Summer operation

At outside temperatures above 32 °F it is no longer necessary to inject the control lines in the ma‐

chine with antifreeze before shutting it down.

Further information See chapter 8.3 for frost protector operation.

4.6.3.2 Coolant pre-heating

The engine coolant can be pre-heated to improve cold-starting.

The power supply to the coolant preheater takes place via a separate network connector. A flexible

power cable joins the machine's power plug to the user's power socket.

The coolant pre-heater works according to the principle of self-circulation.

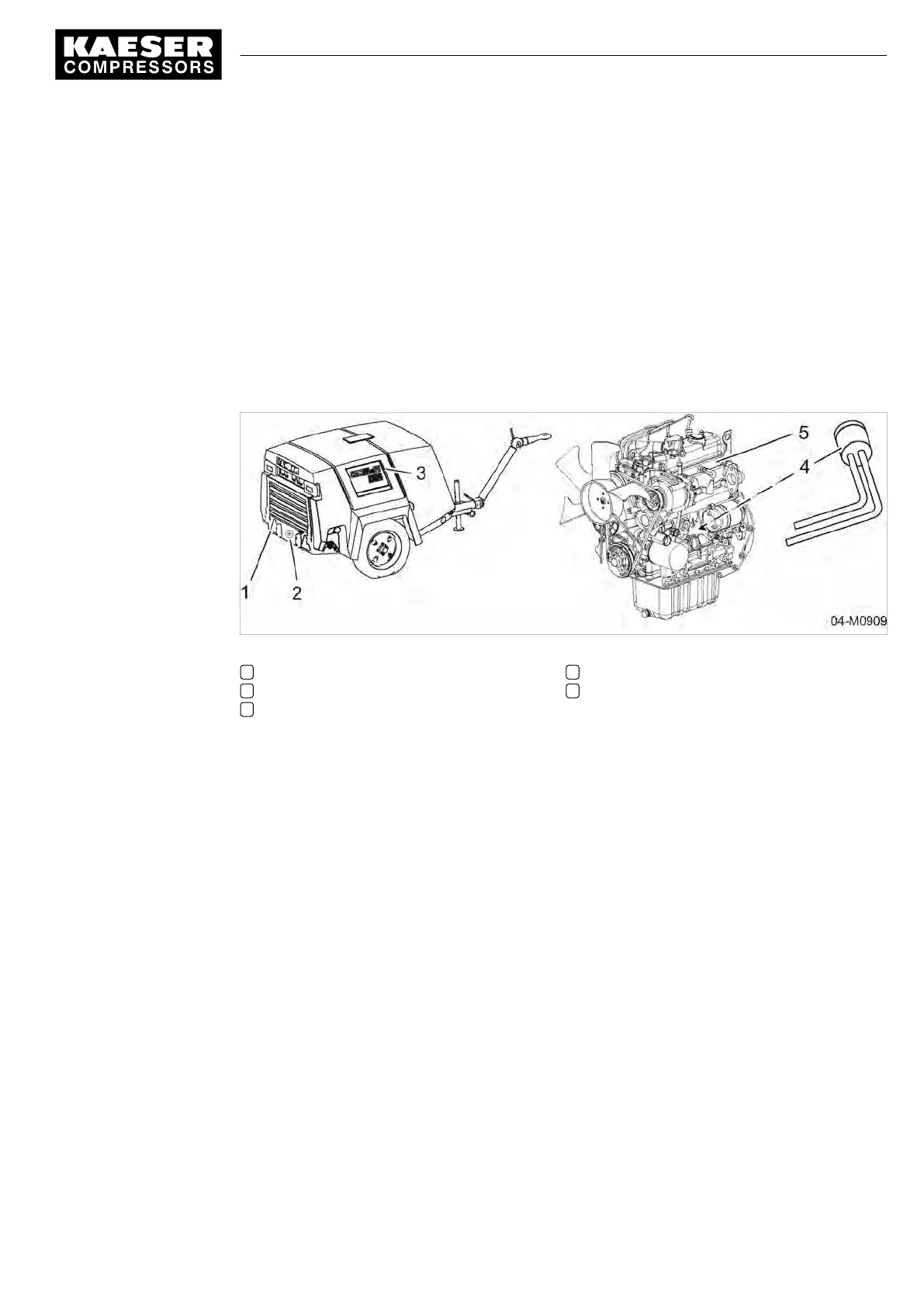

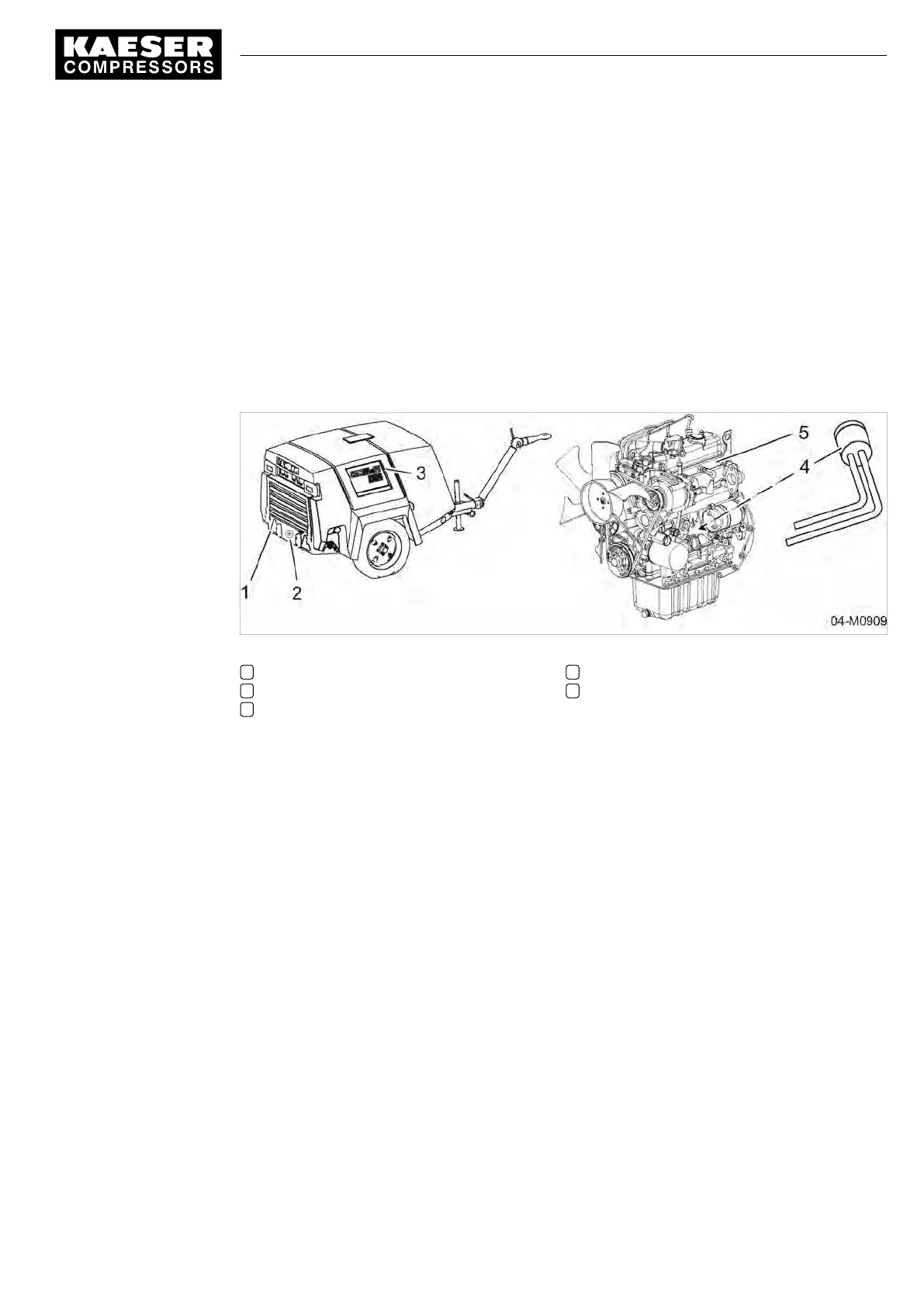

Fig. 7 Coolant pre-heating

1 Bodywork

2 Connecting socket for coolant pre-heating

3 Instrument panel

4 Coolant pre-heating

5 Engine

The ideal coolant pre-heating period is 2-3 hours before the machine is started. A pre-heating peri‐

od of more than 3 hours is not necessary, as the maximum effect has already been achieved within

this period (thermal balance).

Further information Starting the coolant pre-heating (see chapter 8.3).

4.6.4 Option for operating in fire hazard areas

4.6.4.1 Option la

Spark arrestor

A spark arrestor on the exhaust silencer is required when operating a diesel engine in a fire hazard

area and in forestry and agricultural applications. In such applications, a spark may ignite flamma‐

ble materials.

The spark arrestor prevents the exhaust silencer emitting any glowing fuel residue.

Further information See 10.6.3 for spark arrestor cleaning.

4 Design and Function

4.6 Options

No.: 9_9446 01 USE

SERVICE MANUAL Screw Compressor

M26

33

Loading...

Loading...