130

7 - DELIVERY SYSTEM

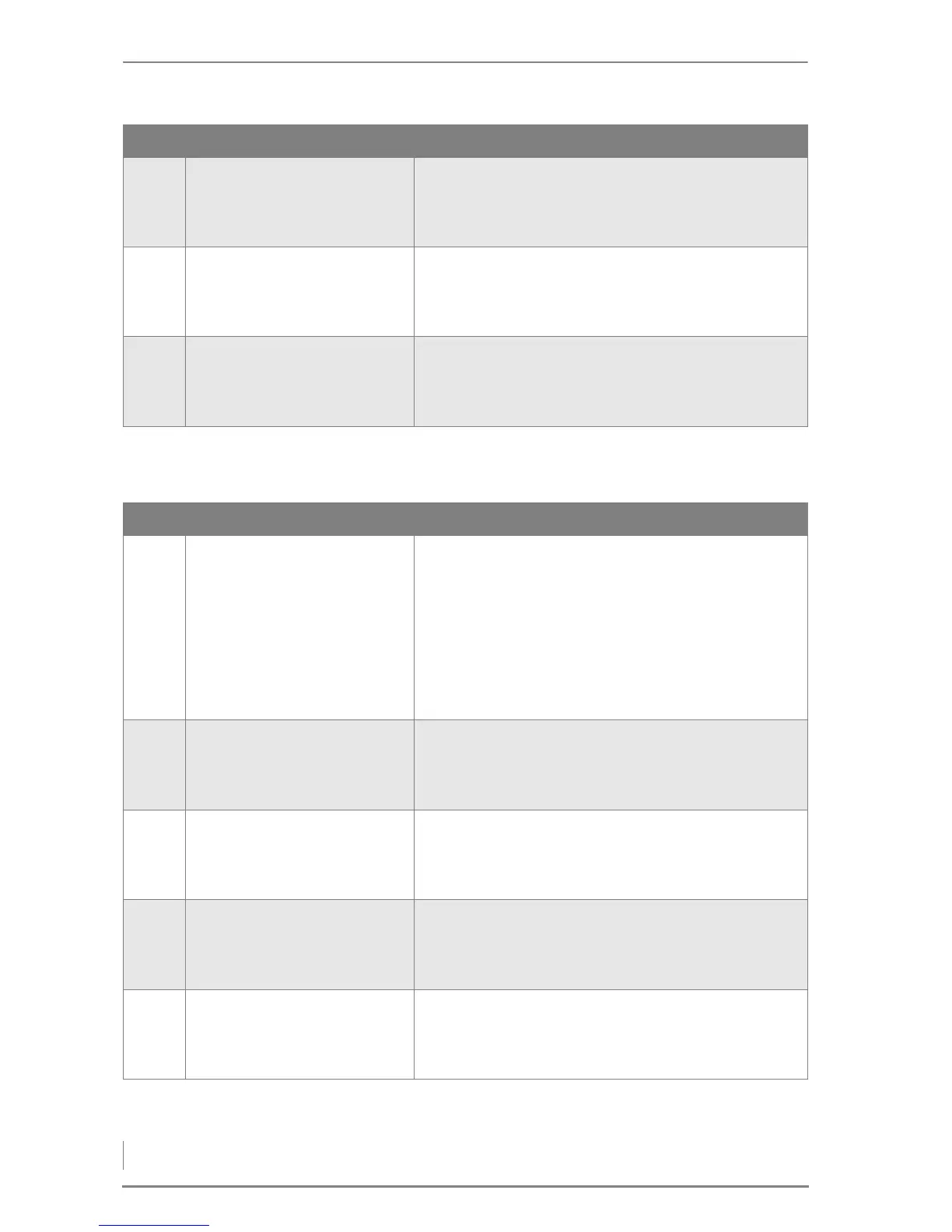

6-15 Cleaning

Monitor

cleaning system

( 6) 6m

• Monitoring of the cleaning system functions

The monitoring limit switch of the cleaning system must

trigger within this set time.

(0 - 180 m)

6-16 Cleaning

Empty ash box

after stoker runtime

( 0) 0h

• Emptying the ash box

The delivery auger runtime after which the message

“Empty ash box” is displayed. The setting of 0 switches off

the message function. (0 - 200 h)

6-17 Cleaning

Enable times

On 00:00 On 00:00

Off 24:00 Off 00:00

• Enable cleaning

Time block: Various enabling times can be programmed.

