ES0609 rev D 4/09

9

Tool Number – Enter the tool to be used.

Work Offset – Enter the work offset to be used.

Z Start Pt – Enter the Z axis starting point.

Inside Dia. – Enter the current diameter of the work piece. Manually measure the diameter.

Dia. to Cut – Enter the nished diameter.

Z Dimension – Enter the Z axis dimension of the part from the Z start point.

Depth of Cut – Enter the depth of cut for each pass of the stock removal.

Feed Per Rev – Enter the feed per revolution.

MAX RPM – Enter the maximum spindle turning speed.

SFM – Enter the Surface Feed per Minute.

Fillet Radii – Enter the corner llet radii or enter ‘0’ for none.

Tool Nose – Enter the tool nose radius.

Advanced Users: In the full CNC mode this is a G71 command.

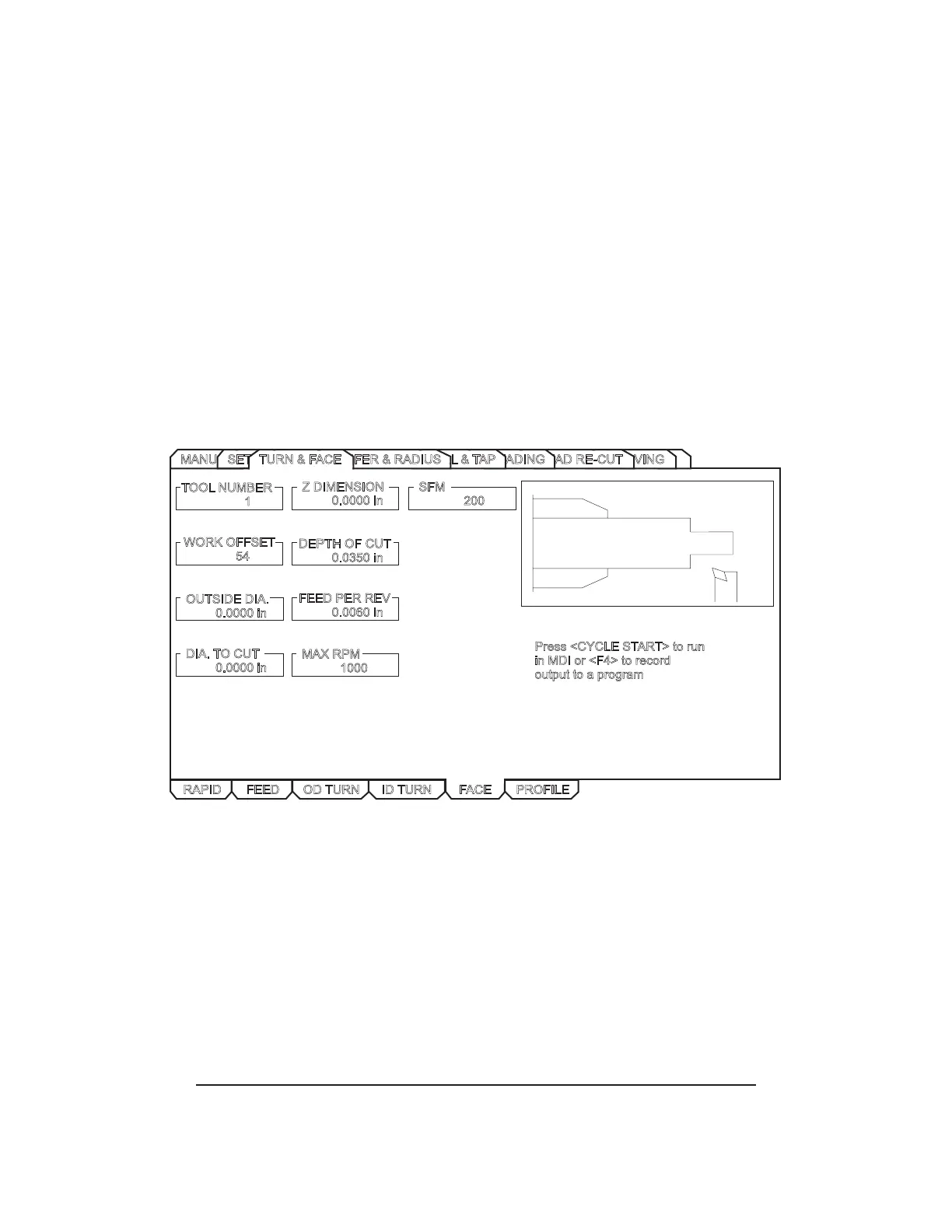

Turn & Face - Face

This mode is for making an end facing cut.

RAPID FEED OD TURN FACEID TURN PROFILE

Press <CYCLE START> to run

in MDI or <F4> to record

output toaprogram

TOOL NUMBER

1

WORK OFFSET

54

OUTSIDE DIA.

0.0000 in

DIA. TO CUT

0.0000 in

Z DIMENSION

DEPTH OF CUT

0.0350 in

FEED PER REV

0.0060 in

MAX RPM

1000

SFM

200

0.0000 in

GROOVINGTHREAD RE-CUTTHREADINGDRILL &TAPCHAMFER&RADIUSMANUALSETUPTURN&FACE

Tool Number – Enter the tool to be used.

Work Offset – Enter the work offset to be used.

Outside Dia. – Enter the current diameter of the work piece. Manually measure the diameter.

Dia. to Cut – Enter the nished diameter.

Z Dimension – Enter the Z axis dimension of the part from the Z start point.

Depth of Cut – Enter the depth of cut for each pass of the stock removal.

Feed per Rev – Enter the feed per revolution. This is the distance the tool will move for each revolution of the

spindle.

MAX RPM – Enter the maximum spindle turning speed.

SFM – Enter the Surface Feed per Minute.

Advanced Users: In the full CNC mode this is a G72 command.

NOTE: Entering a negative value for “Dia to Cut” causes the tool to pass spindle center

and machine the entire face of the part; Do Not enter a value larger than -.100”.

Loading...

Loading...