5 - Operation

53

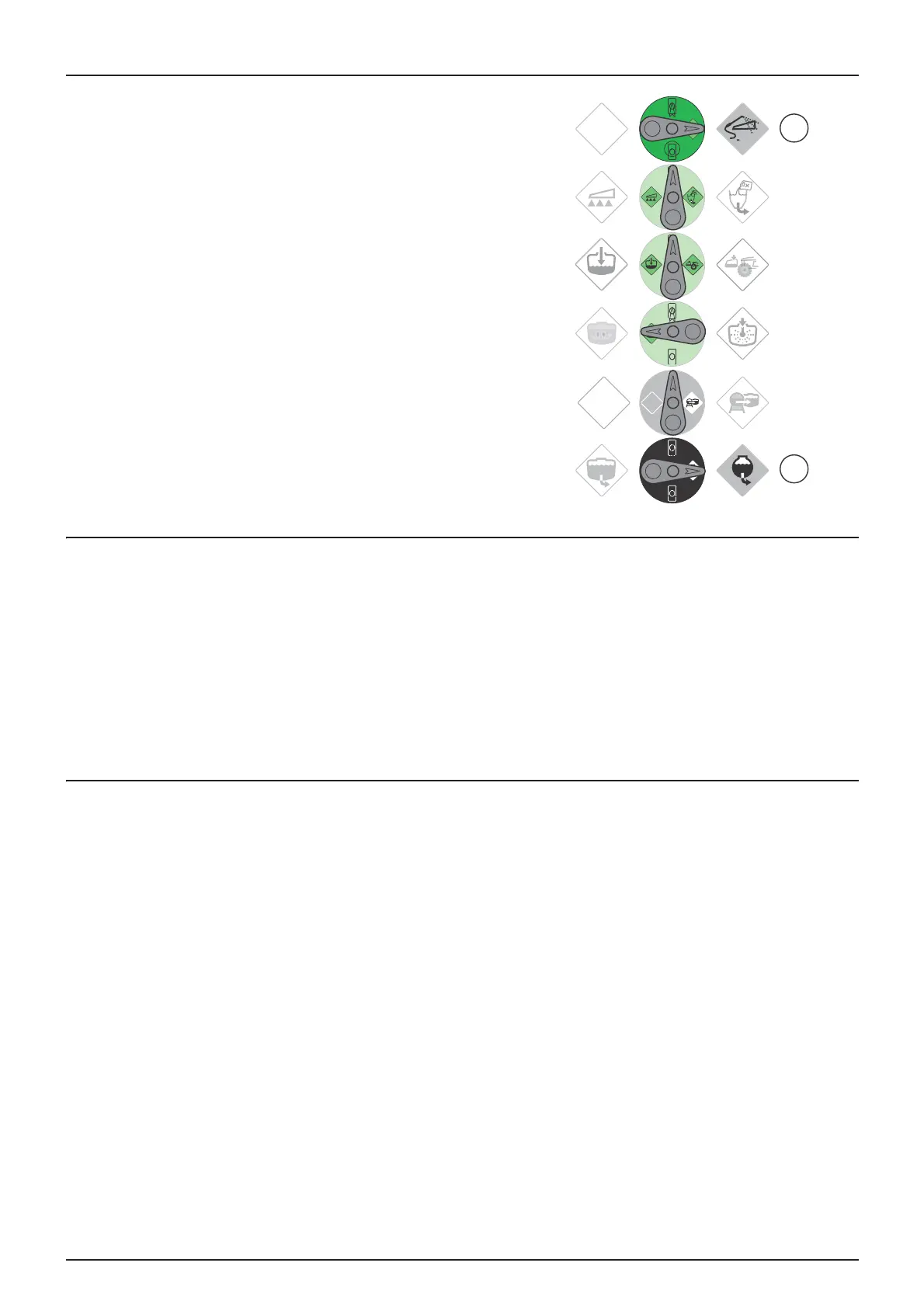

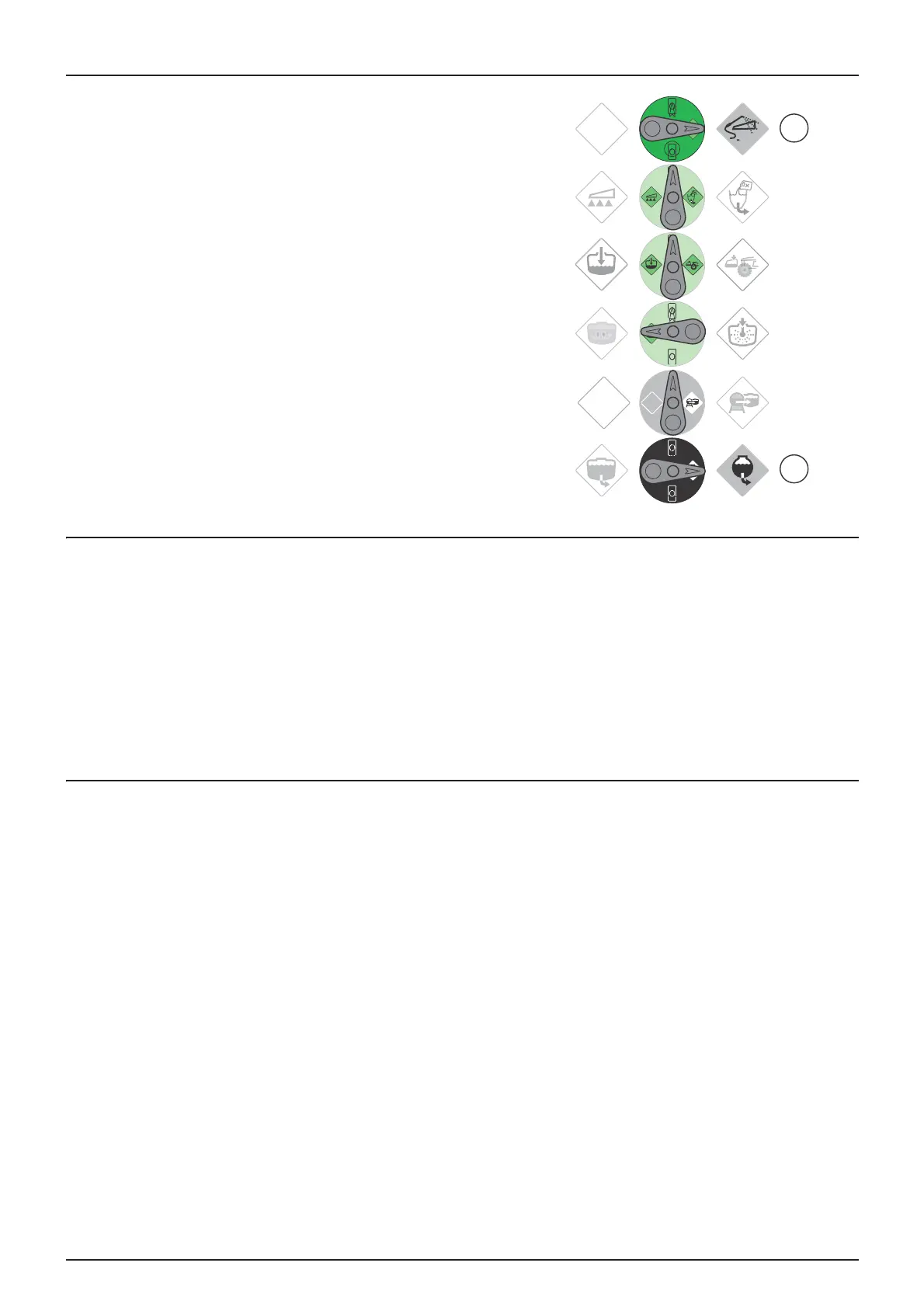

1. Turn the suction valve (1) to "Rinsing tank" and the pressure valve

(2) to "External washing gun".

2. Engage the spraying pump at idle and accelerate to obtain the

necessary pressure for washing the sprayer.

3. Squeeze the gun grip to clean the sprayer.

4. When the operation is complete, replace the gun in the position

provided.

Boom purge (optional)

If you have purge valves at the ends of the boom, the cleaning procedure is as follows:

1. Rinse twice as per the normal cleaning procedure.

2. Open the purge valves.

3. Carry out a third rinse as per the cleaning procedure.

4. Close the purge valves.

±

WARNING! To prevent any contamination, the purge valves must only be opened during the final stage of cleaning.

Dead volume

A certain quantity of mixture inevitably remains in the system. It cannot be spread on the crop since the pump will end up

sucking air into the tank.

The dead volume is defined as the quantity of liquid in the system when the first clear pressure drop shows on the gauge.

The bottom of the tank must immediately be diluted with ten times its volume of clean water and sprayed on the field just

treated while increasing the forward speed. The pump, hitch and chassis may also be rinsed with water from the rinsing tank.

But you need to be sure that the mix contained in the pipes has no variation in concentration. It is therefore preferable to

have an untreated field on which to spray the dead volume.

1

2

Loading...

Loading...