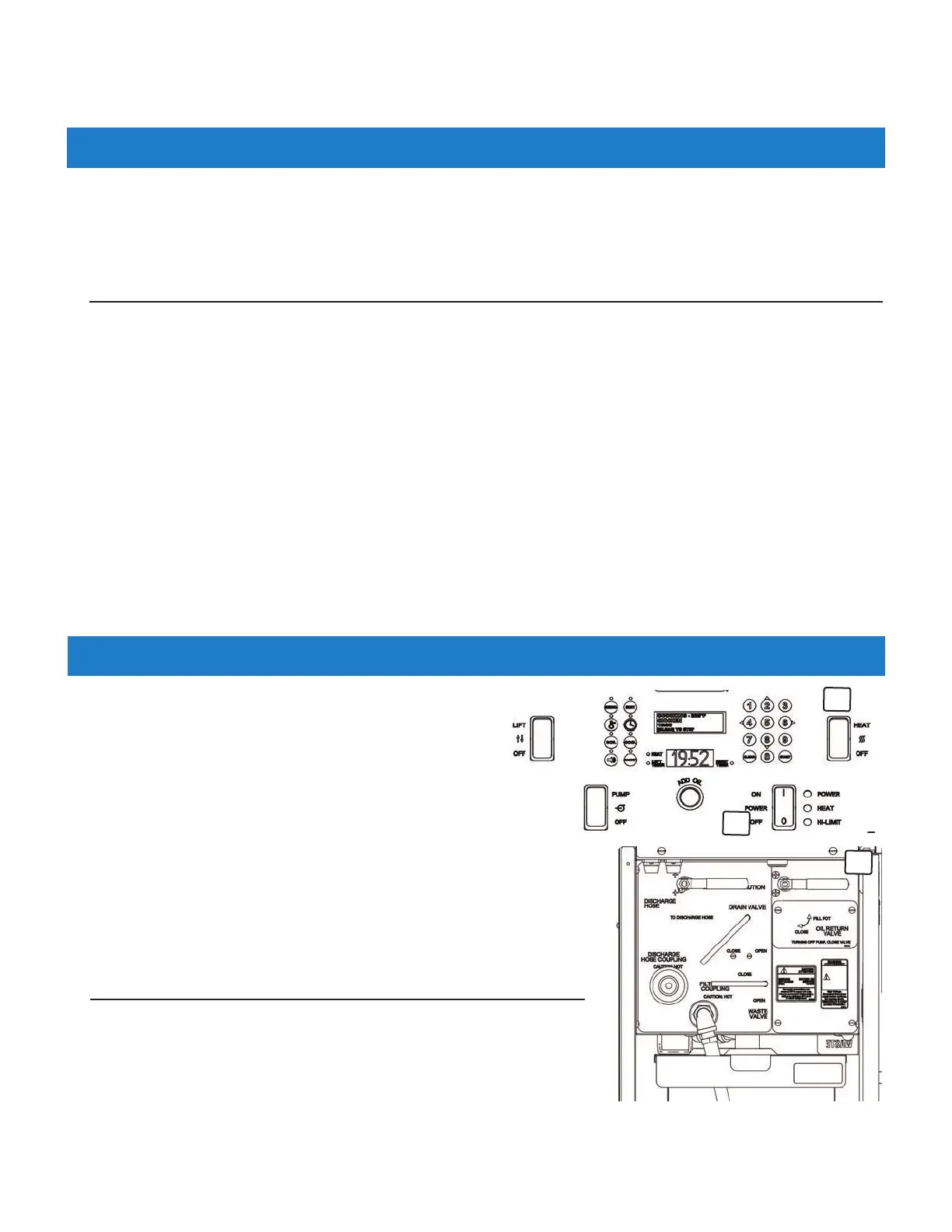

4.06 Fryer Shut-Down

1. Place Heat Switch(es) ① in [OFF].

2. Place Power Switch(es) ② in [OFF] position.

3. Verify that the Oil Return Valve(s) ③ is in the [CLOSE]

position (all units of banked system). Failure to do this

can allow oil to siphon back from vat to the filter pan.

On a banked systems this could result in overflow of the

filter pan overnight, and also create a low oil fire hazard at start‐up the

next day.

All units of a banked system require separate shutdown.

1

2

3

Emergency Shut‐Down:

In case of emergency, disconnect supply power from the appliance at the

building’s main electrical panel, and/or follow all standard emergency

procedures prescribed by your specific Standard Operating Procedures.

Loading...

Loading...