• Typical air pressure required is 5.52 to 8.27 bar (80 to 120 psi) , unless otherwise specied in

the mold manufacturer’s documentation.

NOTE:

For many pneumatic VG applications, air pressure of 7 bar (100 psi) may be sucient, while

some applications may require up to 12.5 bar (180 psi) for optimal and stable performance.

• Compressed air hoses must be large enough to permit adequate ow to the locations where

air is required.

• Compressed air used for mold actuators must be interlocked with the machine operator’s

gate, so opening the gate prevents any motion.

• Quick exhaust valves must be located close to the actuators they control, so the compressed

air in the mold will decompress rapidly and speed operation of the actuator.

• Lockout valves must be installed (according to ANSI Z244.1 or local regulations) to the air

supply for use when:

• Serving the mold

• Performing maintenance

• Installing and removing the mold

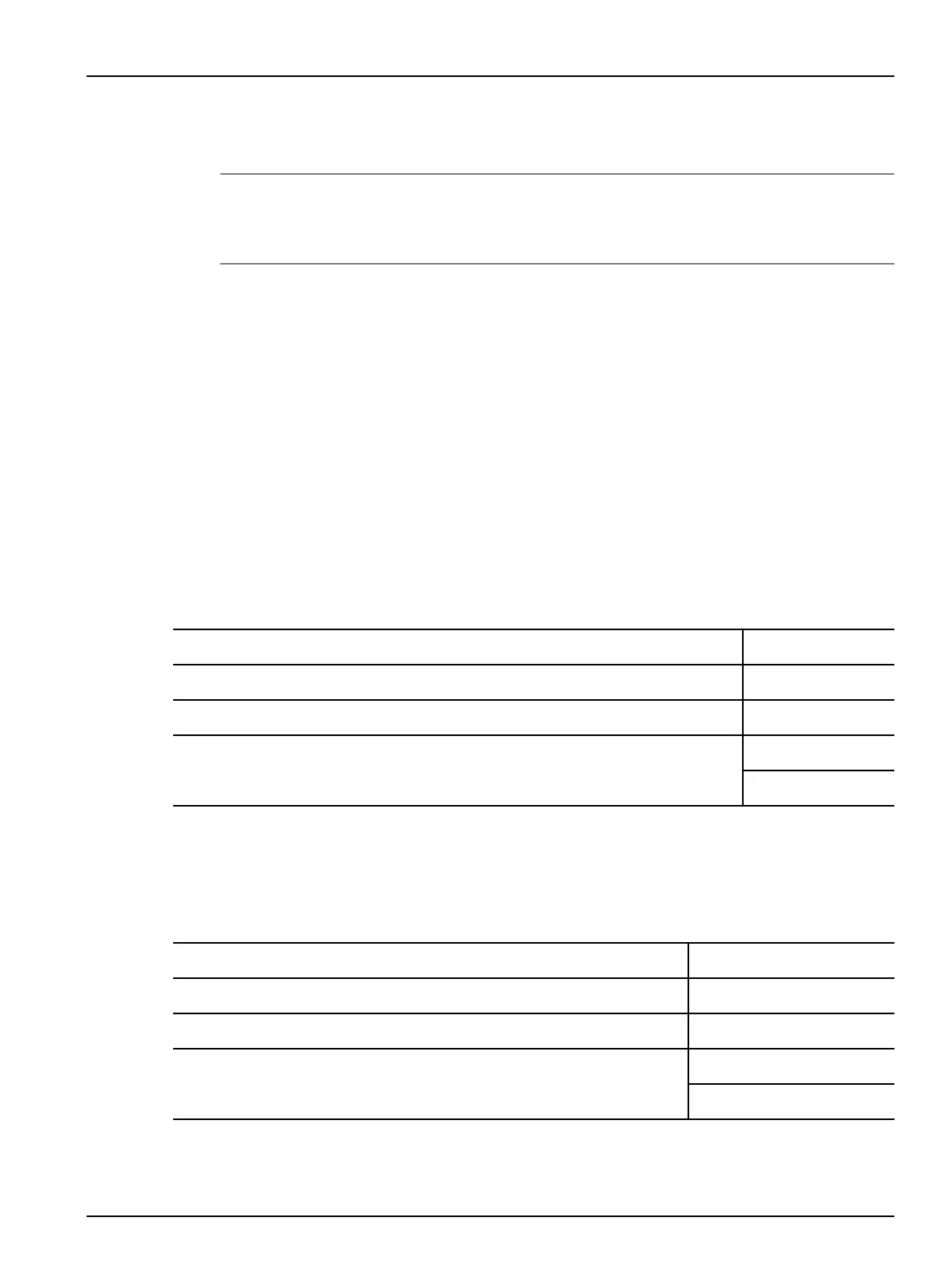

3.7 Hydraulic Cooling Water Specications

Description Value

Maximum temperature at inlet 35 °C (95 °F)