No. Display Description

Table 6/8 - System level / 6 - Cleaning

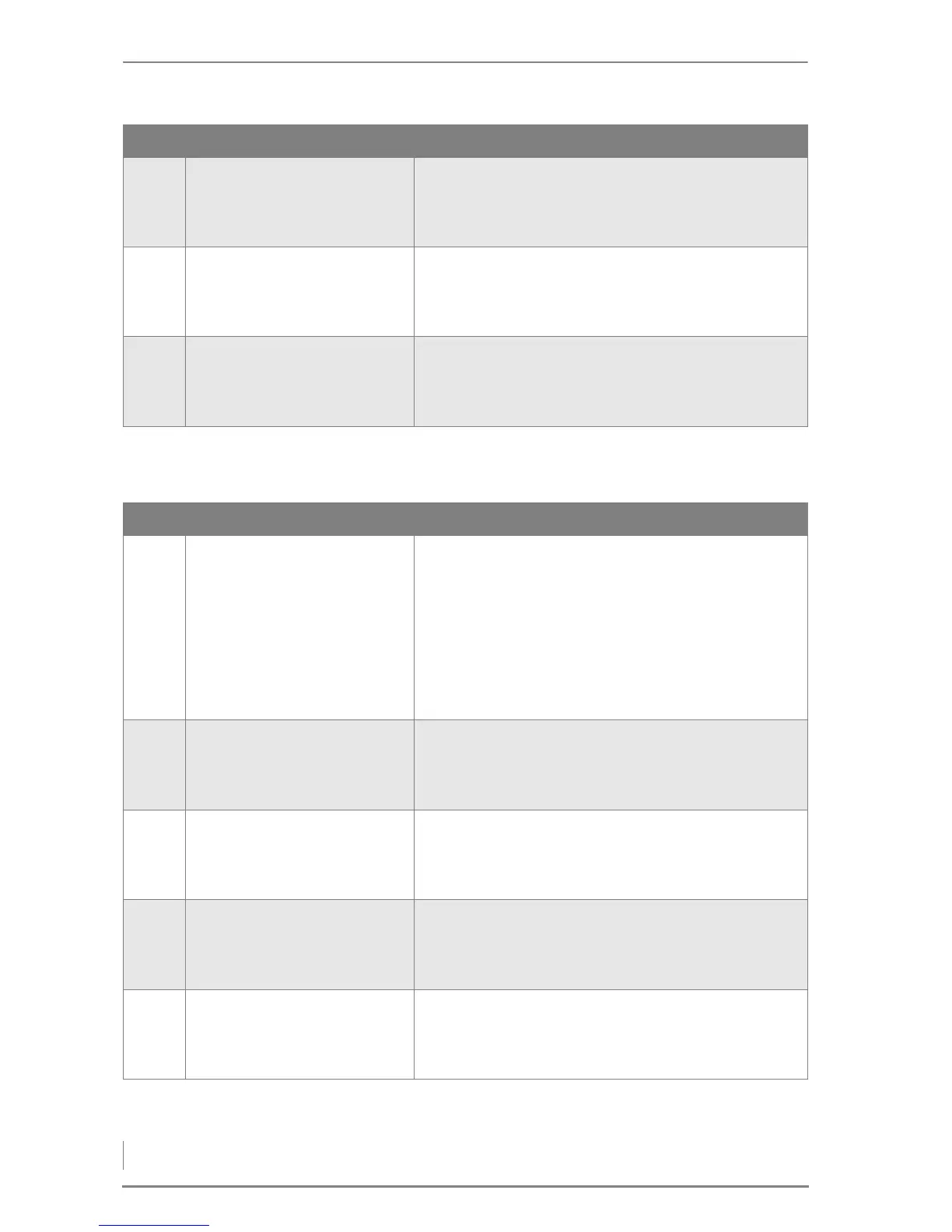

No. Display Description

7-01 Delivery type

Variant 1

Variant 2

Variant 3

Variant 4

Variant 5

• Type of delivery system

1: Flexi-blade or hinged arm delivery system

2: Delivery and conveyor auger

3: Delivery system, intermediate container and dosage

auger

4: Silo delivery system, intermediate container and

dosage auger

5: Pellet vacuum delivery system + pellet vacuum contai-

ner

7-02 Feeding system

Continuous running

Cycles

• Feeding system

Setting option for continuous running or clocked cycles

(together with the dosage auger).

7-03 Delivery system

Feeding system

reverse current

( 3.0) 3.0A

• Feeding system

After exceeding the set motor current, the motor reverses

up to three times. Then a fault message is issued. (0.1 -

10.0 A)

7-04 Delivery system

Response delay

Reversing

( 1) 1s

• Delivery system/feeding system

Delay time in the event of overcurrent at the drives to

reverse of the rotational direction.

(1 - 9 s)

7-05 Delivery system

Feeding system

reverse runtime

( 1) 1s

• Feeding system

Reverse running time when the set reverse current is

exceeded.

(0 - 3 s)

Table 6/9 - System level / 7 - Delivery system

Loading...

Loading...