ES0666 rev D 09/09

4

to o l Se t u p

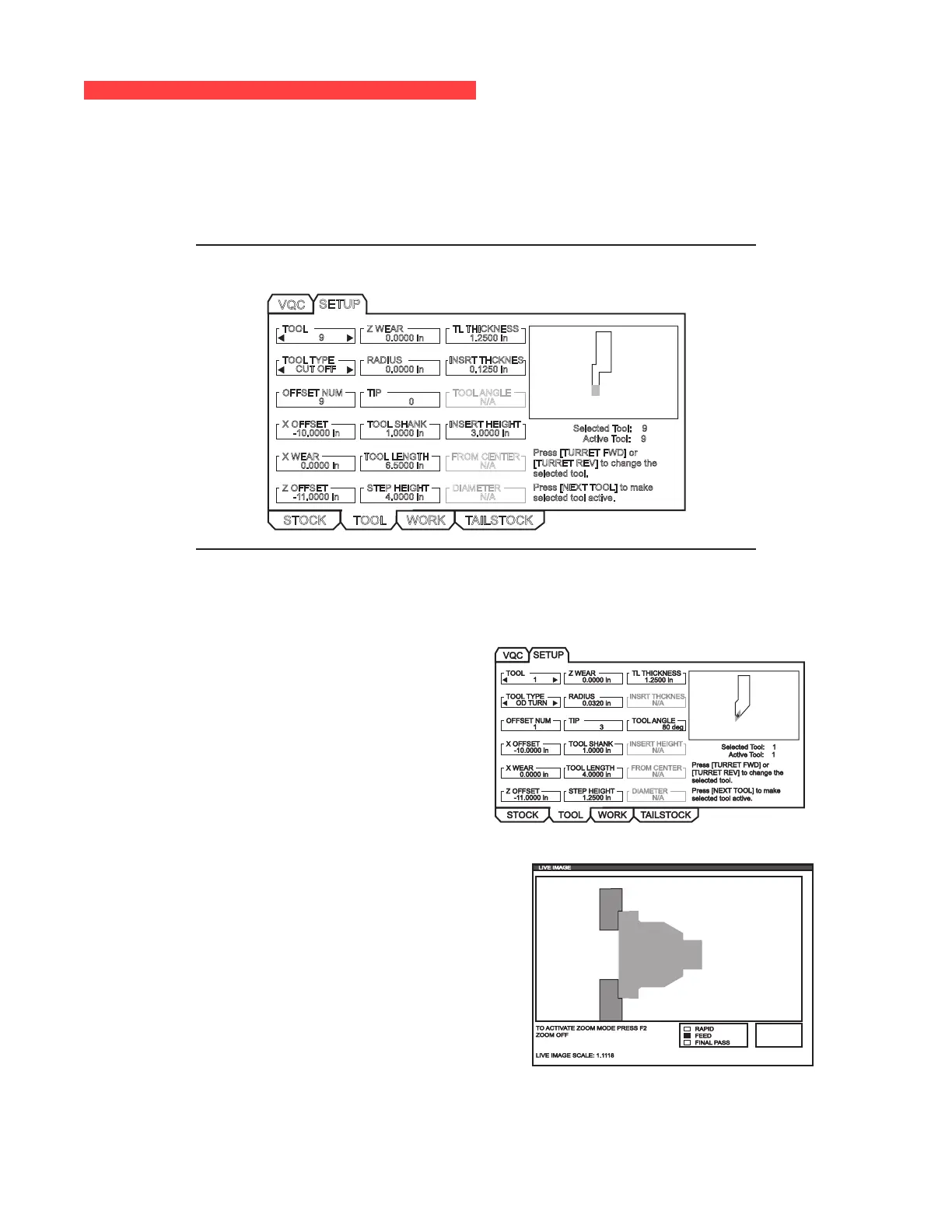

Tool data is stored in offsets in the IPS tabs. Live Image uses this information to draw and simulate the tool in

the cut. Required dimensions can be found in a tooling supplier’s catalog or by measuring the tool.

1. From the stock setup tab, press CANCEL, select the TOOL tab and press ENTER.

2. Select the tool number, type and enter the specic parameters required for that tool (i.e., offset number,

length, thickness, shank size, etc.).

NOTE: Setup parameter entry boxes are grayed out if they do not apply to the selected

tool.

TOOL

9

TOOL TYPE

CUT OFF

OFFSET NUM

X OFFSET

-10.0000 in

Z WEAR

RADIUS

TIP

0

TOOL SHANK

1.0000 in

TL THICKNESS

INSRT THCKNES

TOOL ANGLE

N/A

INSERT HEIGHT

3.0000 in

0.0000 in

VQC

SETUP

Selected Tool: 9

Active Tool: 9

STOCK TOOL WORK

X WEAR

0.0000 in

Z OFFSET

-11.0000 in

TOOL LENGTH

6.5000 in

STEP HEIGHT

4.0000 in

FROM CENTER

DIAMETER

1.2500 in

0.0000 in 0.1250 in

9

N/A

N/A

Press [TURRET FWD] or

[TURRET REV] to change the

selected tool.

