DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

ELECTRONIC SUB-SYSTEMS

5.8 MISCELLANEOUS

39

– Printed 692.68.999 – 3 Ed. - Base 08-2020

5.8.2 Interventions for modifying wheelbase and overhang

Should it be necessary to lengthen the wires on the chassis owing to the new dimensions of wheelbase and overhang, a watertight

junction box must be used which has the same characteristics as those used on the standard vehicle. The electrical components

used such as wires, connectors, terminal blocks, conduits etc. must be of the same type as those used originally and must be cor-

rectly fitted.

As for the functionality of the electronic control devices, junctions are not permitted: the cable must be replaced with a new one

with similar characteristics to the one used on the vehicle and of adequate length.

5.8.3 Pre-installation for trailer

If the repetition of rear lights is necessary, the vehicle must be fitted with the 13-pin trailer socket.

Do not hook up directly to the vehicle's light cables. This results in current overloads which are recognised as malfunctions by the

on-board computer.

If the vehicle is not equipped with a trailer socket, it is possible to order a special kit comprising of:

● control unit with fastening bracket;

● chassis cable with trailer configuration;

● rear bridle for trailer socket.

For proper instillation it is necessary to:

● mount the electronic control unit onto the bracket;

● mount the entire bracket plus control unit onto the chassis as shown in Figure 41;

● replace the chassis cable with the new cable configured for the trailer socket (see Figure 42);

● fa connection bridle for the 13-pin socket compatible with the type of hook (high or low) (see Figure 43);

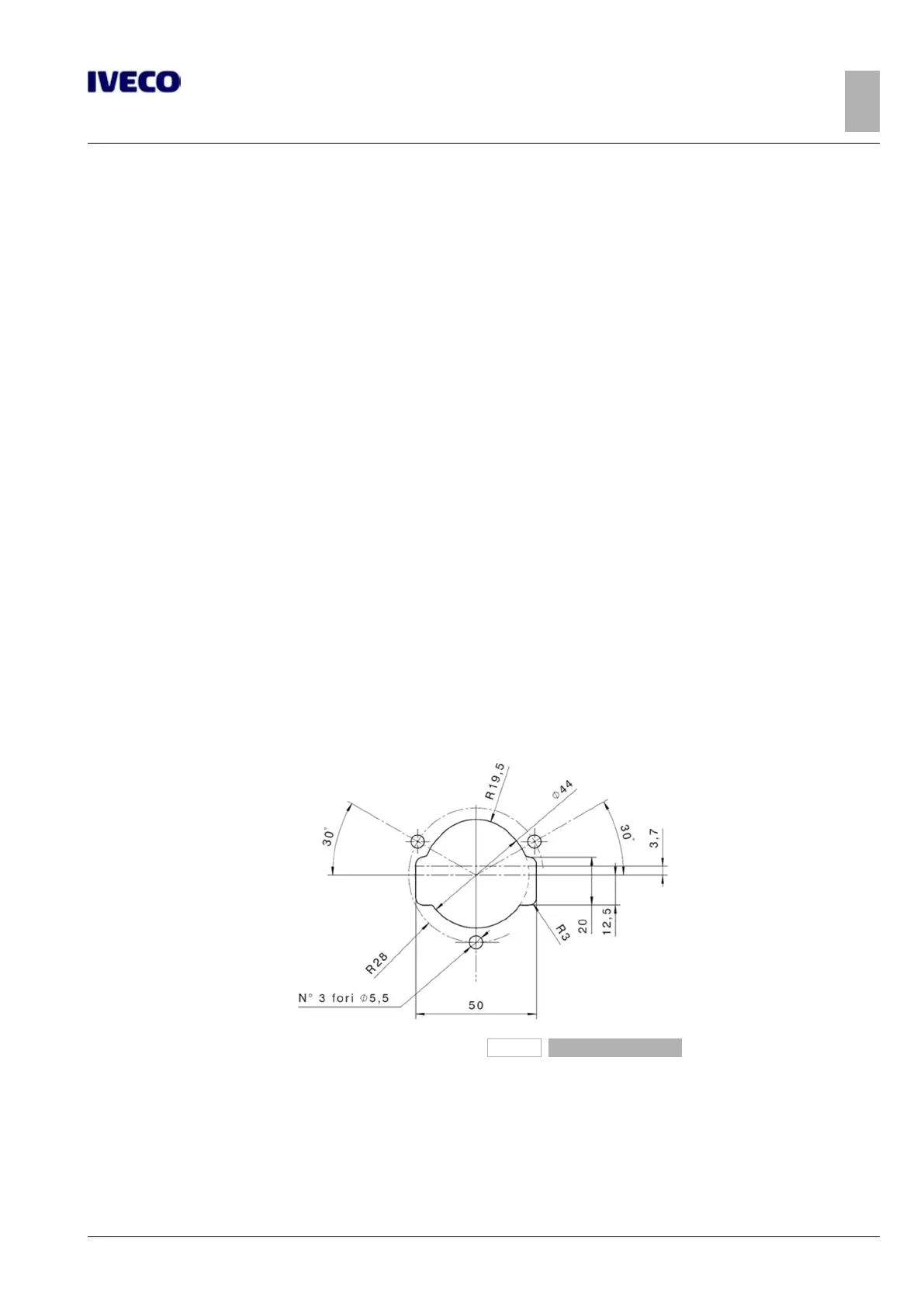

● Ensure that the seat securing the 13-pin socket complies with the distances indicated in Figure 40.

277293

Figure 40

Loading...

Loading...