6 - Maintenance

63

Occasional maintenance

General information

The maintenance/replacement intervals for the following parts depend greatly on the conditions of use to which the

sprayer is subjected and it is therefore not possible to be precise.

Replacing pump valves and diaphragms

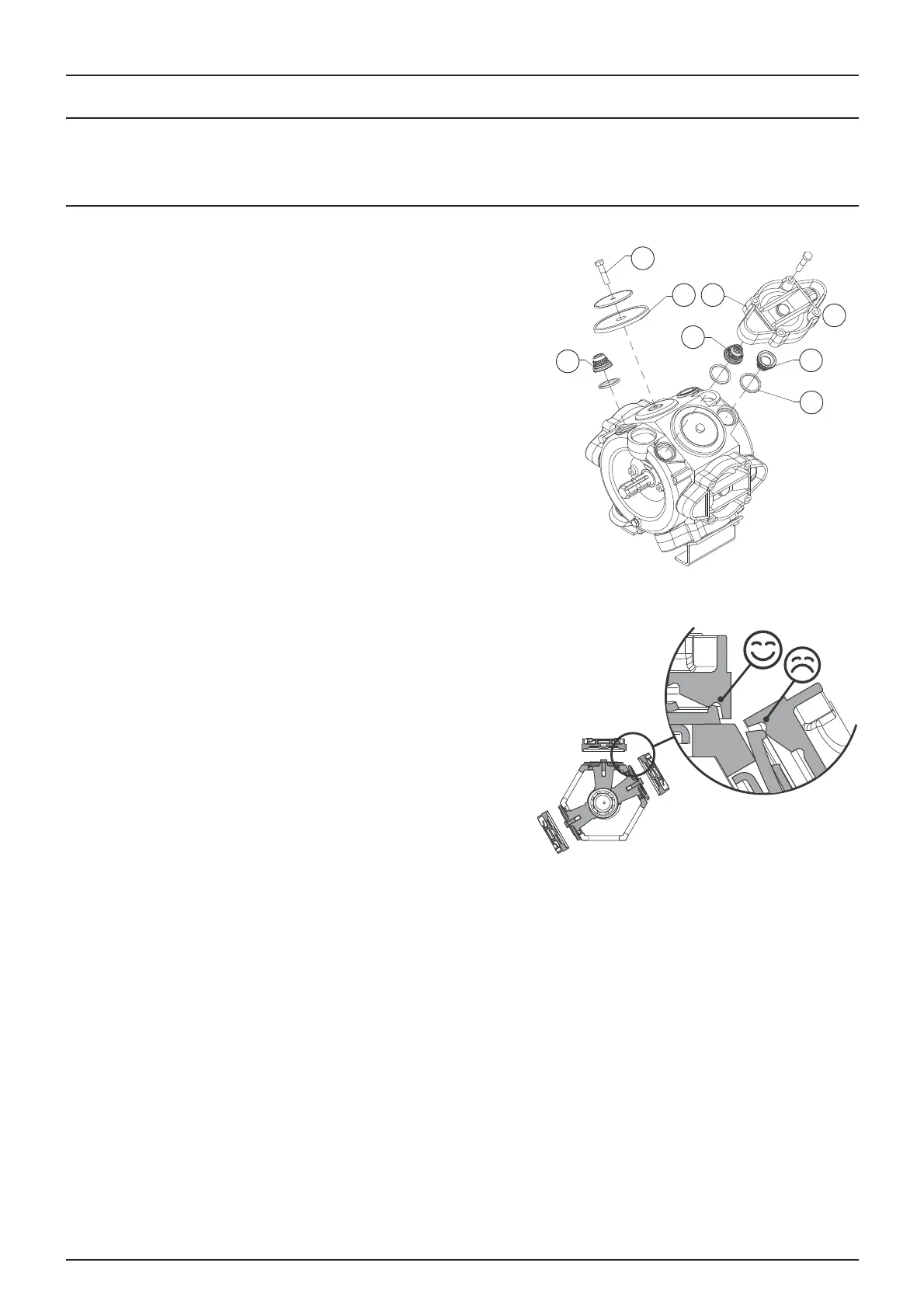

Pump model 363:

Repair sets for diaphragm pumps are available (valves, gaskets,

diaphragms, etc.). Check the pump model - the reference for the

HARDI EVRARD set is:

Model 363: part no. 75073700

Valves

Remove cover (1) to replace valves (2) - note their orientation for

re-fitting them correctly.

IMPORTANT! A special valve with a white mechanism (2A) must

be fitted to the two upper intakes. Position them as illustrated.

All the other valves have a black mechanism. It is recommended

that new gaskets (3) are used for re-assembly.

