DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.4 WHEELBASE MODIFICATION

15

– Printed 692.68.999 – 3 Ed. - Base 08-2020

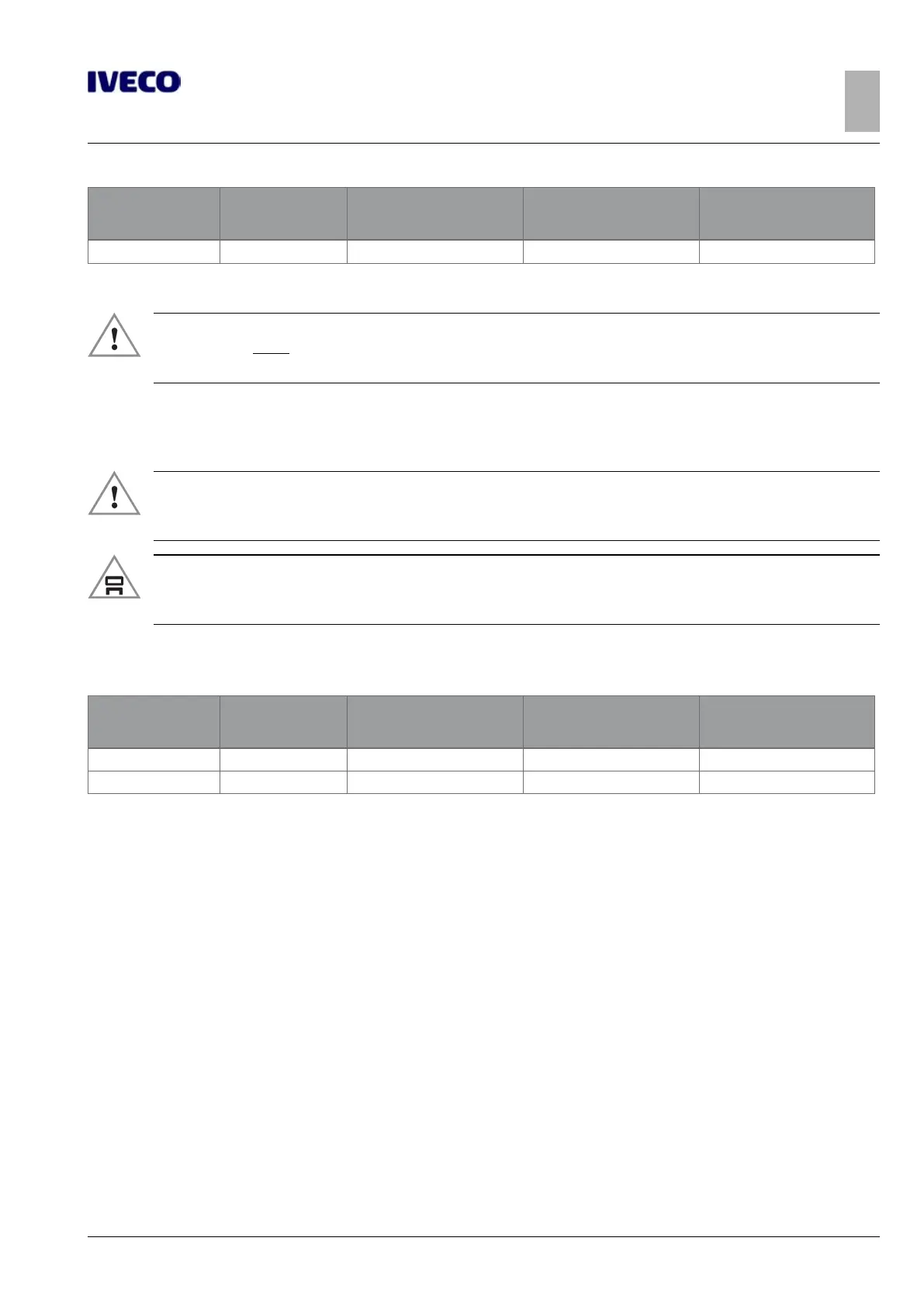

Model

Suspension

front

(*)

Maximum load

on front axle

[kg]

Maximum load

on rear axle

[kg]

Maximum value

of wheelbase

[mm]

70C Quad-Tor 2700 5000 4175

(*)

Quad-Tor = torsion bar

▶ If the wheelbase is to be lengthened beyond the maximum value approved, these steering

solutions must be authorised by IVECO. Any type approval tests are charged fully to the

Bodybuilder.

2.4.4 Impact on braking

Generally speaking, shortening the wheelbase will have a negative effect on braking.

▶ Modifications to the wheelbase on vehicles equipped with electronic control systems for braking,

grip and stability, require as mandatory the updating of the setting parameters (datasets) of the

relevant control units via IVECO teleservices.

▶ Wheelbases which can be technically realised depend on the vehicle type (model/version). For

wheelbases which are longer or shorter than the standard wheelbases, availability of the ESP

system setting parameters must be verified.

Table 2.10 lists the minimum values of the wheelbase approved by IVECO.

