DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.2 DRILLS ON THE CHASSIS

9

– Printed 692.68.999 – 3 Ed. - Base 08-2020

● if an electric circuit breaker (main switch) is present, wait for it to complete the cycle;

● disconnect the negative pole from the battery;

● disconnect the positive pole of the battery without connecting it to ground; do NOT short-circuit the negative pole;

● disconnect all ECU connectors, proceed with caution and do not touch the ECU connector pins;

● disconnect the ECU from the vehicle for welds close to the ECU;

● connect the welder ground directly to the weld piece;

● protect the plastic pipes from heat and disconnect them if necessary;

● protect the surfaces of the leaf and air springs against any weld splashes when welds are performed nearby;

● avoid touching the spring leafs with the electrodes or pliers.

Weld operations

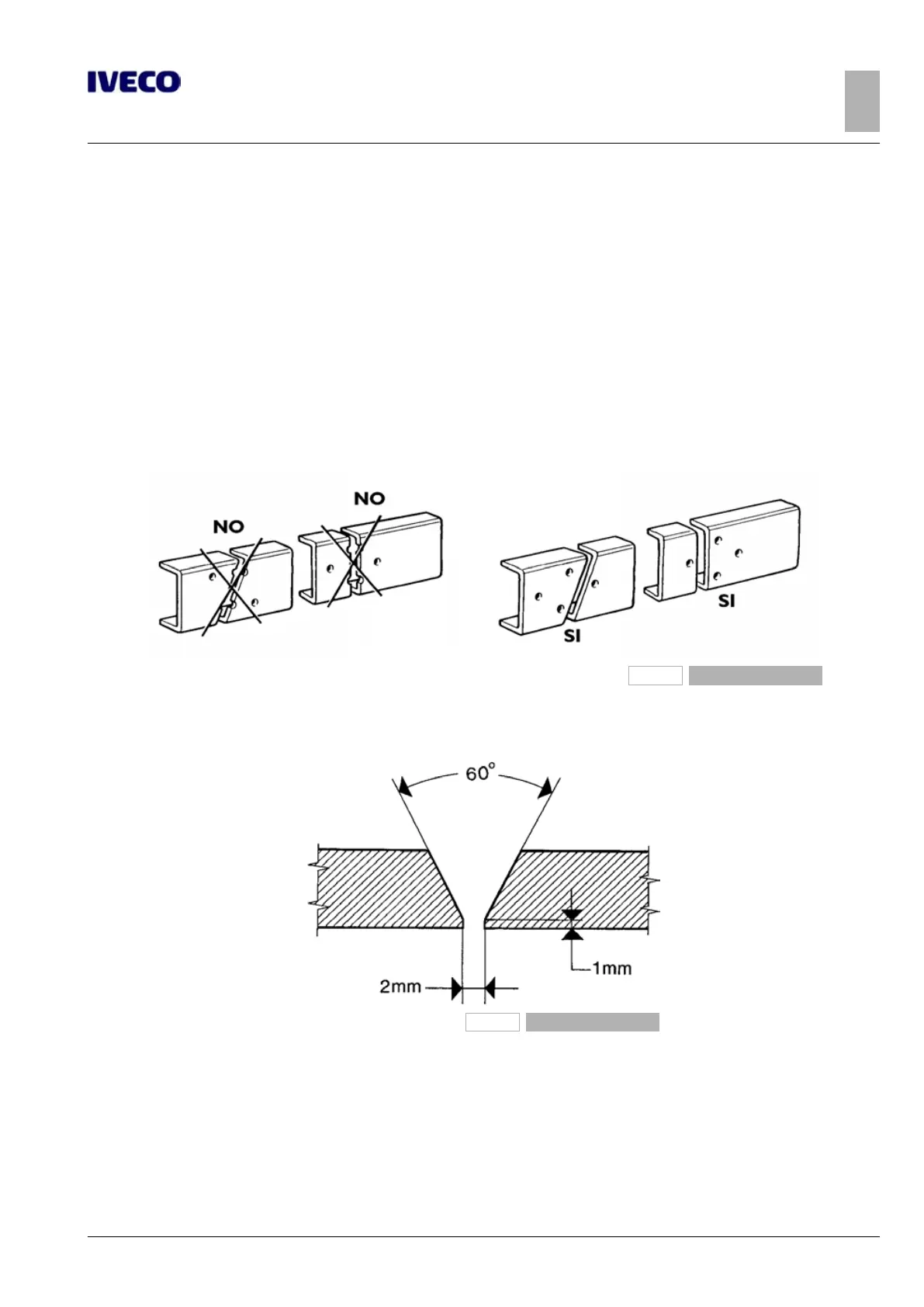

● Cut the side members with a skewed or vertical cut. Cuts are not permitted in areas where there are a high concentration of

stresses (e.g. spring brackets). The cutting line must not go through the holes on the side member (see Figure 4).

