6 - Maintenance

61

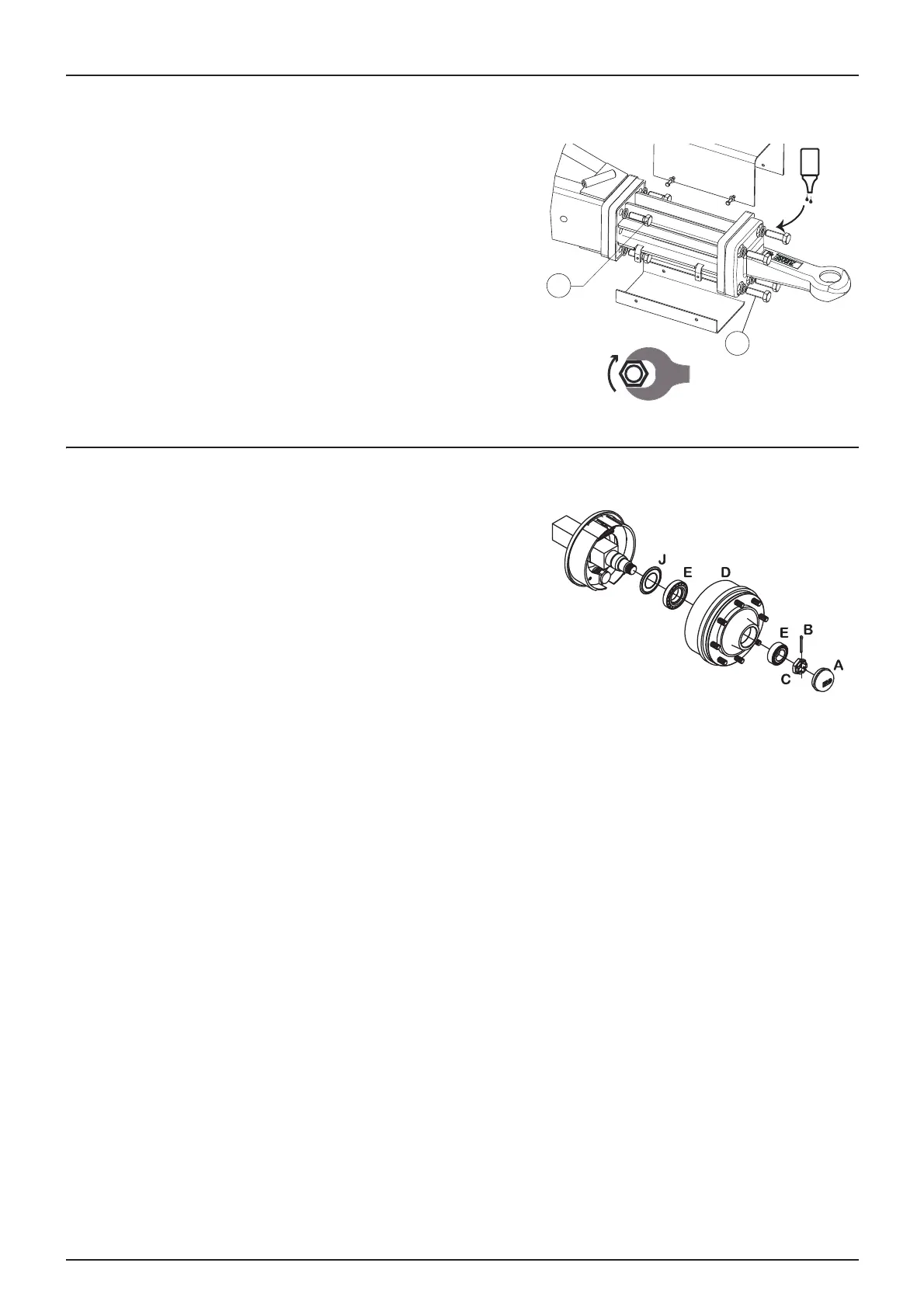

Every 1,000 hours - Hitch extension

Check the tightening of the fixing screws on the extension and hitch ring.

€

Apply the tightening torque indicated.

±

The screws are secured in place with High strength Thread-

locking fluid.

