DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.1 CHASSIS MODIFICATION STANDARDS

5

– Printed 692.68.999 – 3 Ed. - Base 08-2020

CHASSIS INTERVENTIONS

2.1 CHASSIS MODIFICATION STANDARDS

2.1.1 General precautions

Keep in mind that:

● weldings on the supporting structures of the chassis are absolutely forbidden (except as prescribed in Para-

graph"Weldings" ( ➠ Page 8) and in Chapters 2.4 ( ➠ Page 14), and 2.5 ( ➠ Page 17));

● no holes may be drilled on the wings of the side members (except for that stated in Chapter 3.3 - Paragraph

"Choosing the type of connection" );

● for cases where modifications to nailed unions are allowed, the nails may be replaced with flanged head screws or with hex

head screws classed 8.8 with the next higher class diameter and nuts fitted with an anti-unscrewing system. Screws larger than

M14 may not be used (maximum hole diameter of 15 mm), unless otherwise specified;

● for cases where unions that require screws are restored, the suitability of these screws must be checked before being re-

used, and they must be tightened to the appropriate torque;

▶ With regards to refitting safety components, it is prohibited to re-use the same screws they

must be tightened to the specified torque (contact the Service Network for the value).

● for cases involving remounting of safety components where nails are replaced by screws, the union must be checked again

after about 500 - 1000 km of travel.

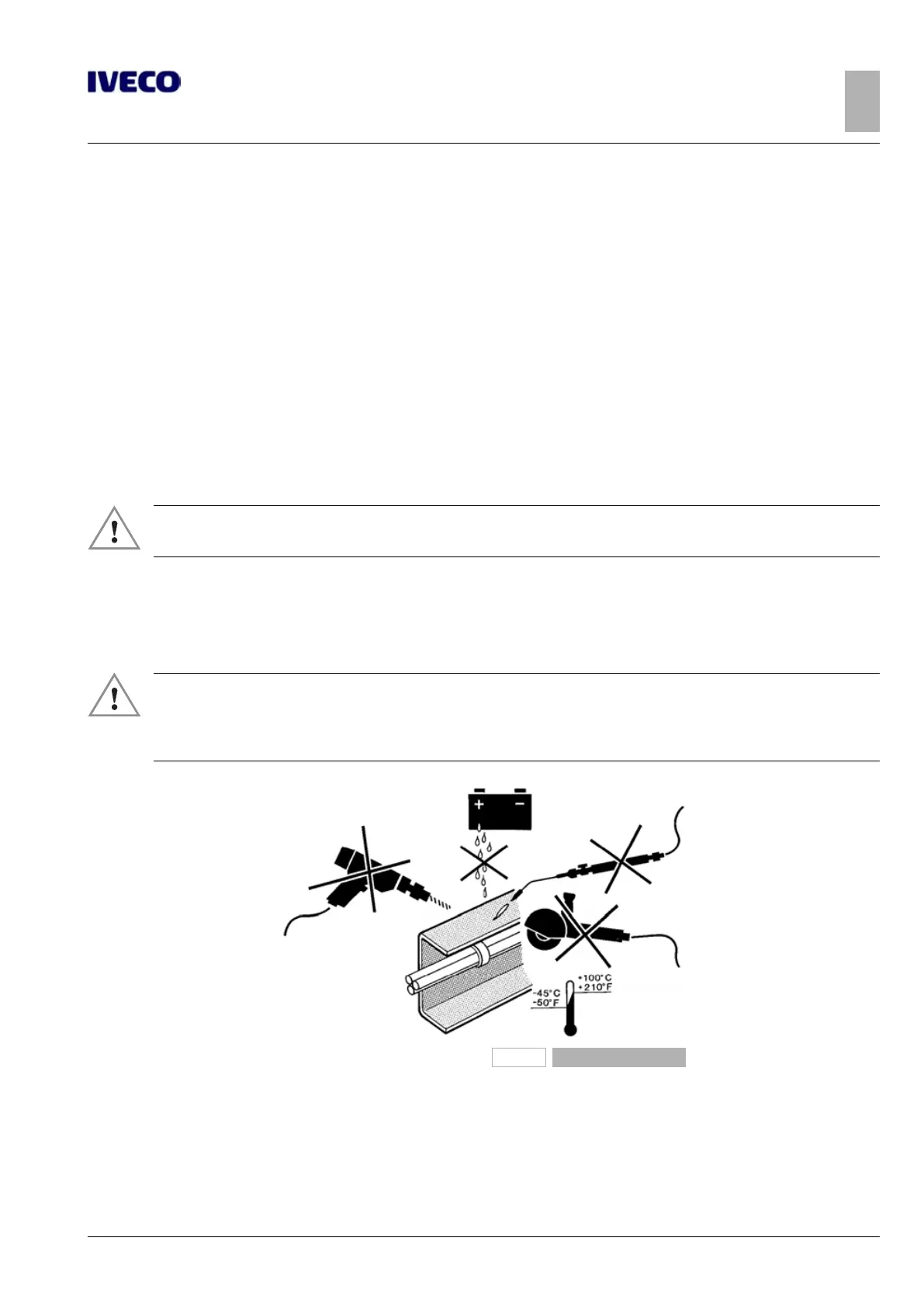

2.1.2 Special precautions

▶ During operations involving welding, drilling, grinding or cutting carried out near the brake pipes

or wiring, always disconnect the battery to prevent damage to the electronic control units. It is

also necessary to adopt appropriate measures to protect these pipes and cables, even including

removal if necessary (respect the indications provided in Chapters 2.15 and 5.4).

91444

Figure 1

Loading...

Loading...