91446

Figure 4

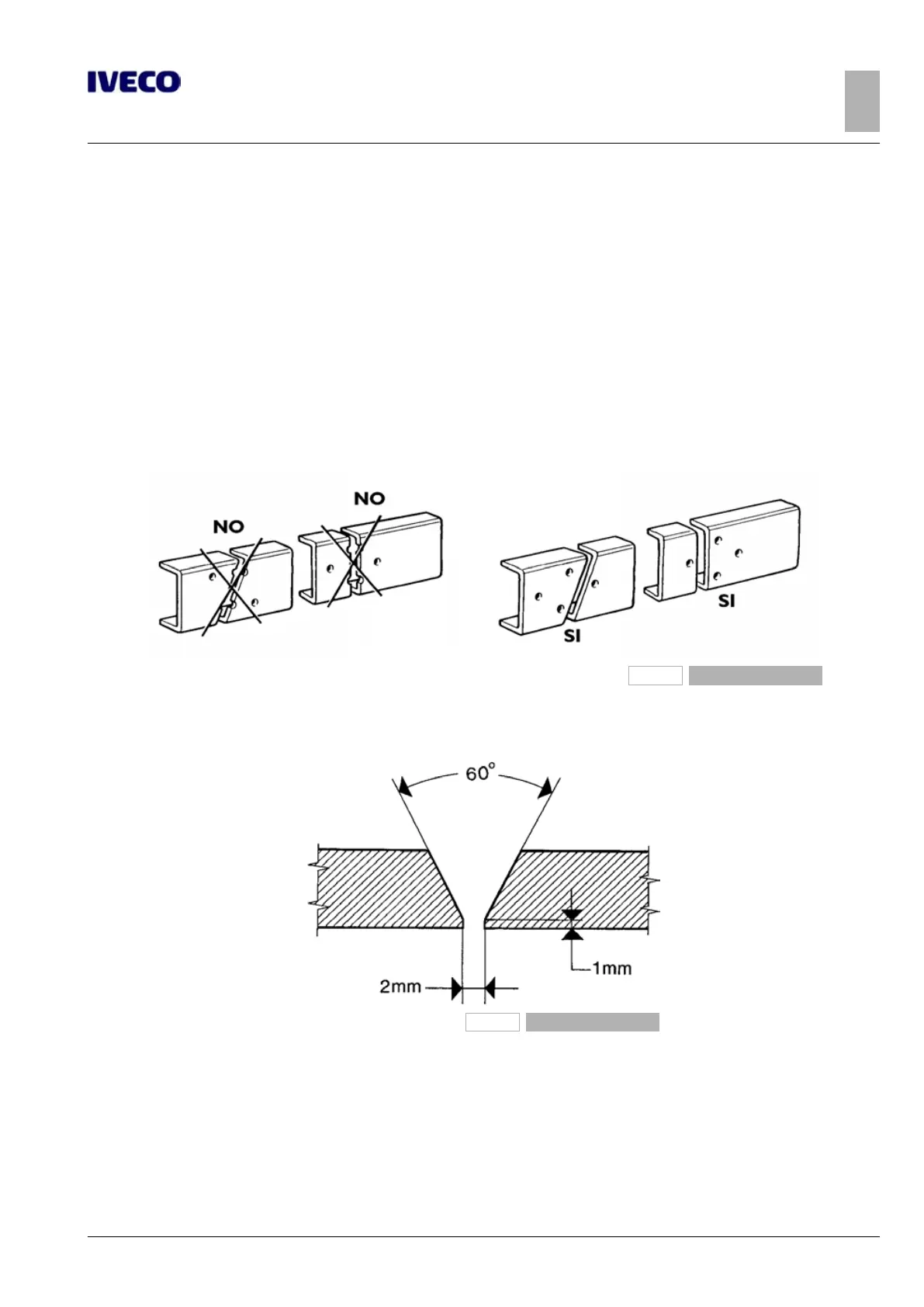

● Make a 60 degree bevel cut on the internal part of the side member of the parts to be joined, along the entire length of the

weld area (see Figure 5).

91447

Figure 5

● Arc weld the area with multiple steps and use base electrodes that are thoroughly dried.

Avoid power overloads; the welds must be free of marginal incisions and slag.

● Let the side members cool slowly and in a uniform fashion. No cooling with air jets, water or other means is allowed.

● Grind off the excess material.

● Mount steel corner reinforcements that have the same characteristics as the chassis; the minimum indicative sizes are shown in

Figure 3.

Loading...

Loading...