Press [NEXT TOOL] to make

selected tool active.

TAILSTOCK

NOTE: Tool offset data may be entered for up to 50 tools.

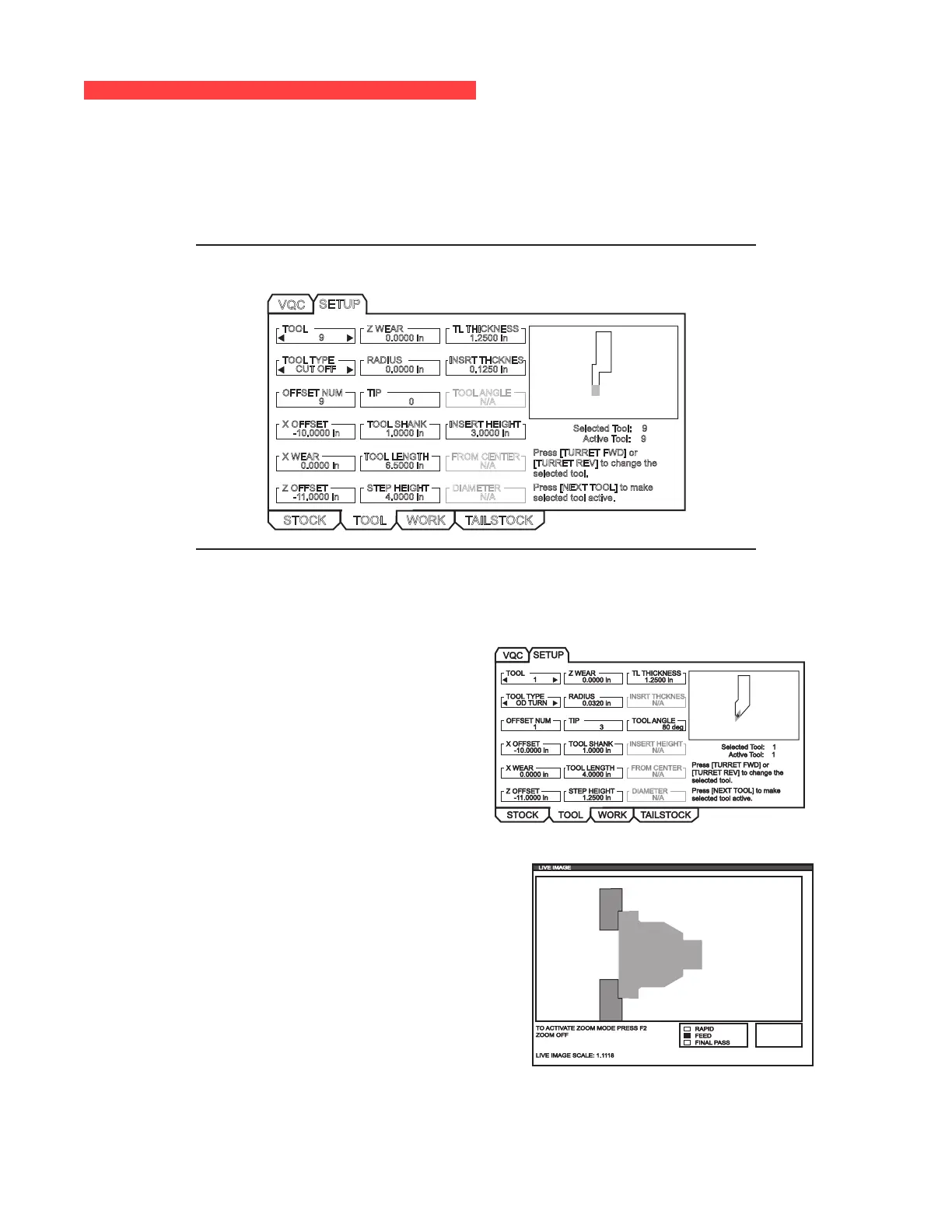

The following section shows part of a lathe program that is cutting a piece of stock. The program is shown to

the left, while the appropriate tool settings are shown to the right.

O01000 ;

;

;

;

T101 ;

G54 ;

G50 S4000

G96 S950 M03 ;

M08 ;

G00 X6.8 ;

Z0.15 ;

G71 P80103 Q80203 D0.25 U0.02 W0.005 F0.025 ;

N80103 ;

G00 G40 X2.

G01 X2.75 Z0. ;

G01 X3. Z-0.125 ;

G01 X3. Z-1.5 ;

G01 X4.5608 Z-2.0304 ;

G03 X5. Z-2.5606 R0.25 ;

G01 X5. Z-3.75 ;

G02 X5.5 Z-4. R0.25 ;

G01 X6.6 Z-4. ;

N80203 G01 G40 X6.8 Z-4. ;

G00 X6.8 Z0.15 ;

M09 ;

M01 ;

G28 ;

M30 ;

T101 Settings

Part Worked from T101 Settings

Loading...

Loading...