DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.3 RUST AND PAINT PROTECTION

11

– Printed 692.68.999 – 3 Ed. - Base 08-2020

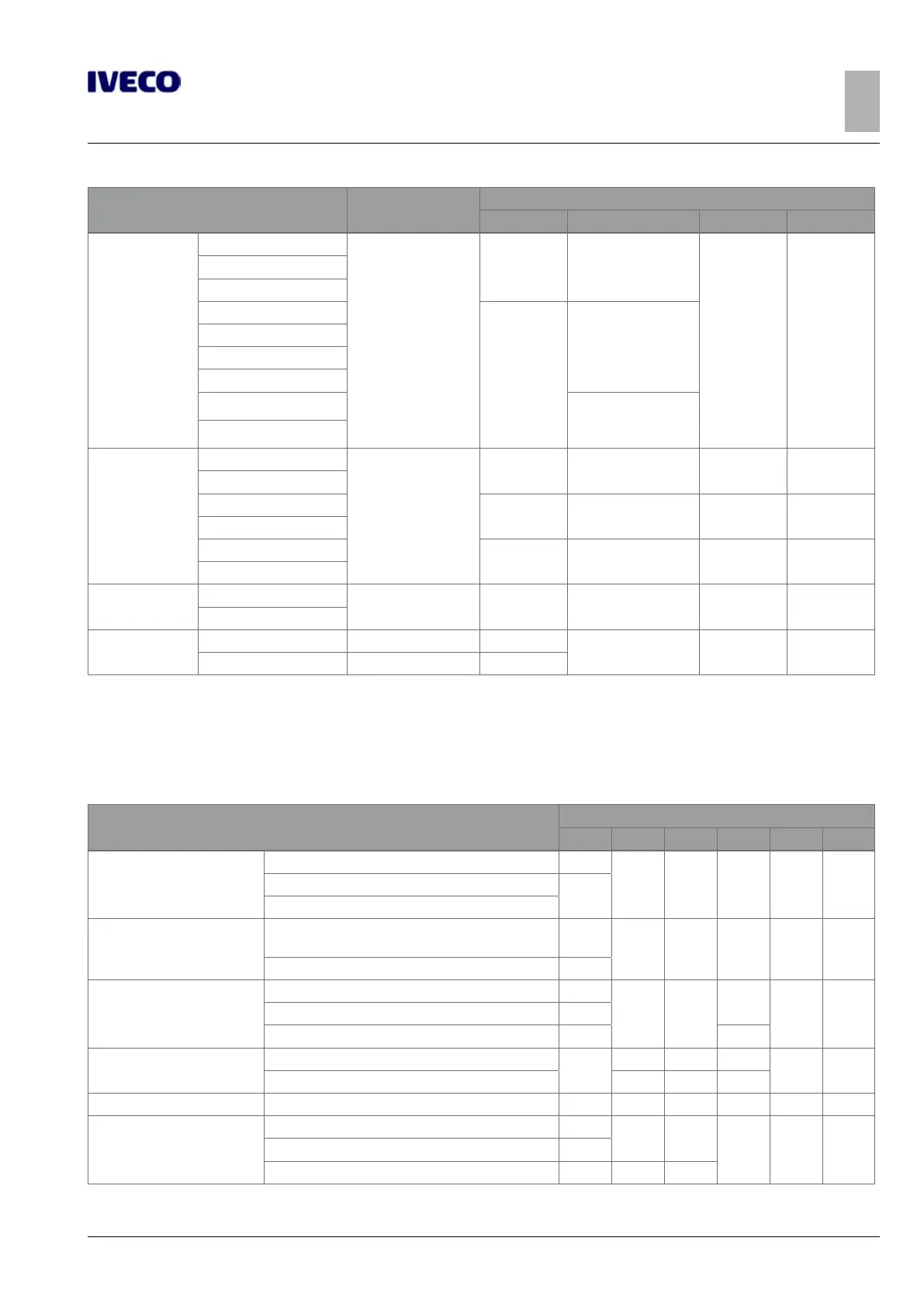

Type of protection

IVECO

standard

Classes

A B - B1 - B2 C D

Geomet

(2)

GEO 321-8 PML

18-1101

yes –

– –

GEO 321-8 PL

GEO 500-8 PL

GEO 321-5

–

yes

GEO 500-5

GEO 321-5 PM

GEO 321-5 PML

GEO 321-5 PL

yes

Class B1

wheel studs

GEO 500-5 PL

Zinc coating

(3)

Fe/Zn 12 II

18-1102

– – yes yes

Fe/Zn 7 IV

Fe/Zn 12 IV

– – yes yes

Fe/Zn 7 IV LUB

Fe/Zn 7 IV S

– yes yes yes

Fe/Zn 12 IV S

Alloy Zn-Ni

Fe/Zn Ni 7 VII S

18 - 1103 – yes yes yes

Fe/Zn Ni 7 IV

Aluminium

Anode oxidation 18-1148 yes

yes yes yes

Painting See Table III yes

(1)

Coupling with other materials must not cause the "battery effect".

(2)

Coatings free from chromium salts.

(3)

Coatings free of hexavalent chromium.

