36

DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.15 WORK ON THE BRAKING SYSTEM

– Printed 692.68.999 – 3 Ed. - Base 08-2020

● may affect distance from ground of the rear under-run protection device and, in this case, a check on standard compliance is

required; if necessary the support brackets must be replaced with appropriate and approved counterparts (see chapter 2.20

( ➠ Page 42));

● requires compliance of the transversal limit edge to be checked.

▶ Tyres of different size and type of structure cannot be mounted on the same axle.

The vehicle must then be presented to the competent Body that will inspect the new tyres and the vehicle documents.

▶ If vehicle configuration requires the wheels to be removed, make sure that the contact surfaces

between rim and connection flange are clean and free of corrosion when remounting the wheels.

Furthermore, tightening of the wheel studs to torque must be ensured in compliance with

IVECO Standard 17-9219.

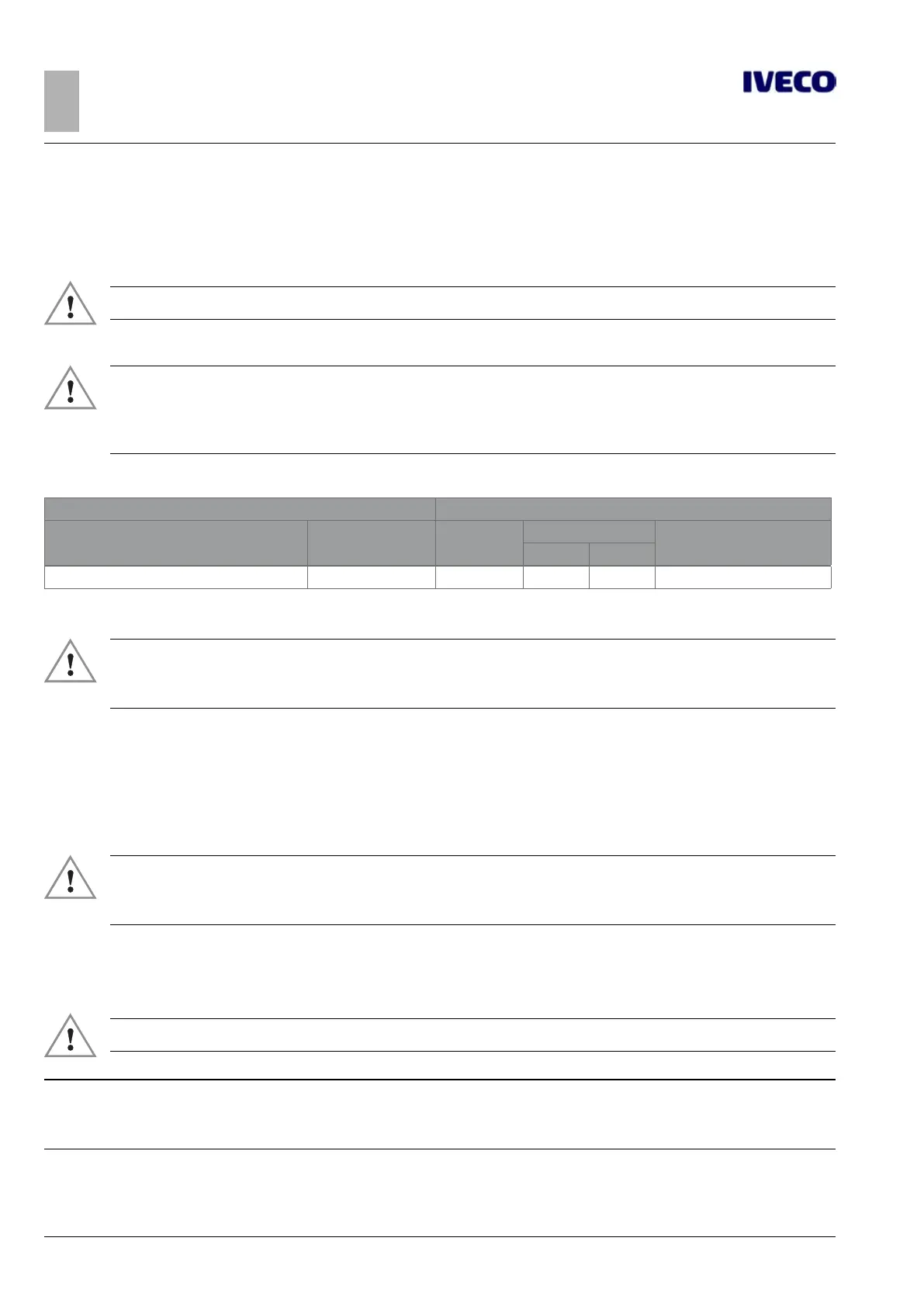

Table 2.14 - Wheel tightening torque according to IVECO STD 17-9219

CONNECTING ELEMENTS TIGHTENING

Name Thread CLASS

Torque [Nm]

FEATURES "S"

(*)

Min Max

Front and rear wheel mounting Stud M18x1.5 II 335 410 "S"

(*)

Characteristic "S": safety tightening (see IVECO std. 19-0405).

▶ If using brackets to mount aesthetic studs positioned between the rim / lug or stud, or if using

rims thicker than the original, geometric mounting functionality must be ensured through ap-

propriate lengths of stud threading in the locking hole.

2.15 WORK ON THE BRAKING SYSTEM

2.15.1 General information

The braking system, together with its components, is of fundamental importance in terms of safety.

▶ No modifications to the adjustment unit, control valve, brake cylinders, valves, pedalbox, com-

ponents of the AEBS, brake callipers, discs and pads (with the exception of normal replacement

with spare parts), since they are safety components.

If required by national regulations, the vehicle must be presented to the competent authority for testing.

2.15.2 Brake pipe

▶ It is absolutely forbidden to weld the pipes.

Note

In the case of changes to the cantilever, the brake lines involved should preferably be replaced with new pipes and in one piece. If

it is not possible to use one-piece pipes, the couplings to be used must be of the same type as the original ones in the rest of the

system.

In the event of replacements the minimum internal dimensions, material and curvature radii of the pre-existing pipes must be re-

spected.

Loading...

Loading...