CAUTION!

Mechanical hazard – risk of damage to the mold and hot runner. The nozzles and manifold

must be at room temperature (< 25 °C or < 77 °F) before the cavity plate is connected to the

hot runner. Severe damage to the nozzle and cavity plate sealing diameters could result if

the mold is still hot.

7. Slowly close the clamp to move the cavity plate into position. Make sure the wires in the wire

channels are not pinched between the plates while closing.

8. Lock out and tag the machine and controller (if equipped).

9. Remove all safety latch bars.

10. Install safety latch bars between the cavity plate and hot runner on both sides of the

assembly. A minimum of two safety latch bars are required.

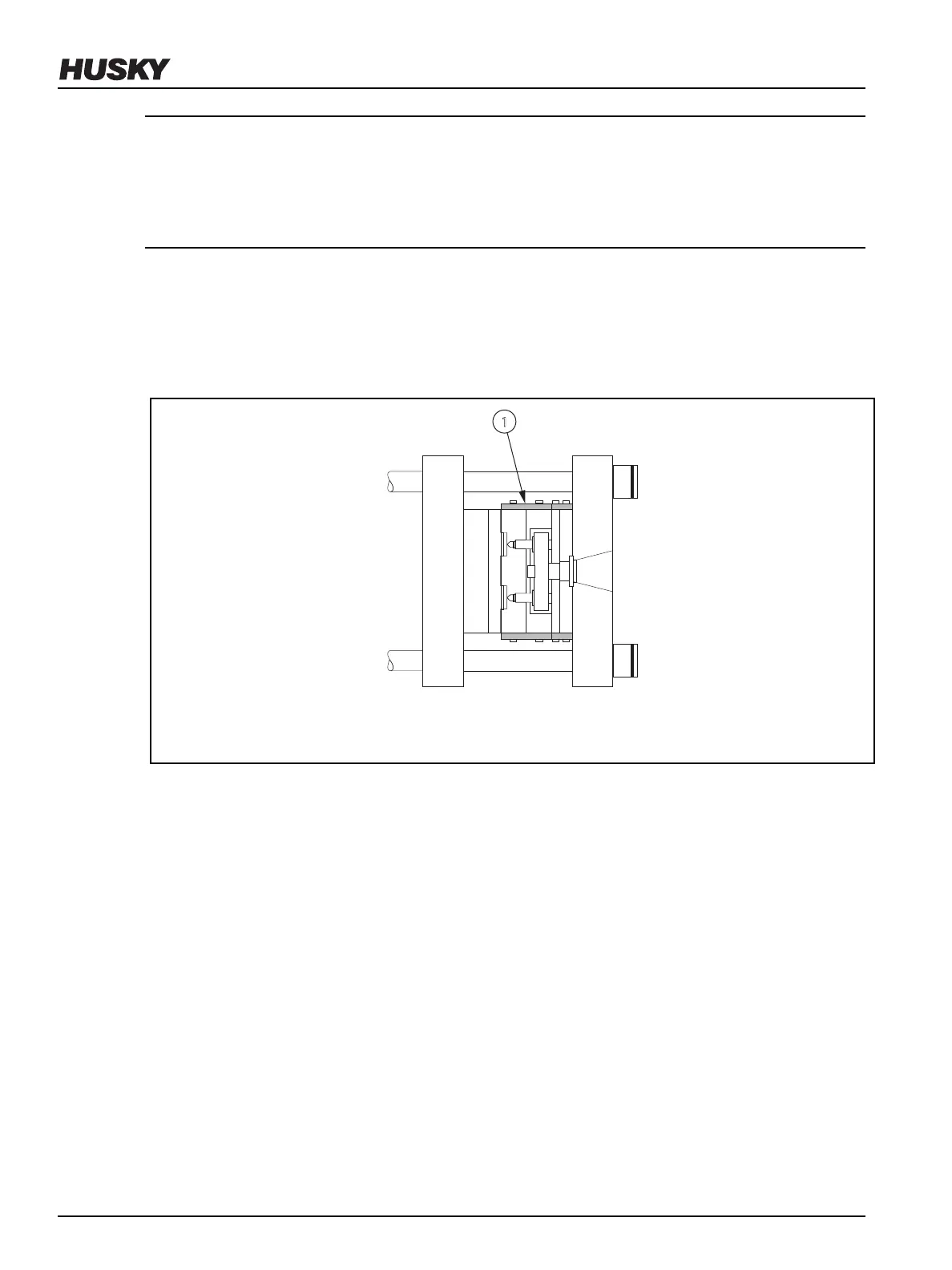

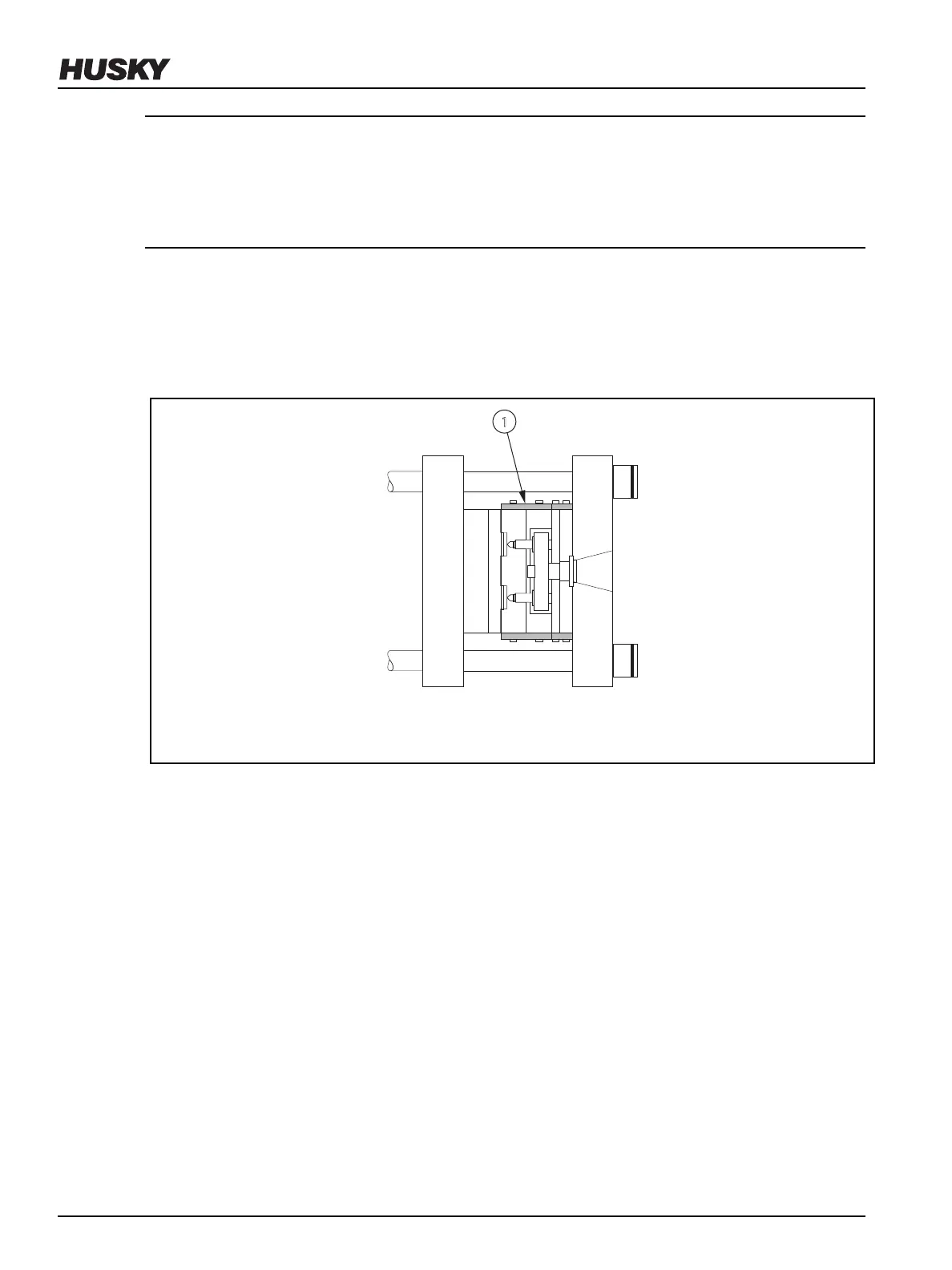

Figure 6-42: Latching the Cavity Plate to the Hot Runner (Overhead View)

1. Safety Latch Bar

11. Remove all locks and tags.

12. Reduce the clamp opening and closing speed.

13. Slowly open the clamp to move the cavity plate away from the core plate.

14. Lock out and tag the machine and controller (if equipped).

15. Install the screws that secure the cavity plate to the hot runner and torque them to the

specied value. Refer to the manufacturer’s documentation for torque requirements.

16. Remove all safety latch bars.

17. Check the electrical circuit with an ohmmeter to make sure no wires were damaged during

installation. Refer to the electrical schematic to identify each zone.

6.15

Inspecting and Cleaning Manifolds

To inspect and clean a manifold, do the following:

v 2.2 — March 2021 Unify Manifold System

104 Inspecting and Cleaning Manifolds

Loading...

Loading...