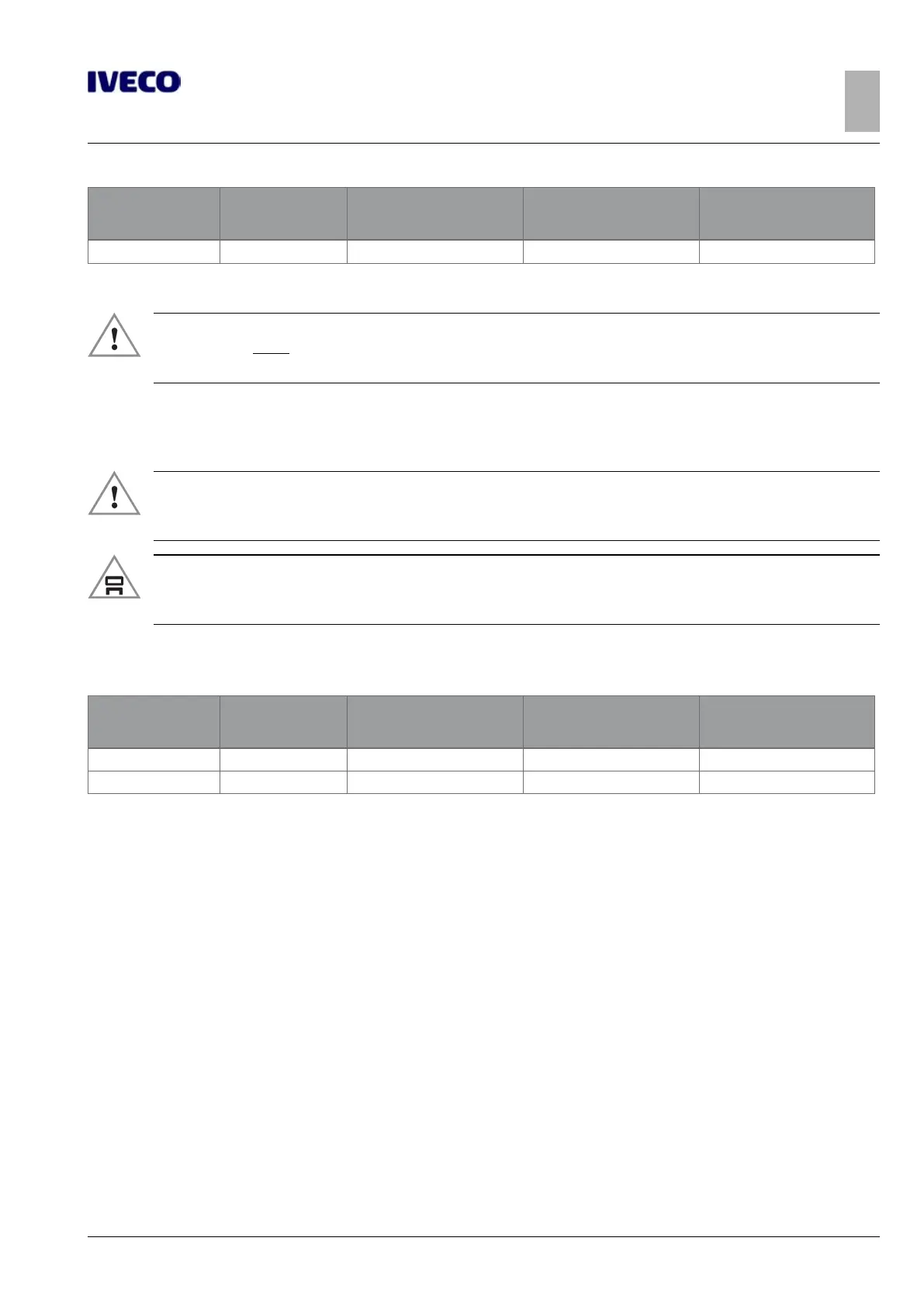

Table 2.10 - Minimum wheelbase

Model

Suspension

front

(*)

Maximum load

on front axle

[kg]

Maximum load

on rear axle

[kg]

Minimum value

of wheelbase

[mm]

55C Quad-Tor 2450 3700 3080

70C Quad-Tor 2700 5000 3080

(*)

Quad-Tor = torsion bar

2.4.5 Intervention procedure

Proceed as follows to obtain good results:

● position the vehicle so that the chassis is perfectly horizontal, use appropriate trestles;

● detach the propeller shafts, braking system hoses, cables and all other equipment that may interfere with proper work execu-

tion;

● identify the reference points on the frame (e.g: guide holes, suspension supports);

● mark the reference points with a slight punch mark on the top flaps on both side members, after having verified that the con-

junction line is at a perfect right angle with the longitudinal axle of the vehicle;

● if moving the suspension supports, identify the new position using the previously determined references;

● make sure that the new measurements are identical on both the right and left sides; the diagonal check, for lengths of at least

1500 mm must not yield deviations of over 2 mm;

● make the new holes using as jig - if any other tools are unavailable - the supports and gusset plates of the crossbars;

● secure the supports and crossbars using nails or screws; if using screws, bore the holes and use calibrated screws class 10.9

with anti-unscrewing nuts; if size allows, flanged head screws may be employed;

● if cutting the frame (to be carried out according to indications of the second item in "Welding Operations" - Paragraph "Weld-

ing" ( ➠ Page 8)) mark a second line of reference points so that the work area is set between the two lines (plan for a dis-

Loading...

Loading...