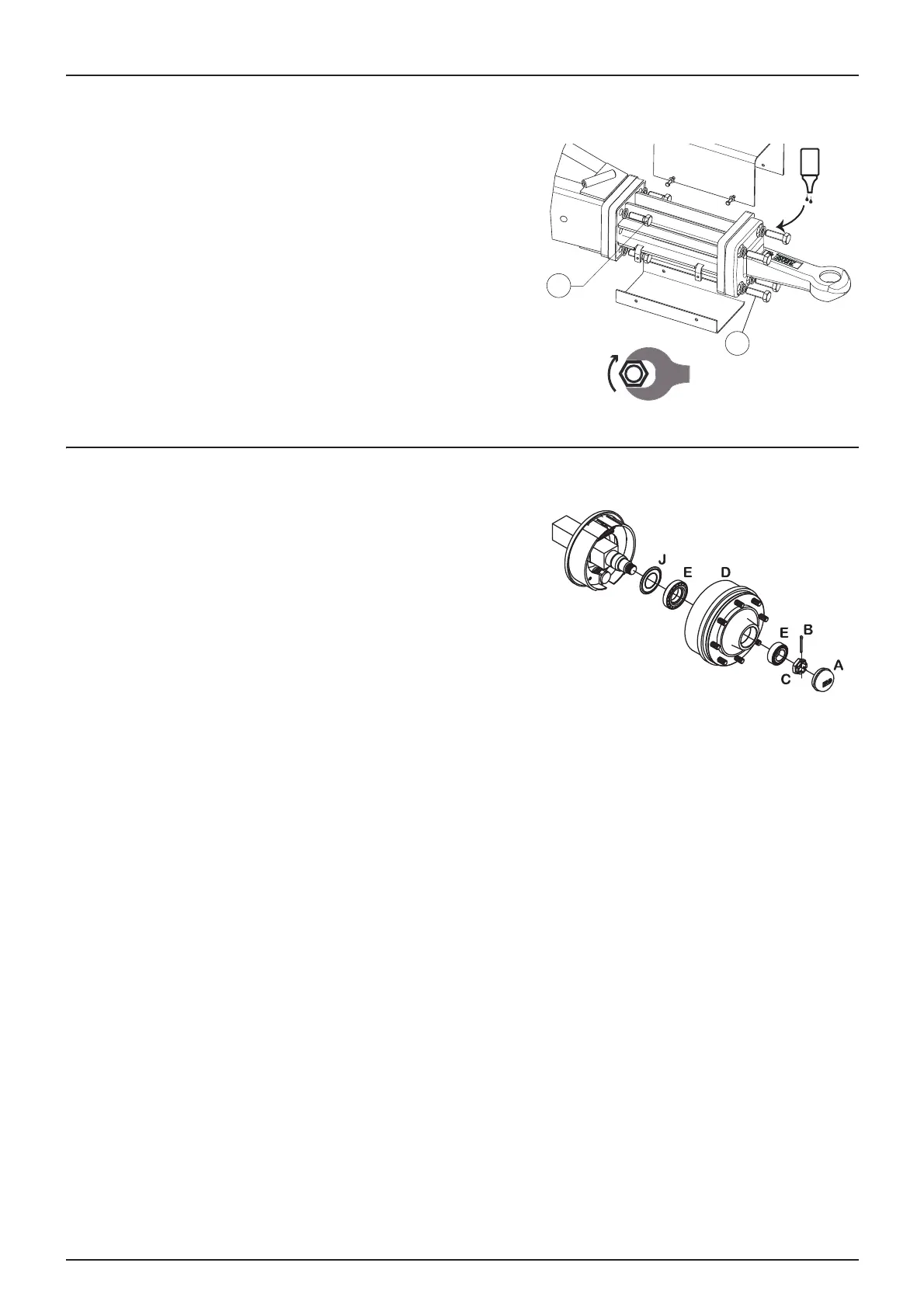

Every 1,000 hours - Wheel bearings and brakes

Check the condition of the bearings and wearing parts on brakes as

follows:

1. Put chocks in front of and behind the left wheel and raise the right

hand wheel.

2. Place stands under the axle.

3. Remove the wheel.

4. Undo the six Allen screws and remove hub cap (A), pin (B) and

shaft nut (C).

5. Remove the hub and the drum. Use a hub extractor if necessary.

6. Clean drum (D) with a vacuum cleaner or rinse with water.

7. Rinse the remaining parts of the axle frame with water and dry them.

8. Remove bearings (E), clean them with a degreasing product and dry them.

9. Check the diameter of the drum and thickness of the linings - replace them if they are worn.

Max. permitted wear on components:

Max. diameter of drum: 302mm (30.1998cm)

Min. thickness of linings: 2.0mm (2.00000mm)

€

DANGER! The dust released by brakes is harmful. Avoid inhaling brake dust. Wear a mask when doing maintenance

work on brakes. Do not clean brakes with an air compressor. Use a vacuum cleaner or rinse them with water to avoid

spreading dust.

±

WARNING! The minimum thickness indicated is the absolute minimum and must not be exceeded. Replace linings if

you think that they will not last until the next check.

±

WARNING! If you replace linings or drums, you must do so for both wheels.

IMPORTANT! If the drum has to be separated from the hub, a hydraulic press should be used to remove the studs from

the wheels.

±

WARNING! Avoid getting oil, grease or copper paste on linings and drums.

232 N.m

232 N.m

frein

filet

FORT

Loading...

Loading...