ES0609 rev D 4/09

21

Feed Per Rev – Enter feed per revolution (distance the tool will move for each revolution of the spindle).

MAX RPM – Enter the spindle RPM.

Dwell – Enter dwell time (time, in seconds, that the tool pauses at the bottom of the hole to clear chips).

Advanced Users: In the full CNC mode this is a G82 command.

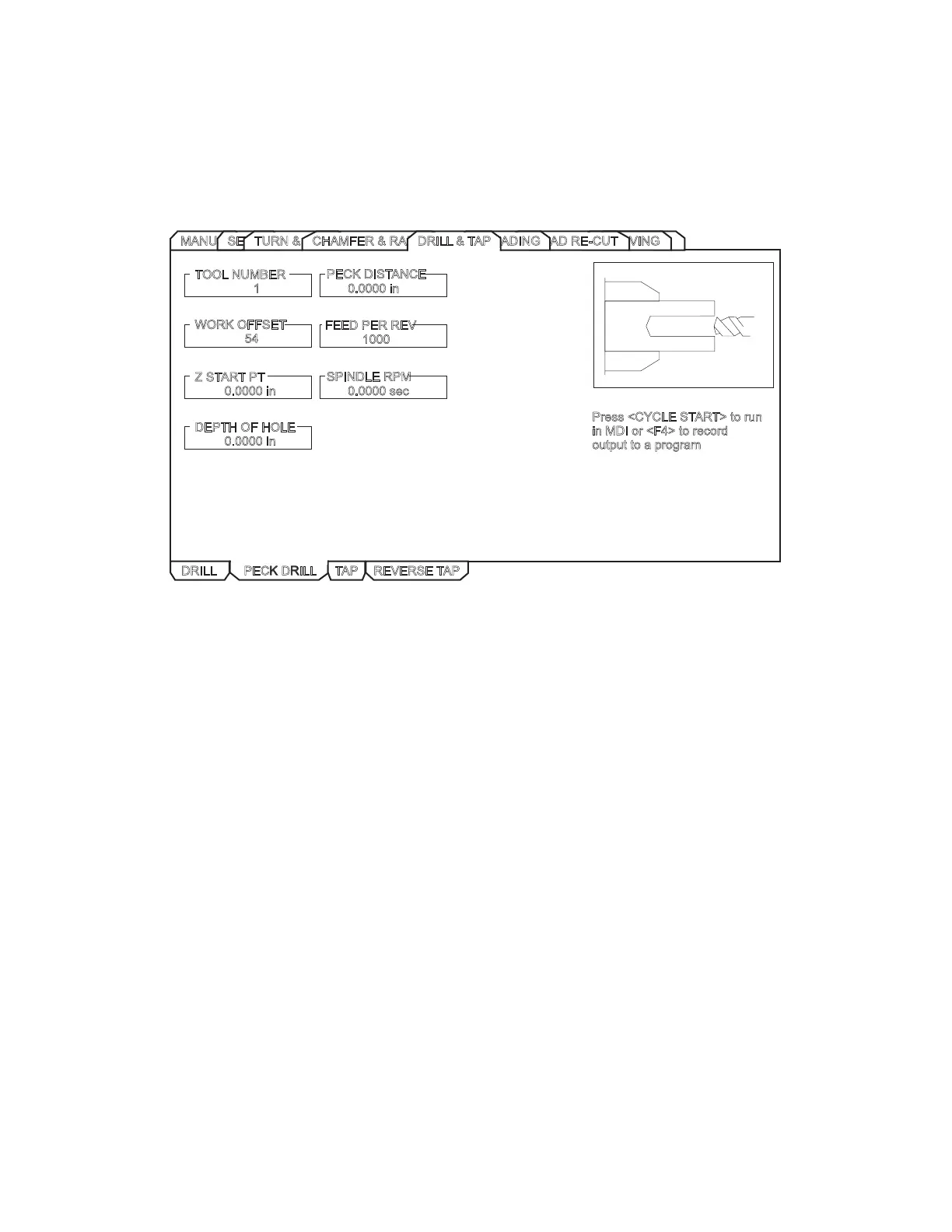

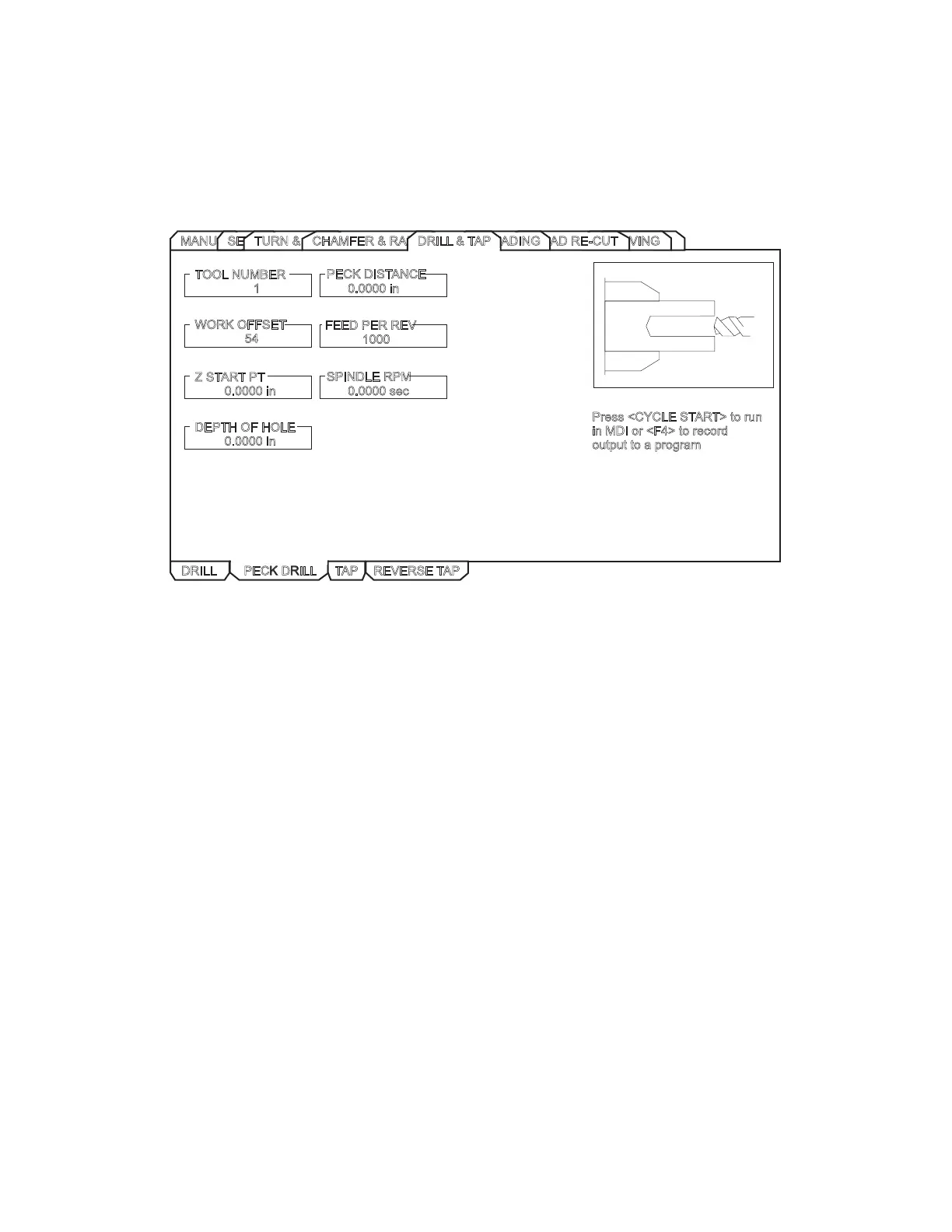

Drill & Tap - Peck Drill

This mode is for drilling in a pecking motion in order to remove the chip build up while drilling the hole.

Press <CYCLE START> to run

in MDI or <F4> to record

output toaprogram

DRILL PECK DRILL

TAP REVERSE TAP

TOOL NUMBER

1

WORK OFFSET

54

ZSTART PT

0.0000 in

DEPTH OF HOLE

0.0000 in

0.0000 in

0.0000 sec

PECK DISTANCE

SPINDLE RPM

FEED PER REV

1000

GROOVINGTHREAD RE-CUTTHREADINGMANUALSETUPTURN&FACECHAMFER&RADIUSDRILL &TAP

Tool Number – Enter the tool to be used.

Work Offset – Enter the work offset to be used.

Z Start Pt – Enter the Z axis starting point.

Depth of Hole – Enter the depth to drill. Entered value must be positive.

Peck Distance – Enter the length of each ‘peck’ before retracting to clear chips. This is the distance the tool

will advance at each “peck”. This value cannot be negative.

Feed Per Rev – Enter feed per revolution (distance the tool will move for each revolution of the spindle).

Spindle RPM – Enter the spindle RPM. This is the commanded spindle speed.

Advanced Users: In the full CNC mode this is a G83 command.

Drill & Tap - Tap*

This mode is for cutting right hand threads using a tapping tool.

Loading...

Loading...