Diaphragms

Remove bolt (4). Diaphragm (5) is now accessible. If the crankshaft

housing is wet, dry it and then grease the pump well. Also check that the

drain hole under the pump is not blocked. Re-fit the parts, applying the

tightening torques below.

Tightening torques for 363 pumps :

Diaphragm bolt (4): 90 Nm/66.6 lb/ft

Diaphragm cover bolts: 90 Nm/66.6 lb/ft

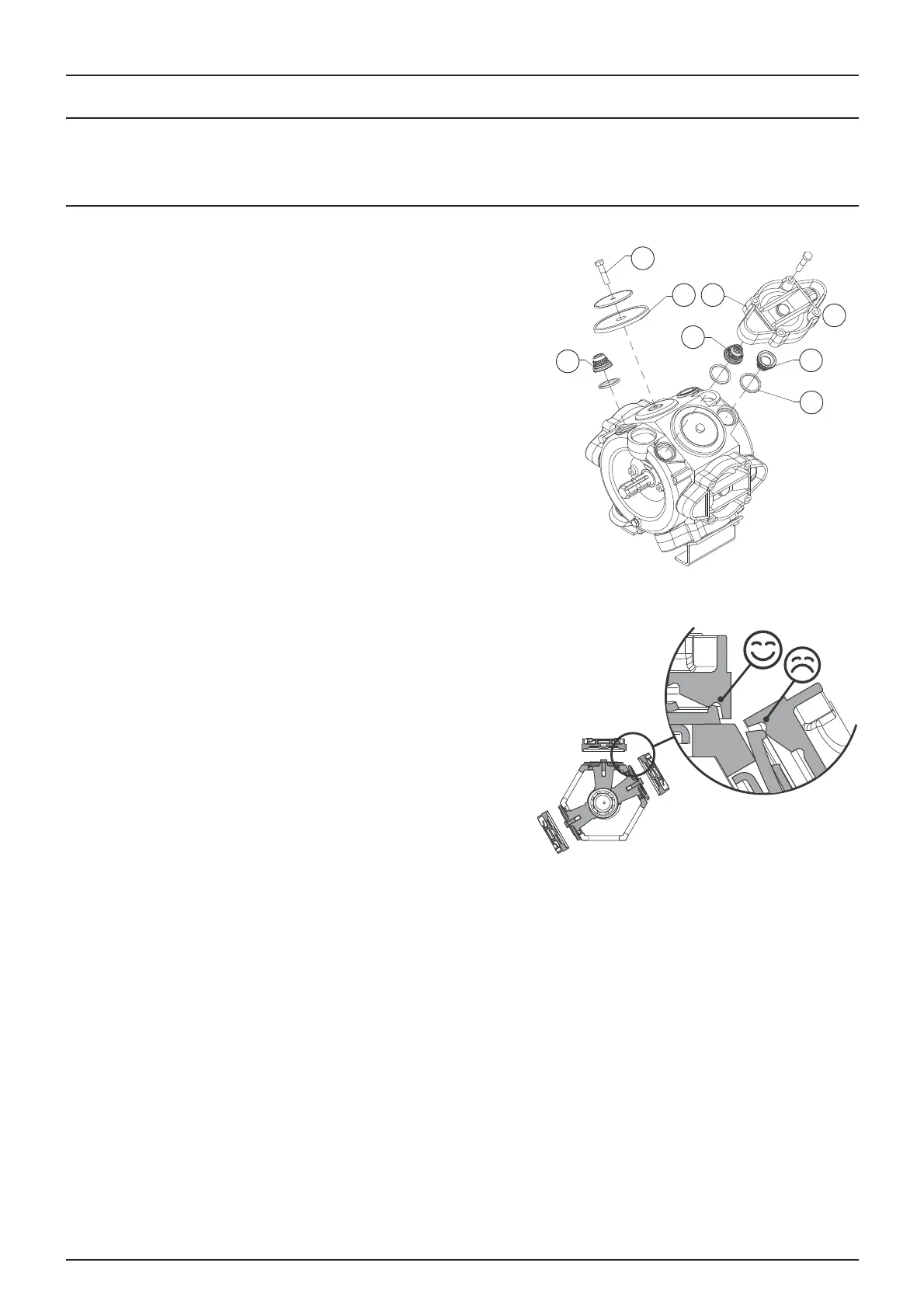

IMPORTANT! Before tightening the four bolts in the diaphragm cover (B), position the diaphragm between the middle

and the top in order to get a perfect seal between the pump housing and the diaphragm cover. Turn the crankshaft

if necessary.

Loading...

Loading...