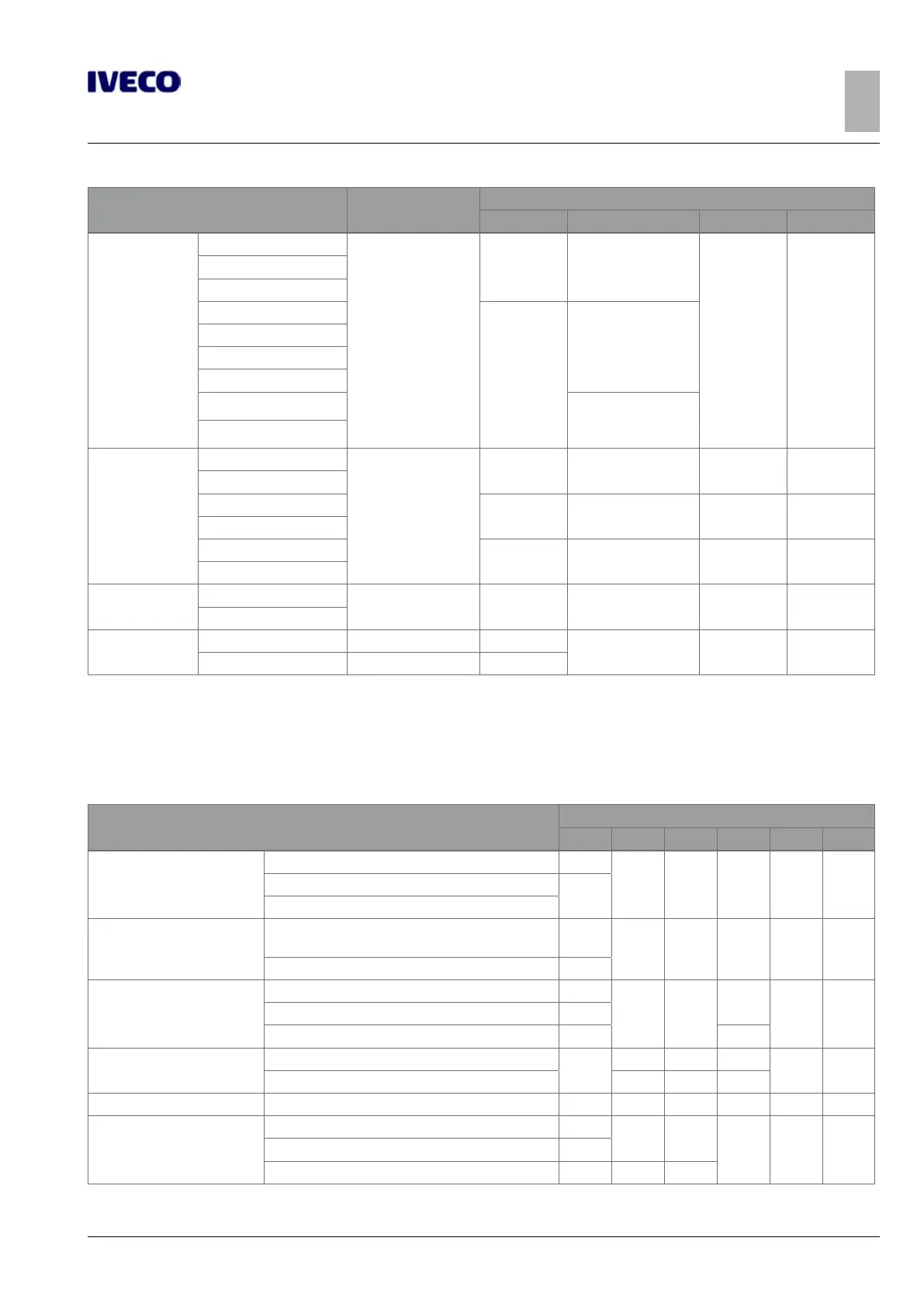

Table 2.6 - Painted parts - IVECO Standard 18 - 1600 (Prospectus III)

Cycle phase description

Classes

A B

(8)

B1

(5)

B2 C D

MECHANICAL SURFACE

CLEANING

(1)

Sand/shot blasting –

yes

(*)

– yes

(*)

yes

(*)

yes

(*)

Brushing

yes

(*)

Sandpapering

PRE-TREATMENT

Iron phosphating

(only for non-precoated ferrous materials)

–

yes

(*)

– yes

(*)

yes

(*)

yes

(*)

Zinc phosphating

(**)

yes

CATAPHORETIC PAINTING

High thickness (30-40 μm)

yes

(2)

yes

(*)

(6)

–

yes

(*)

(6)

yes

(*)

(6) (9)

yes

(*)

(6)

Medium thickness (20-30 μm)

yes

(3)

Acrylic finishing (>35 μm)

– –

RUST PREVENTER

Bi-component (30-40 μm)

–

yes – yes

yes

(*)

(9)

yes

(*)

Single-component (30-40 μm)

– yes –

ANTIROCK PRIMER

Single (130 °C) or bicomponent (30-40 μm)

yes

(3)

– – – – –

VARNISH

Single (130 °C) or bicomponent (30-40 μm)

yes

yes

(*)

–

– yes

(*)

yes

(*)

(7)

Powders (40-110 μm)

yes

(4)

Low temperature single-component (30-40 μm)

– – yes

Loading...

Loading...