Maximum pressure 8 bar (116 psi)

Maximum number of actuators per cooling circuit and/or maximum temperature

at outlet

3 actuators

40 °C (104 °F)

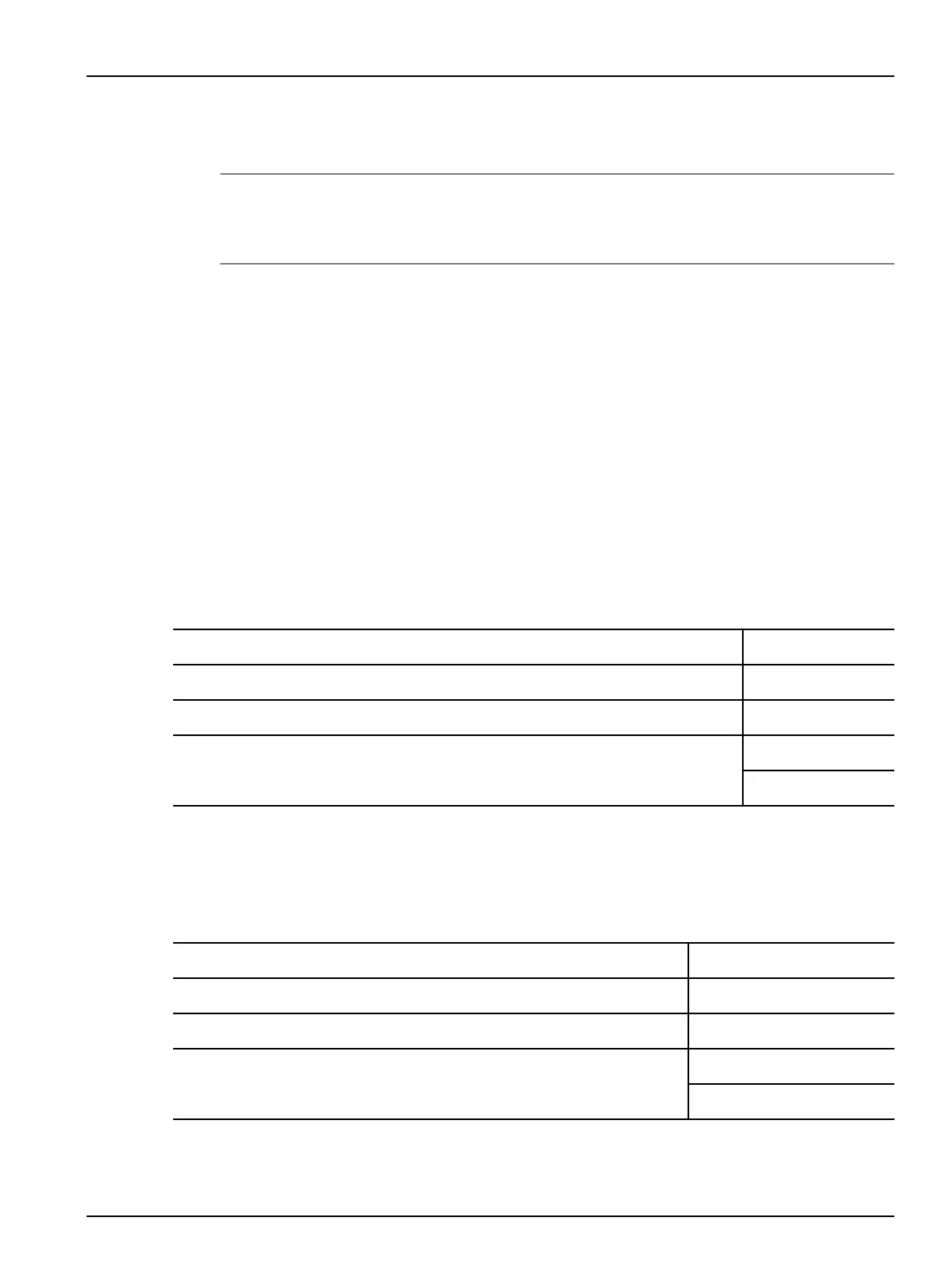

3.8 Pneumatic Cooling Water Specications

Description Value

Maximum temperature at inlet 90 °C (194 °F)

Maximum pressure 8 bar (116 psi)

Maximum number of actuators per cooling circuit and/or maximum

temperature at outlet

3 actuators

40 °C (104 °F)

Hot Runner Installation Manual v 2.2 — March 2021 Specications

Pneumatic Specications 33

Loading...

Loading...