Do you have a question about the GRAPHTEC LABERLROBO DLC1000 and is the answer not in the manual?

Lists and describes included accessories, dedicated accessories, and consumable items.

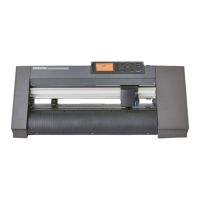

Identifies and explains the function of each part of the machine's main unit and cutter unit.

Instructions for connecting the machine to a computer via USB or network interfaces.

Details cutter plunger types, nomenclature, and adjusting the blade length for optimal cuts.

Step-by-step guide for mounting and dismounting the cutter plunger (tool) onto the machine.

Explains the functions of control panel lamps and keys for operating the machine.

Provides instructions on safely turning the machine on.

Covers procedures for setting up various label materials, including types and loading.

Instructions on how to correctly align push rollers for proper media handling.

Guides on setting and using laminate material with the machine.

Details the process and precautions for using the cross cutter function.

Explains how to set up and operate the slitter for cutting label material.

Describes the purpose of the COND/TEST key for accessing cutting conditions and performing tests.

Guides on choosing and setting tool conditions like tool type, offset, force, and speed.

Explains the precise method for adjusting blade length to achieve optimal cutting results.

Provides instructions on performing test cuts to verify and optimize cutting parameters.

Introduces the driver software, its compatibility, and system requirements.

Details how to use the driver software for printing label data from applications.

Shows the initial screen displayed when the machine is powered on.

Explains status displays during cutting, copying, or media feeding operations.

Lists and describes the main menu items and their purposes.

Guides on performing copy operations and setting the ending feed for labels.

Explains how to use the sensor to locate the start mark for accurate cutting alignment.

Details how to access and modify various machine operational settings.

Covers setting the number of registration marks for axis or inclination adjustments.

Explains how to modify the registration mark sensing speed for better detection.

Guides on adjusting the sensor offset for precise registration mark positioning.

Describes how to use the paper restraint feature for improved media sensing.

Details enabling/disabling bar code reading for print data identification.

Explains how to activate the frame cut feature for cutting outer edges of labels.

Guides on setting the offset force for initial blade control and cutting pressure.

Covers correcting discrepancies in line lengths and media feeding direction.

Describes switching display units between millimeters and inches.

Explains programming USB and Network (LAN) interfaces for machine connectivity.

Details required settings for LAN connection: DHCP, IP address, subnet mask, gateway.

Solutions for common operational problems like no power or machine not responding.

Lists machine error codes, their causes, and troubleshooting steps.

Explains warning messages related to media handling, winding, and setup errors.

Detailed technical specifications including loadable media, dimensions, and power requirements.

Lists available supplies, consumable items, optional accessories, and recommended kits.

Provides detailed diagrams with measurements of the machine for installation.