DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.15 WORK ON THE BRAKING SYSTEM

37

– Printed 692.68.999 – 3 Ed. - Base 08-2020

For procurement please contact IVECO Assistance Service, whereas for assembly the directions in IVECO STD 17-2403 must be

complied with.

▶ The total or partial painting of the brake pipes must be absolutely avoided and, for this purpose,

appropriate masking of the pipes must be provided.

Metal pipes

Additions and replacements must envisage:

● for materials, dimensions, couplings: Standard ISO 4038

● radii of curvature (referring to the centre line of the pipe ⌀ = 4.76 mm): min 25 mm

● tightening torque:

■

stiff pipes, couplings M10x1 and M12x1: 14–18 Nm

■ hoses, male couplings M10x1: 17–20 Nm

Preparation and assembly (IVECO STD 17-2403)

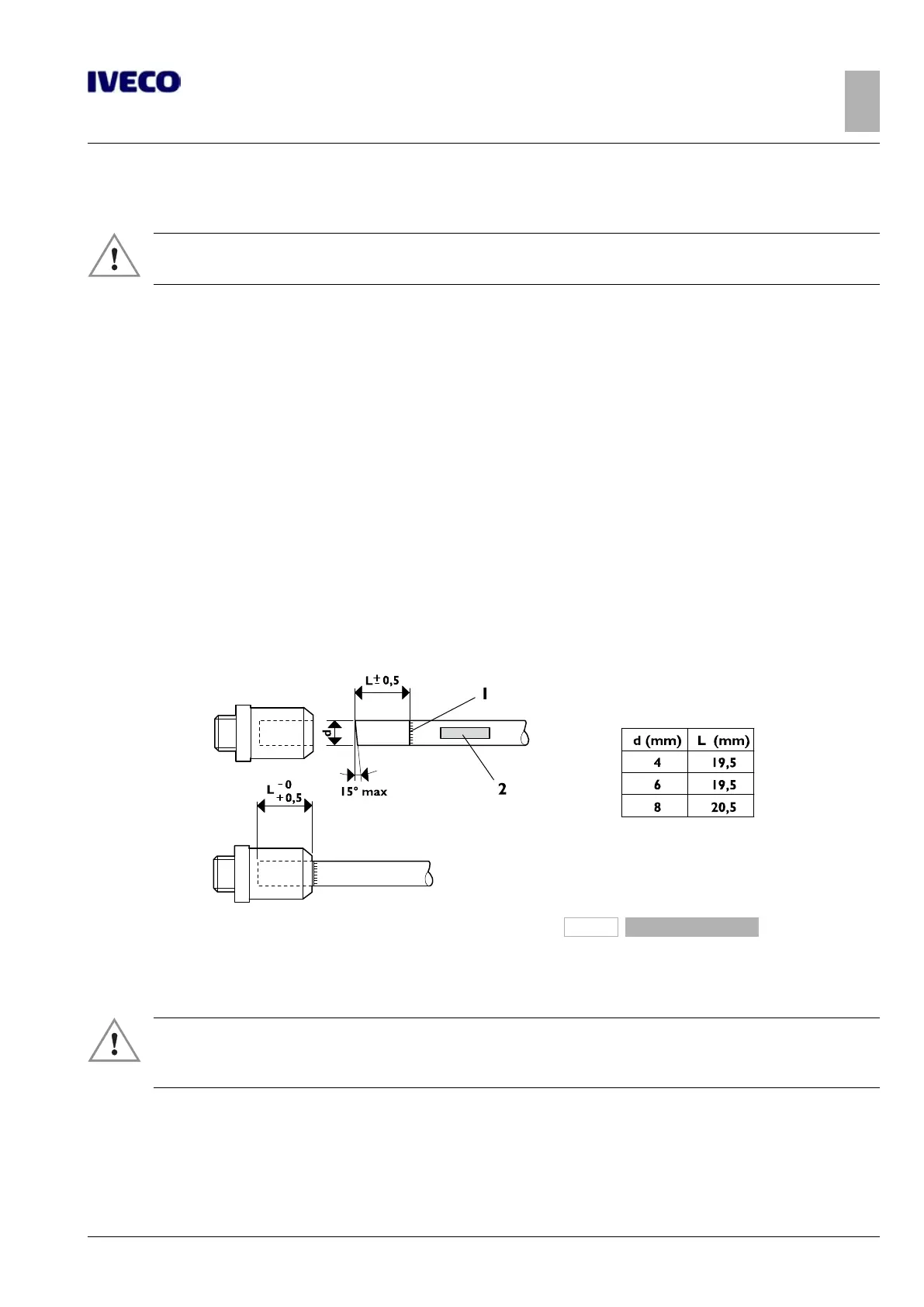

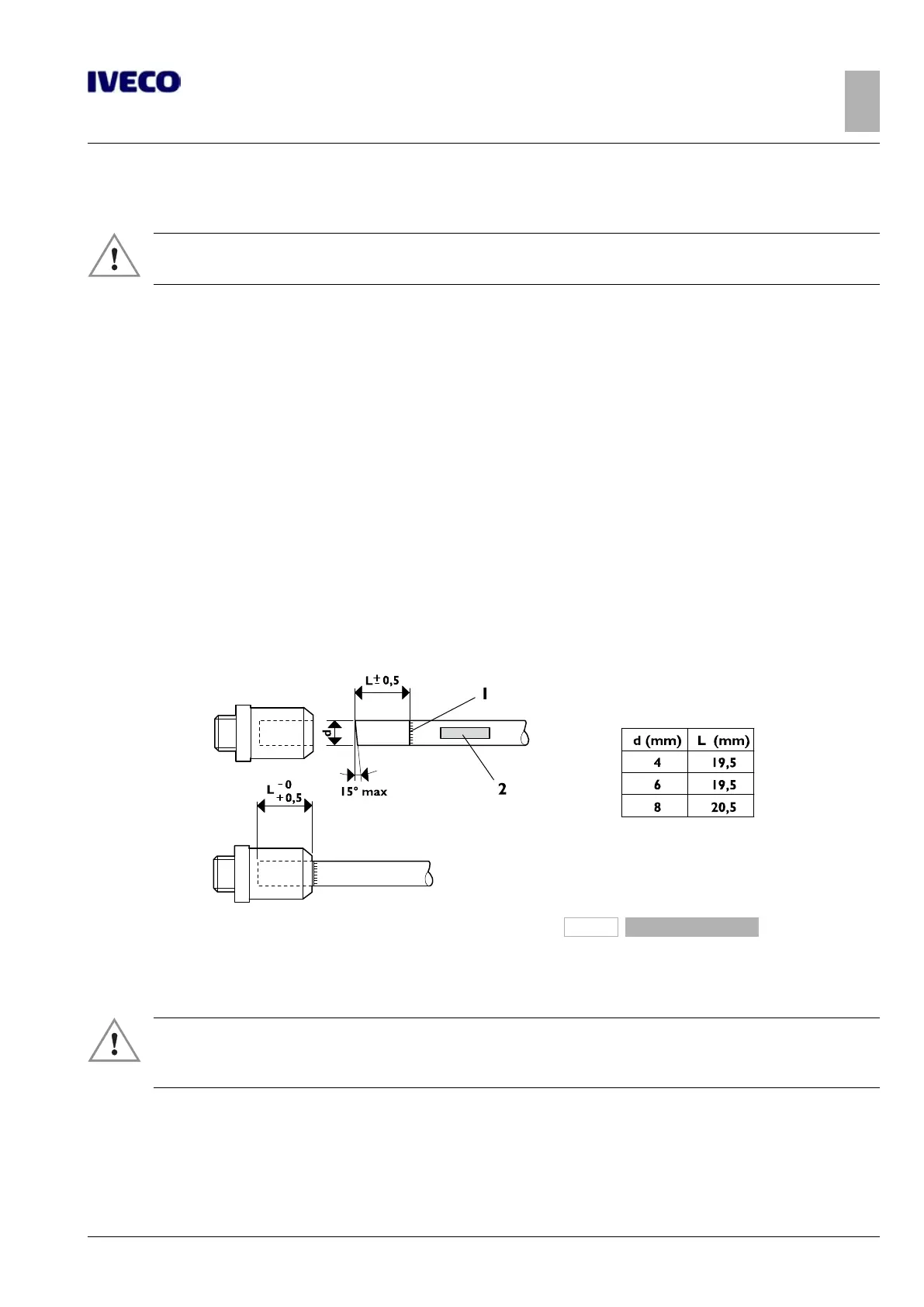

Cut the pipe at right angles (15° maximum error), using a special tool in order to avoid imperfections that affect the sealing.

Permanently mark the section of pipe (dimension L in Figure 18) to be inserted into the coupling to ensure secure sealing.

Mark the pipe to avoid assembly errors in case of subsequent repair operations.

As much as possible, use the same couplings as the original ones, or otherwise belonging to the normal production of specialised

manufacturers in the sector.

208209

Figure 18

1. Identification of pipe limit 2. Marking

As much as possible, use quick-fit couplings.

▶ For each intervention on the piping, verify whether there is the need, depending on the supplier,

to use always new couplings or if it is possible to reuse those originally present through the use of

appropriate tools (pliers).

When the space conditions require it (e.g. in proximity of curves), couplings with metal inserts can be used.

Before inserting the pipe into the coupling, screw the coupling into the threaded insert of the same component (e.g. pneumatic

valve), using the following values for tightening:

Loading...

Loading...