5 - Operation

50

Quick guide - Cleaning

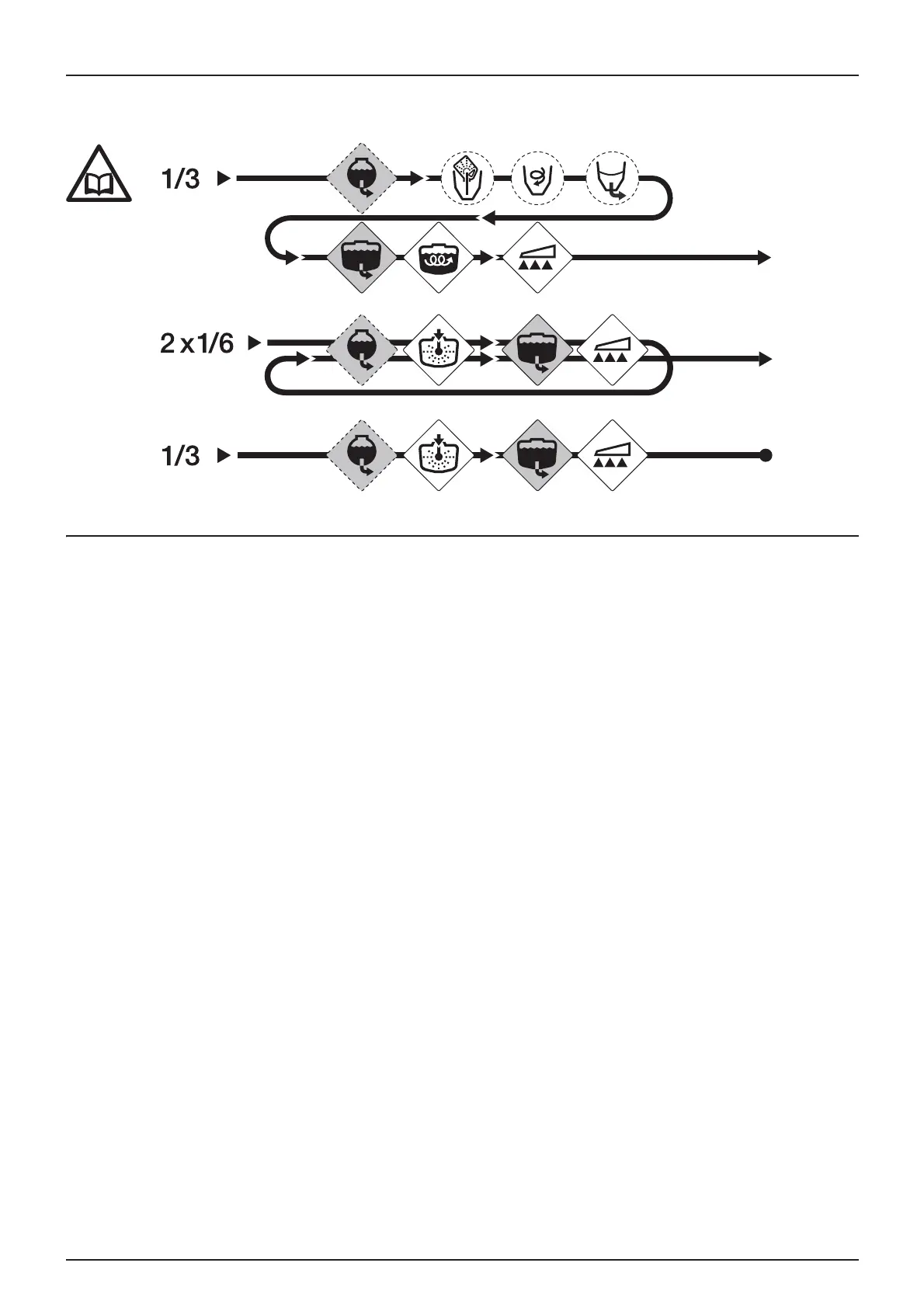

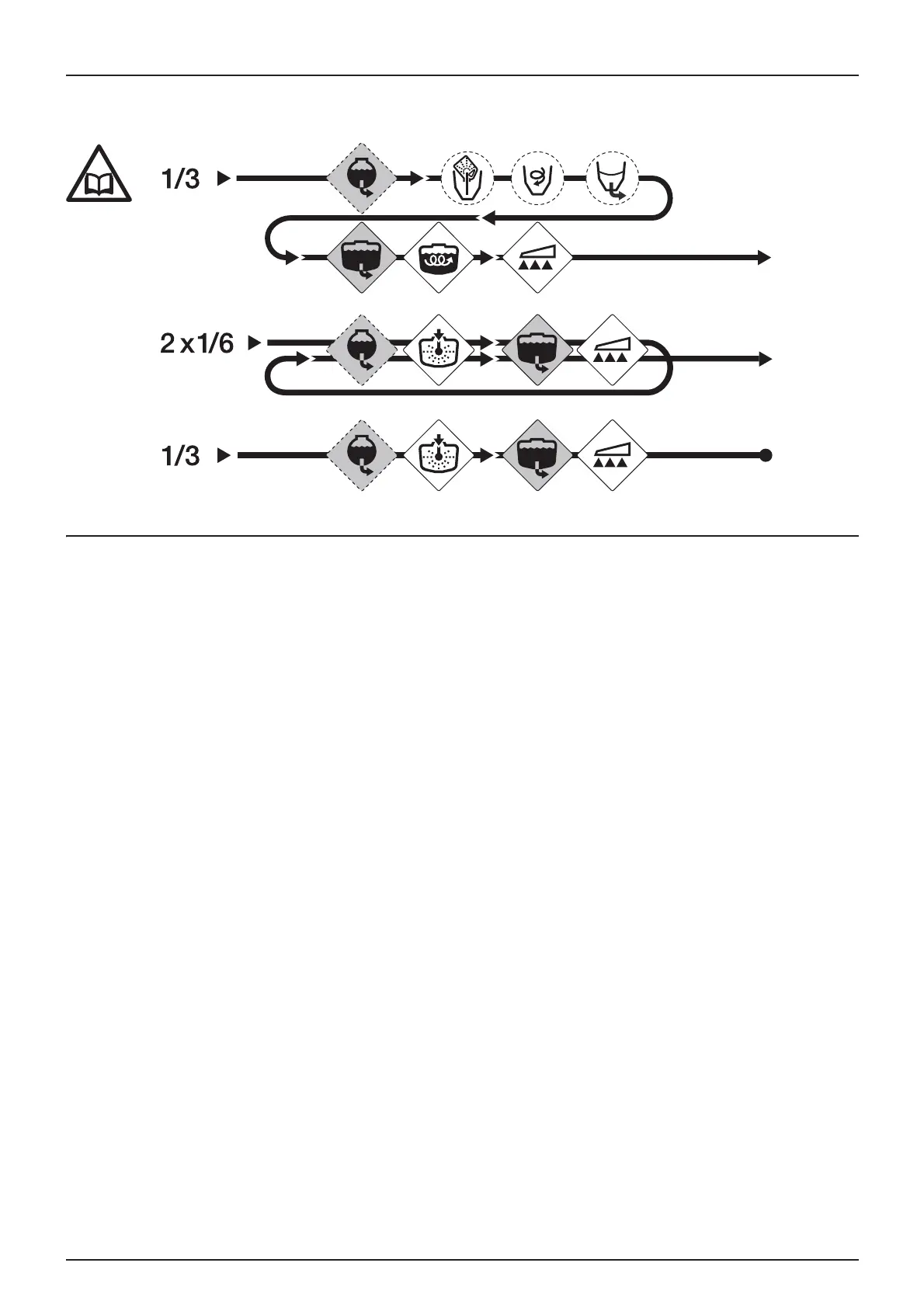

You will find below the correct position for the valves according to the desired operation.

Cleaning the tank and the spraying system

1. Dilute the mix remaining in the tank with at least ten times its volume of water and spray it on the field you have just

sprayed.

2. Wear appropriate protective clothing. Choose a detergent suitable for the cleaning and neutralising agents,

if necessary.

3. Rinse and clean the outside of the sprayer and the tractor. Use a detergent if necessary.

4. Remove the suction filter and strainer from the tank and clean them. Be careful not to damage the mesh. Replace the

suction filter. Replace the filters after the sprayer has been completely cleaned.

5. Switch on the pump and rinse the inside of the main tank. Do not forget the top of the tank. Rinse and operate all the

components that came into contact with the mix. Before opening the boom sections to spray rinsing water, ensure

that it will flow away safely, either onto the field just treated or into a retention tank.

6. Once the tank is empty, stop the pump and fill it again to at least one fifth of its capacity with clean water.

Some products require the tank to be filled completely. Add a detergent and/or a neutralising agent, for example,

sodium carbonate or triple ammonia. Special detergents for sprayers are recommended, since some of them also

contribute to greasing ball valves, etc.

7. Engage the pump and operate all the controls that allow the liquid to rinse all the components. Keep the boom

sections until last. Some detergents and neutralising agents are more effective if they remain in the tank for a while.

Check the instructions for their use.

8. Drain the tank and allow the pump to run. Rinse the inside of the tank with the pump still running.

9. Switch off the pump. If the product used has a tendency to block filters and nozzles, remove them and clean them

immediately.

10. Put all filters and nozzles back in place and put the sprayer away. If you notice that the solvents are particularly

aggressive, leave the tank lid off.

IMPORTANT! To spray the rest of the diluted mix on the field that has just been treated, it is advisable to increase the

forward speed (go at twice the speed, if possible) and reduce the pressure to 1.5 bar (20psi).

IMPORTANT! If a cleaning procedure is recommended by the manufacturer of the product used, follow it exactly.

IMPORTANT! If you clean the sprayer with a high-pressure sprayer, the equipment should be greased again all over.

Loading...

Loading...