6

DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

APPLICATIONS OF SUPERSTRUCTURES

3.1 CONSTRUCTION OF THE SUBFRAME

– Printed 692.68.999 – 3 Ed. - Base 08-2020

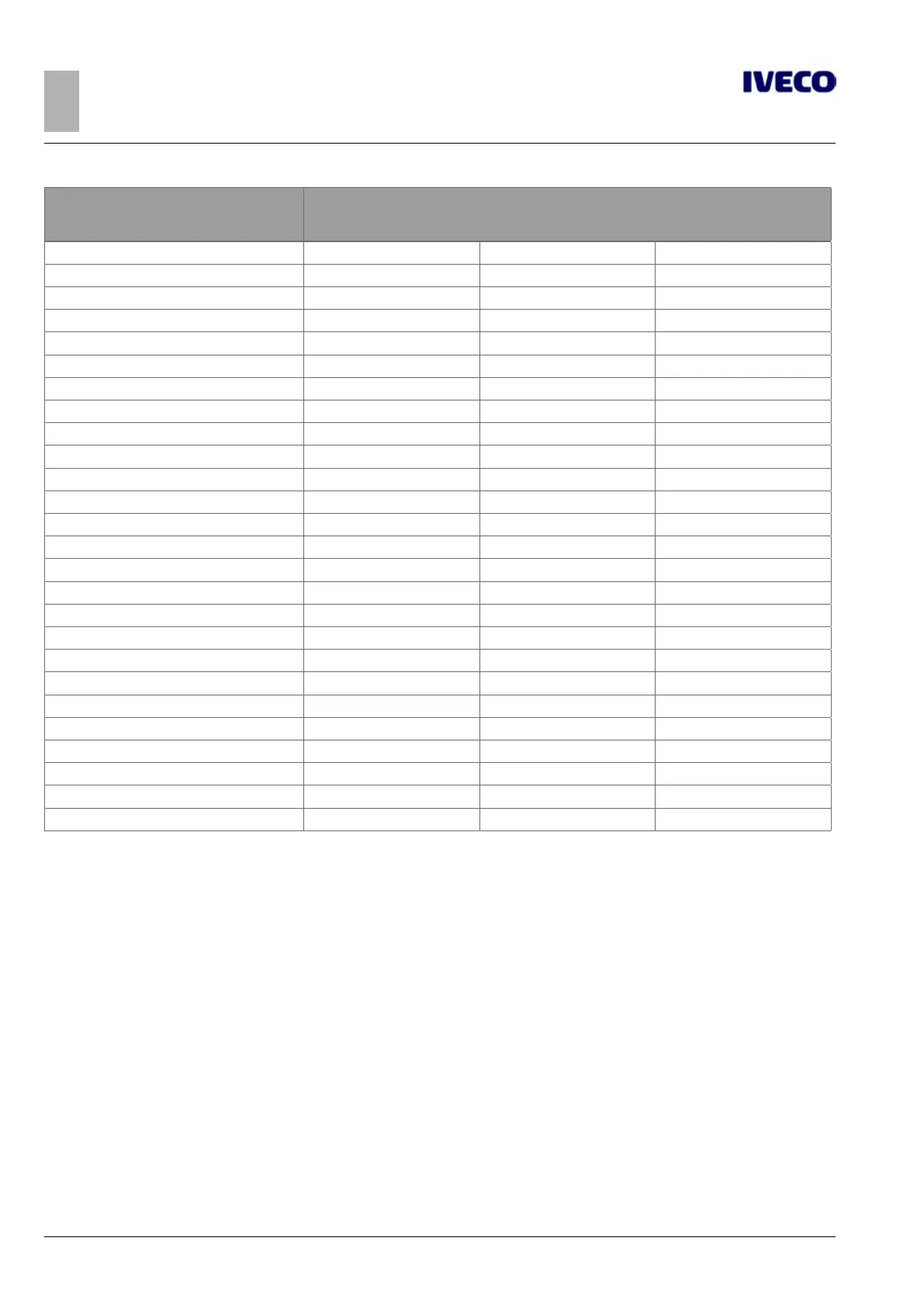

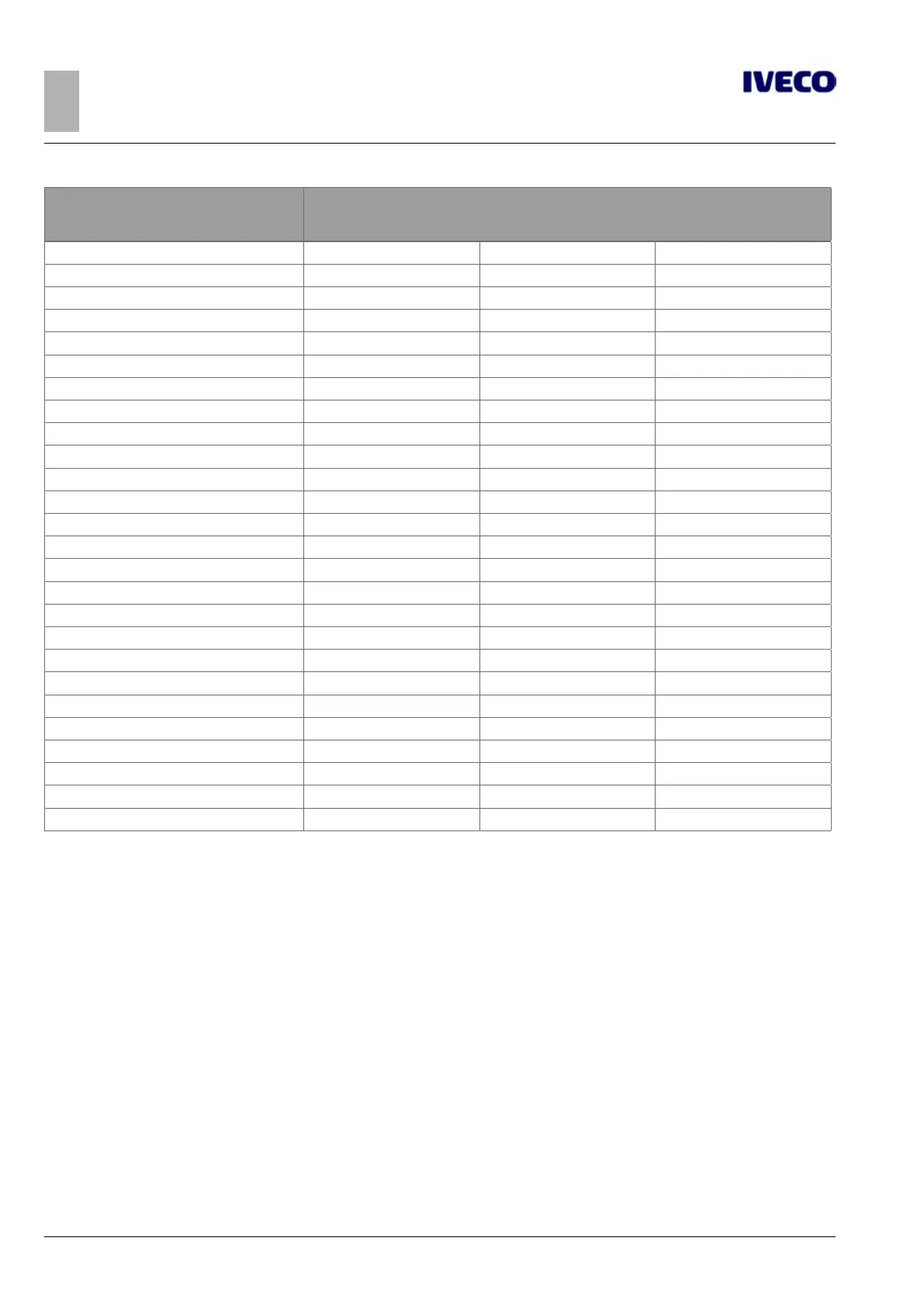

Section modulus W

x

[cm

3

]

Recommended C profile

[mm]

31 ≤ W ≤ 33 80 X 60 X 8 100 X 60 X 5

34 ≤ W ≤ 36 100 X 60 X 6

37 ≤ W ≤ 41 100 X 60 X 7

42 ≤ W ≤ 45 80 X 80 X 8 100 X 60 X 8

46 ≤ W ≤ 52 120 X 60 X 6 120 X 60 X 7

53 ≤ W ≤ 58 120 X 60 X 8

59 ≤ W ≤ 65 140 X 60 X 7 120 X 70 X 7

66 ≤ W ≤ 72 140 X 60 X 8 120 X 80 X 8

73 ≤ W≤ 79 160 X 60 X 7

80 ≤ W≤ 88 180 X 60 X 8

89 ≤ W≤ 93 160 X 70 X 7 180 X 60 X 7 140 X 80 X 8

94 ≤ W≤ 104 180 X 60 X 8

105 ≤ W≤ 122 200 X 80 X 6 200 X 60 X 8 180 X 70 X 7

123 ≤ W≤ 126 220 X 60 X 7

127 ≤ W≤ 141 220 X 60 X 8

142 ≤ W≤ 160 200 X 80 X 8 240 X 60 X 8

161 ≤ W≤ 178 220 X 80 X 8 240 X 70 X 8

179 ≤ W≤ 201 250 X 80 X 7 260 X 70 X 8

202 ≤ W≤ 220 250 X 80 X 8 260 X 80 X 8

221 ≤ W≤ 224 220 X 80 X 8 280 X 70 X 8

225 ≤ W≤ 245 250 X 100 X 8 280 X 80 X 8

246 ≤ W ≤ 286 280 X 100 X 8

290 ≤ W ≤ 316 300 X 80 X 8

316 ≤ W ≤ 380 340 X 100 X 8

440 380 X 100 X 8

480 400 X 100 X 8

While the section modulus represents a decisive value for the stress of the material, the moment of inertia is important mainly for

the flexural hardness and for the quota of the bending moment to be taken, depending on the connection used.

3.1.3 Aluminium subframe

When using materials with different characteristics from those of steel, the size and structure of the subframe must be appropri-

ately adjusted, ensuring at least the equivalent performance levels.

In particular, in the case of aluminium:

1. If the subframe serves to evenly distribute the load while the task of withstanding stress is left to the chassis, profiles with

dimensions similar to those indicated for the steel can be used.

Typical examples of subframes for fixed bodies, vans and tankers, provided that the supports are continuous and close to-

gether or in the immediate vicinity of the suspension mounts.

2. If the subframe serves above all to assist in terms of robustness and rigidity (for example, superstructures with high concen-

trated loads, tipping bodies, cranes, centre axle trailers, etc.), make sure that it ensures bending and torsional resistance at least

equal to that of a type-approved subframe in steel.

In defining the minimum dimensions of the profiles, in addition to the limit of the permitted stress, the different elastic modu-

lus of aluminium in relation to steel must be taken into consideration (approx. 7,000 kg/mm

2

compared to 21,000 kg/mm

2

).

Loading...

Loading...