4 - Sprayer set-up

36

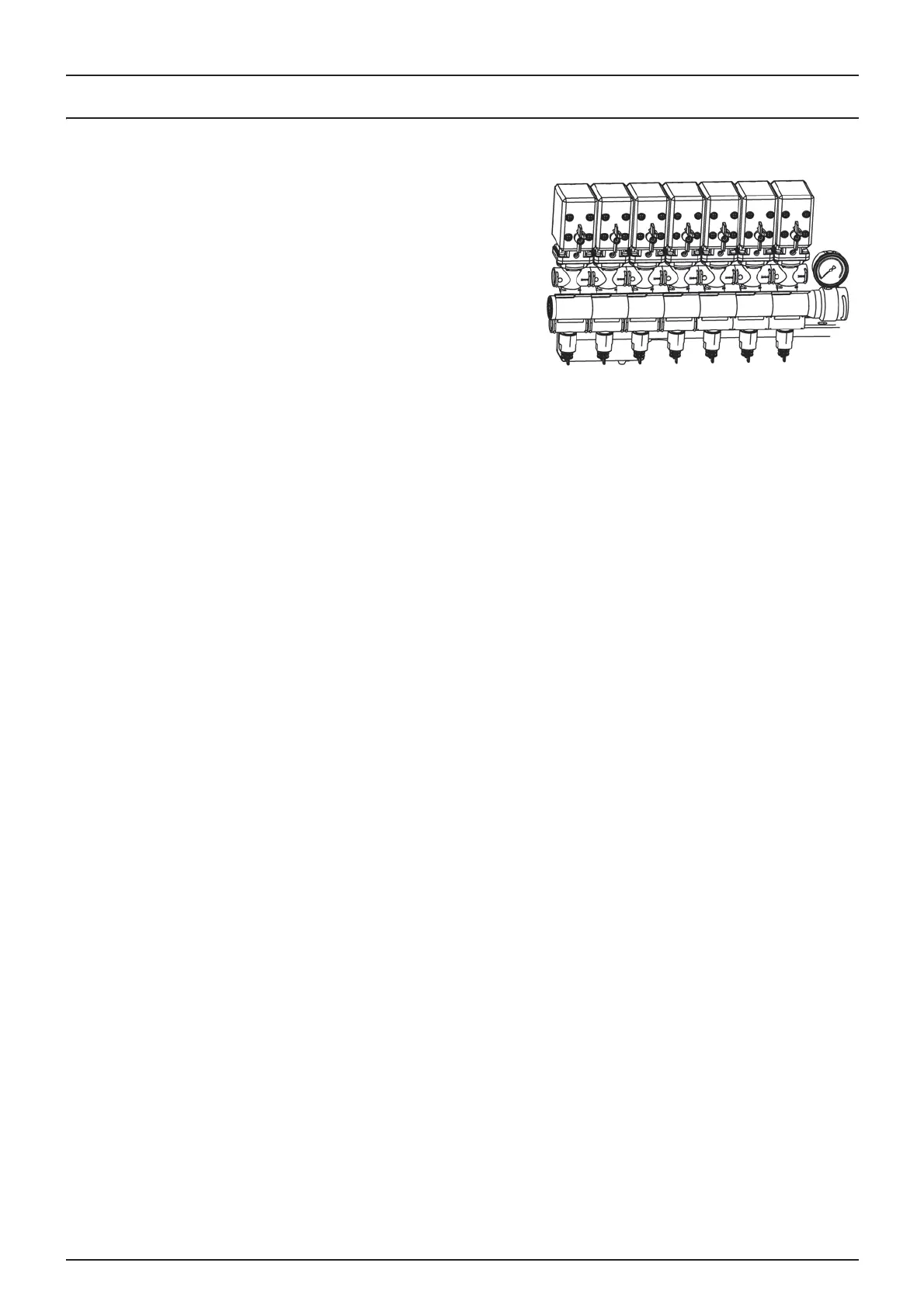

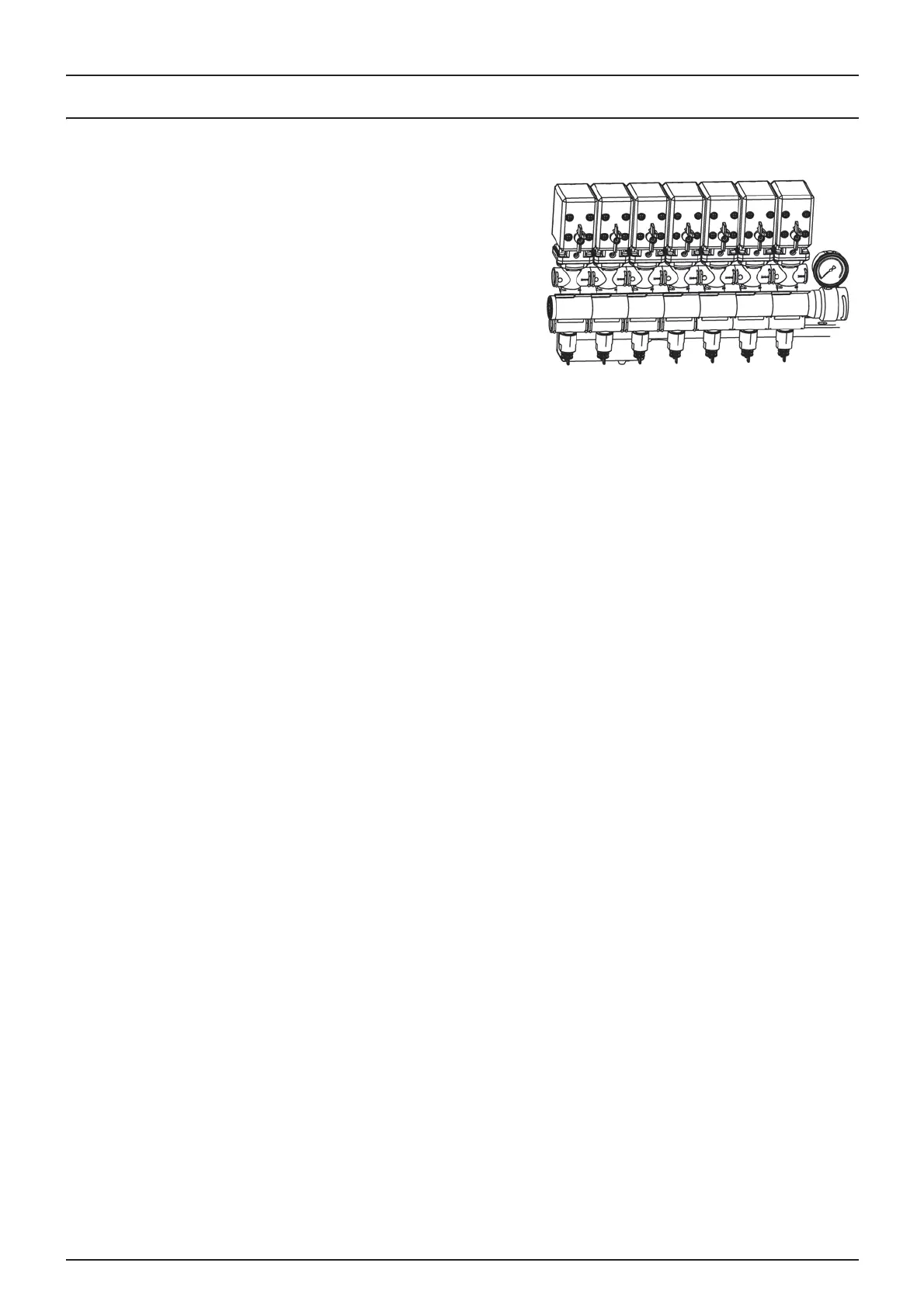

Spraying system

Use of electrical EVC adjustment

Before spraying, it is necessary to adjust the setting using clean water

(no agro-pharmaceutical products).

1. Select the appropriate nozzles for the treatment by turning the

Triplet nozzle holder. Check that all the nozzles are of the same

type and size. Refer to the "Application Techniques" manual.

2. Set the On/Off switch to On on the spraying control unit.

3. Set all the switches on the sections to ON on the spraying control

unit.

4. Lower the pressure regulation switch until the emergency lever on

the control valve stops turning (minimum pressure).

5. While stationary, rotate the PTO drive and with it the pump at the

planned speed. The PTO drive should rotate at between 300 and 600 rpm (pump 540 rpm) or between 650 and

1,100 rpm (pump 1,000 rpm).

6. Lift the pressure setting switch on the spraying control unit until the pressure gauge indicates the required pressure.

PRESSURE COMPENSATION SETTING:

7. Close the first section on the spraying control unit.

8. Turn the compensation screw until the pressure gauge indicates the required pressure again.

9. Open the section again.

10. Set the other sections one by one, using the same method.

IMPORTANT! A NEW PRESSURE COMPENSATION SETTING WILL BE NECESSARY IF:

1. YOU USE NOZZLES OF A DIFFERENT SIZE

2. THE FLOW THROUGH THE NOZZLES INCREASES DUE TO WEAR

Loading...

Loading...