DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

APPLICATIONS OF SUPERSTRUCTURES

3.3 CONNECTION BETWEEN CHASSIS AND SUBFRAME

11

– Printed 692.68.999 – 3 Ed. - Base 08-2020

3.2.4 Self-supporting superstructures with subframe functions

The interposition of a subframe (longitudinal and transverse) can be omitted in the case of installation of self-supporting super-

structures (e.g. vans, tanks), or when the underlying structure of the equipment to be installed already has the subframe conforma-

tion.

3.3 CONNECTION BETWEEN CHASSIS AND SUBFRAME

The connections between the chassis and the subframe must be flexible.

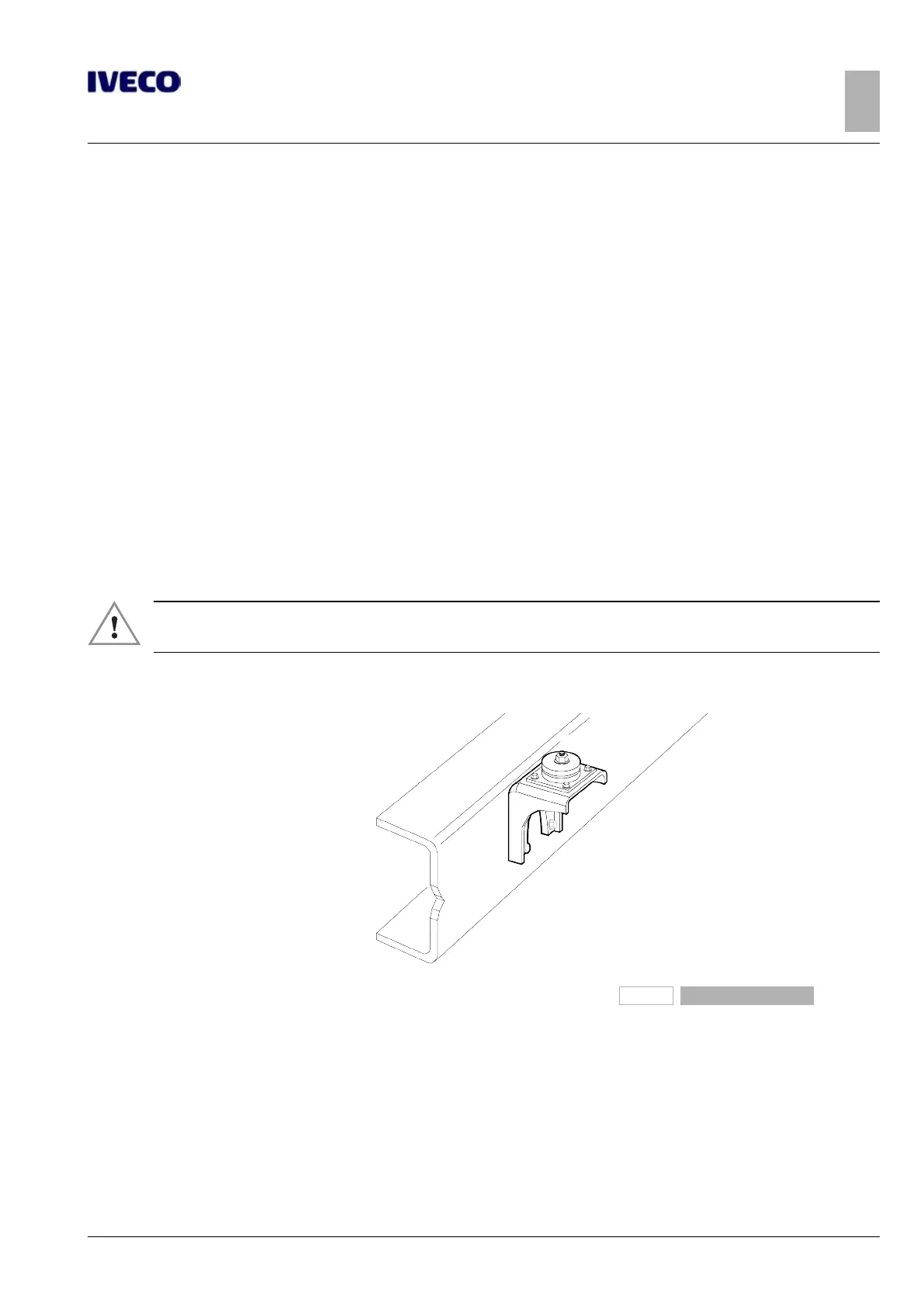

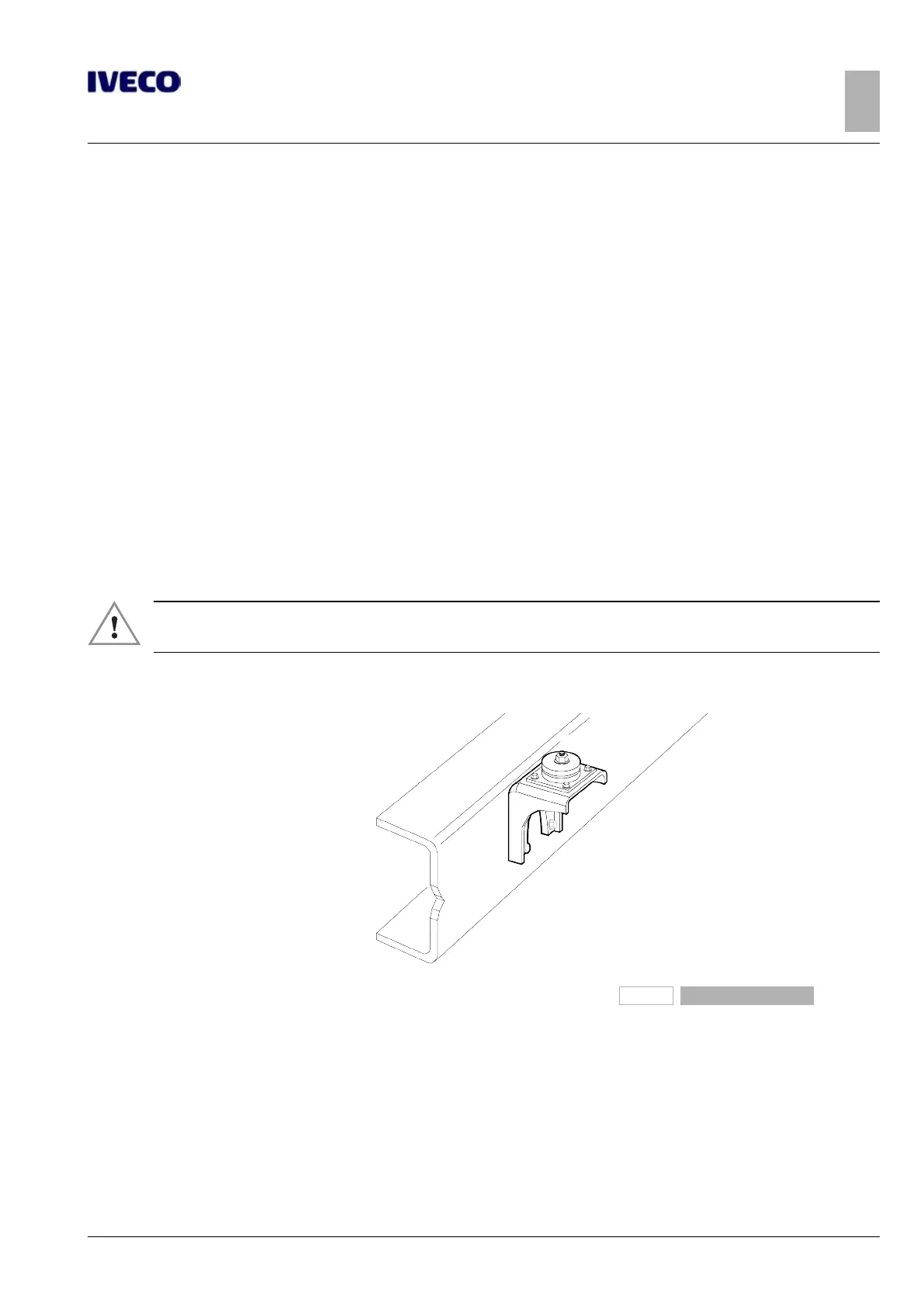

This solution (see Figure 7) allows limited movement between the two structures and makes it possible for respective resistant

sections to be considered "cooperating", as each takes on a share of the bending moment proportional to its moment of inertia.

For the correct realization of the connection, the fastenings must:

● be adequately distributed along the length of the subframe;

● use elements already pre-installed on the chassis;

● use screws with a resistance class of not less than 8.8 and anti-loosening nuts.

The first fixing point should be positioned approx 250–350 mm from the front end of the subframe, especially in the case of su-

perstructures with concentrated loads behind the cab (e.g. crane, body tilting cylinder, etc.). This is to limit the magnitude of the

stresses on the chassis and to provide greater stability. Provide additional connections if necessary.

▶ In anchoring the structure to the chassis, welding must not be performed on the vehicle chassis,

nor may holes be drilled into the wings of the side members.

3.3.1 Connection with brackets

261820

Figure 7

The brackets must be fixed to the rib of the side members of the vehicle by means of screws or nails.

In order to better contain the transverse loads, the brackets are normally applied so that there is a slight protrusion perpendicular

to the upper edge of the chassis. If however the brackets have to be applied flush, the side guide for the superstructure must be

secured with other devices (e.g. using guide plates connected only to the subframe, or only to the vehicle chassis.

If the vehicle chassis is already equipped with brackets for coupling of a body of a type established by IVECO, these brackets must

be used for this purpose. For the brackets applied to the subframe or to the superstructure, resistance characteristics not less than

those originally mounted on the vehicle should be provided (see Table 2.7 and Table 3.1).

Loading...

Loading...