36 of 140

Version 2.5 (11/2020) UL

Translation of the original operating manual

Start-up and operation

• IP addresses of neighbouring MultiControls (with ZPA and ZPA+ programs)

IP address upstream: Address of the MultiControl from which articles, trays, materials to be conveyed, products, etc.

are transferred

IP address downstream: Address of the MultiControl to which articles, trays, materials to be conveyed, products,

etc. are delivered

• Denition as to whether the PLC data is in big-endian format (High/Low byte switched)

Press the "Submit" button to transfer the modied parameters to the MultiControl.

NOTE

Irreparable damage to the MultiControl due to premature shutdown of the supply voltage

¾ Ensure that the power supply is not interrupted during the entire process of changing the bus type until the

restart is complete. This process takes approx. two minutes.

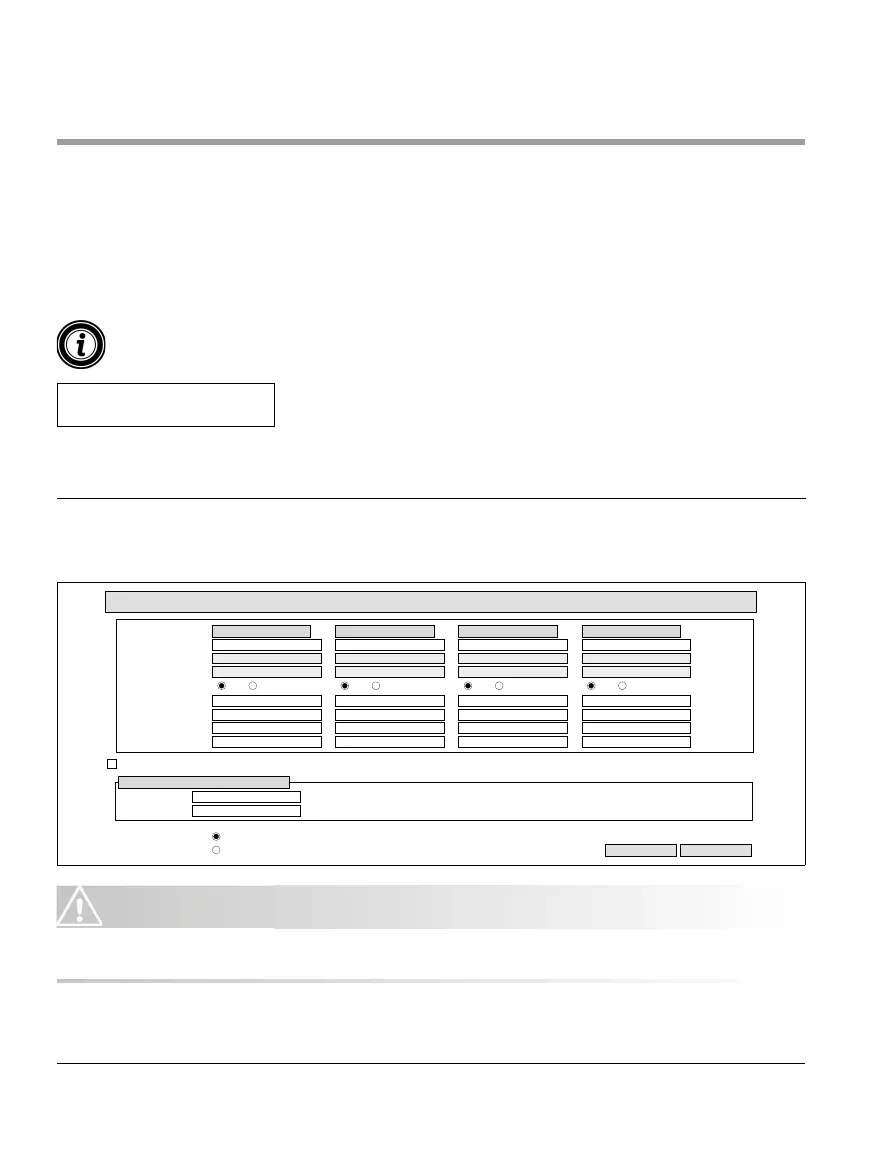

Motor Settings

Motor Settings

Motor 3

Submit Reset

Motor 4Motor 2Motor 1

Motor Type

Roller Diameter [mm]

Gearing Ratio

Direction

Normal Speed [m/s]:

Alternate Speed [m/s]:

Acceleration [m/s2]:

Decceleration [m/s2]:

EC5000

50.0

49:1

1.00

0.50

0.00

0.00

CW

CCW

EC5000

50.0

49:1

1.00

0.50

0.00

0.00

CW

CCW

Disabled

50.0

none

1.00

0.50

0.00

0.00

CW

CCW

Disabled

50.0

none

1.00

0.50

0.00

0.00

CW

CCW

Apply Motor 1 Settings to all

Start Delay [ms]:

Avoid parallel Motor Start/Stop - ZPA

100

100Stop Delay [ms]:

28 V

26 VBrake Chopper Level:

CAUTION

Risk of malfunction!

¾ Change the motor conguration via web browser only when motors are stopped!

Loading...

Loading...