ES0609 rev D 4/09

29

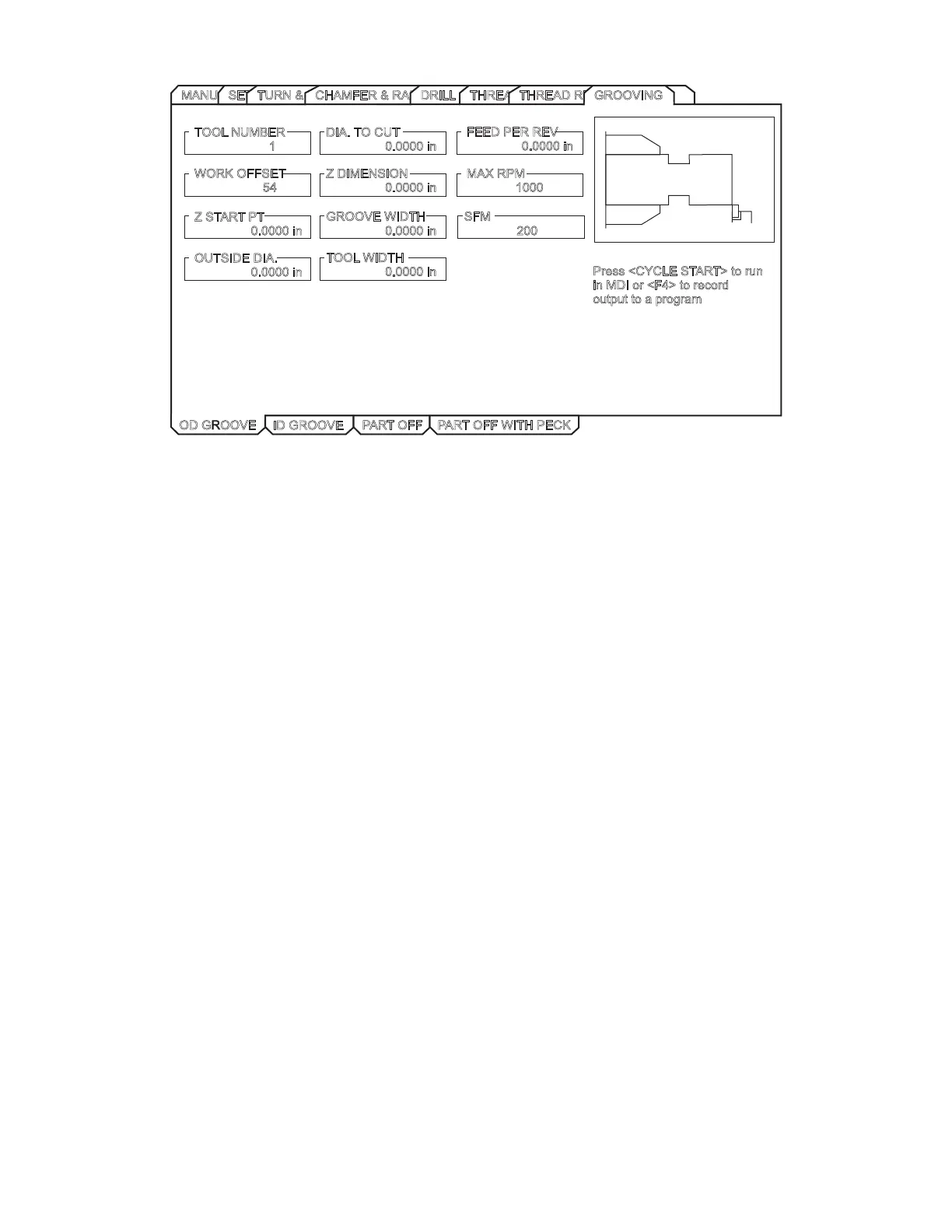

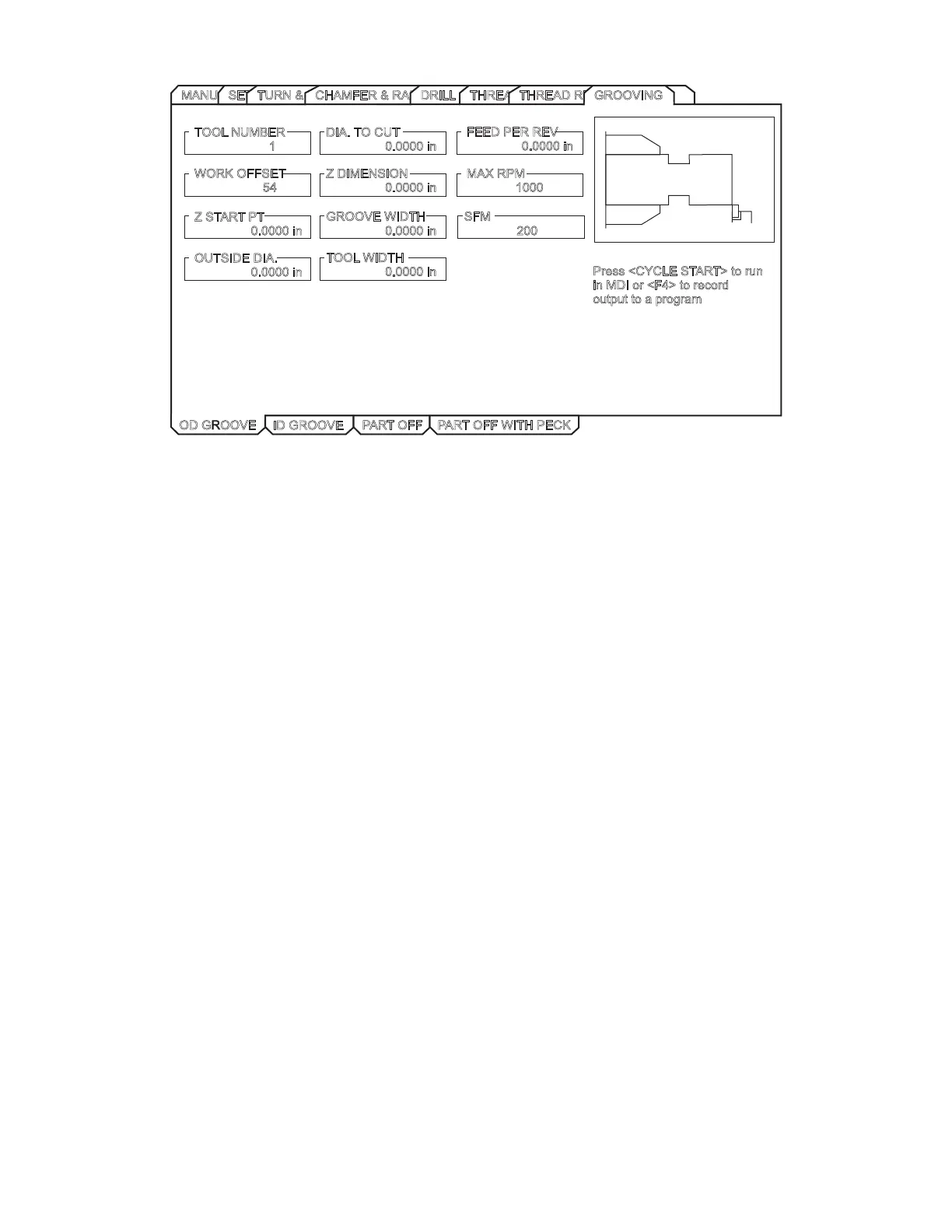

MANUALSETUPTURN&FACE

Press <CYCLE START> to run

in MDI or <F4> to record

output toaprogram

CHAMFER&RADIUSDRILL &TAPTHREADING

TOOL NUMBER

1

WORK OFFSET

54

ZSTART PT

0.0000 in

OUTSIDE DIA.

0.0000 in

OD GROOVE

ID GROOVE

PART OFF PART OFF WITH PECK

DIA. TO CUT

0.0000 in

0.0000 in

0.0000 in

TOOL WIDTH

0.0000 in

MAX RPM

1000

Z DIMENSION

GROOVE WIDTH

FEED PER REV

0.0000 in

200

SFM

THREAD RE-CUTGROOVING

Tool Number – Enter the tool to be used.

Work Offset – Enter the work offset to be used.

Z Start PT – Enter the Z axis starting point.

Outside Dia – Enter the current diameter of the work piece. Manually measure the diameter.

Dia to Cut (Diameter to Cut) – Enter the nished diameter.

Z Dimension – Enter the Z-axis dimension of the groove. Entered value must be positive.

Groove Width – Enter the nished width of the groove. Entered value must be positive.

Tool Width – Enter the actual width of the tool.

Feed per Rev – Enter the feed per revolution.

MAX RPM – Enter the maximum spindle turning speed.

SFM – Enter the Surface Feed per Minute.

Advanced Users: Additional Settings may need to be modied to create the required groove. These setting

numbers are: 22, 28, 72, 73, 86. See the denitions of the setting in the Operator’s Manual.

In the full CNC mode this is a G75 command.

Grooving Mode - ID Groove

This mode is for an outside diameter groove.

Loading...

Loading...