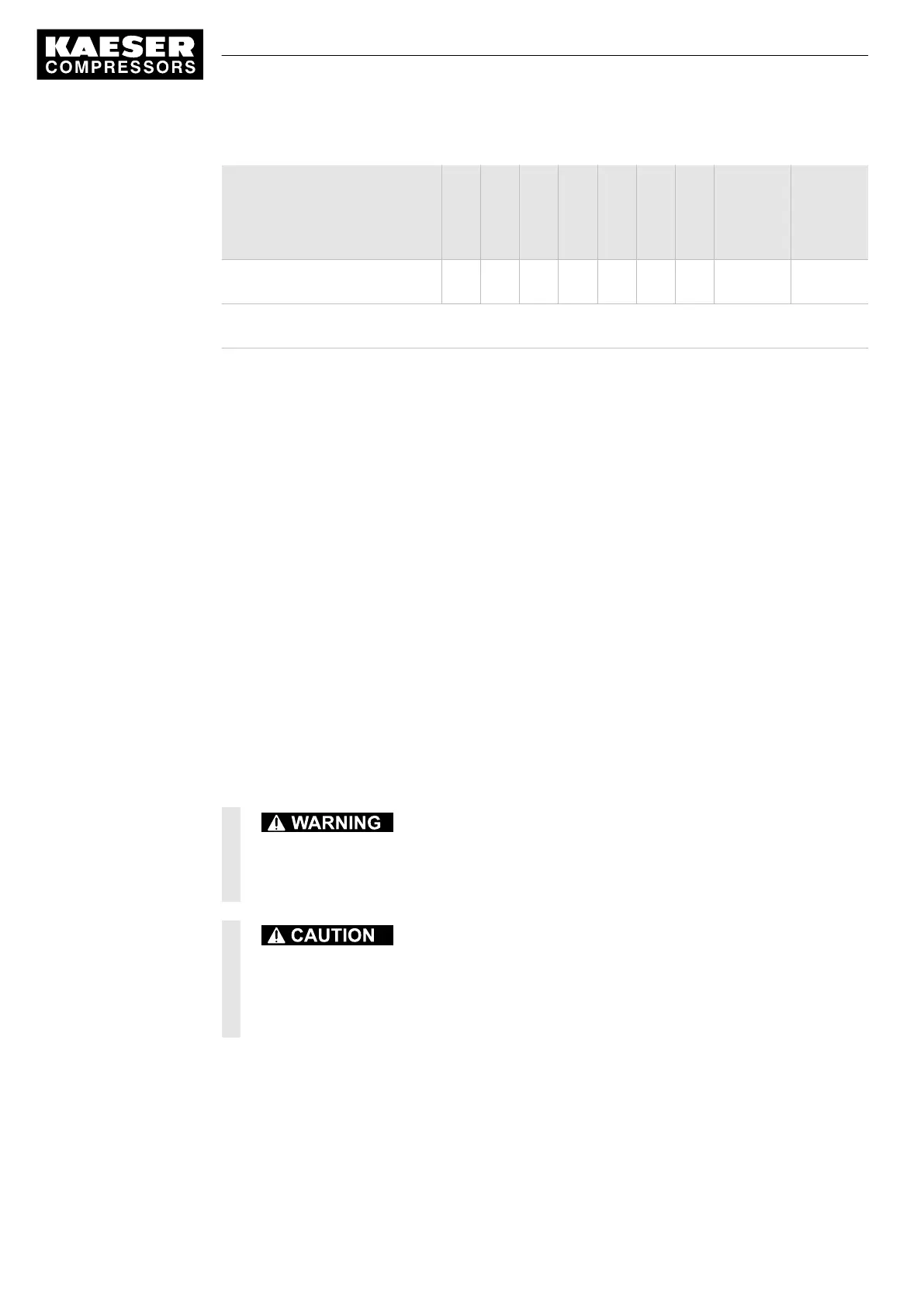

Option:

Function

Daily

A250

A500

A1000

A1500

A2000

A3000

See

chapter

Note

Blow out the spark arrestor with

compressed air.

X

TL-SM = Tool lubricator service manual; EL = refer to an electrician; SW = refer to a specialized

workshop; KS = call KAESER Service.

Tab. 59 Regular maintenance task options

10.3 Engine

➤ Carry out maintenance according to the schedule in chapter 10.2.4.

10.3.1 Cooler maintenance

Material Coolant

Coolant tester

Receptacle

Funnel

Cleaning cloths

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 psig.

Machine cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

The negative cable to the battery is disconnected.

Danger of scalding by hot coolant!

Serious injuries can be caused by hot coolant.

➤ Allow the machine to cool down before opening the enclosure.

There is danger of injury from coolant containing antifreeze!

➤ Avoid eye and skin contact with coolant. If the eyes are affected, rinse immediately with

running water.

➤ Wear protective glasses and gloves.

10 Maintenance

10.3 Engine

70

SERVICE MANUAL Screw Compressor

M26 No.: 9_9446 01 USE

Loading...

Loading...