3.

Checking

the Ele

tr

nic B

ard

The DBS boards and their signal allocations are summarized below. Numbers in parentheses ((1), (2), (3),

and so on) indicate pin numbers, and a checkmark

(

)

indicates a point that should be checked, if possible.

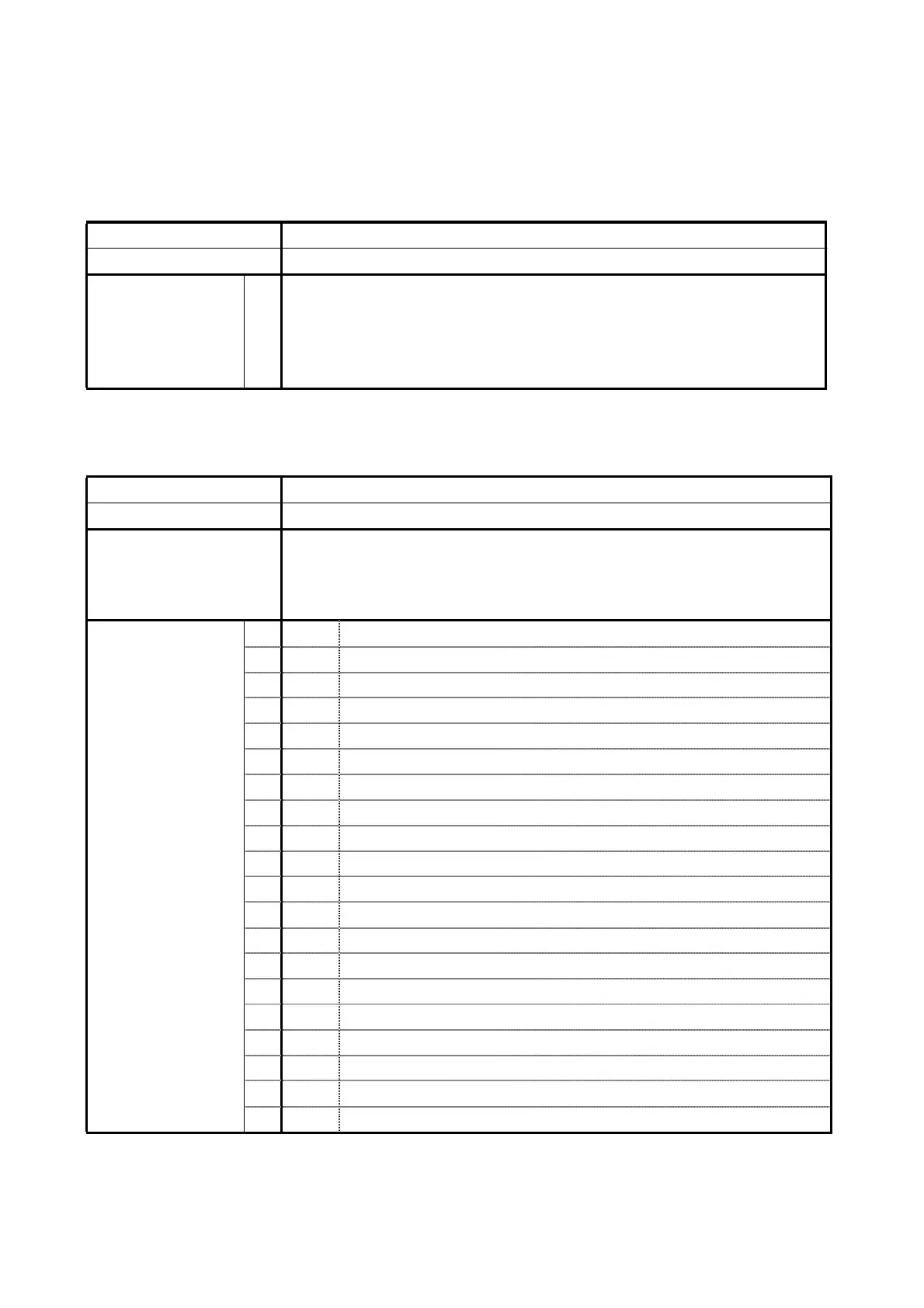

3.1 M

in Bo

d Assembl

B2)

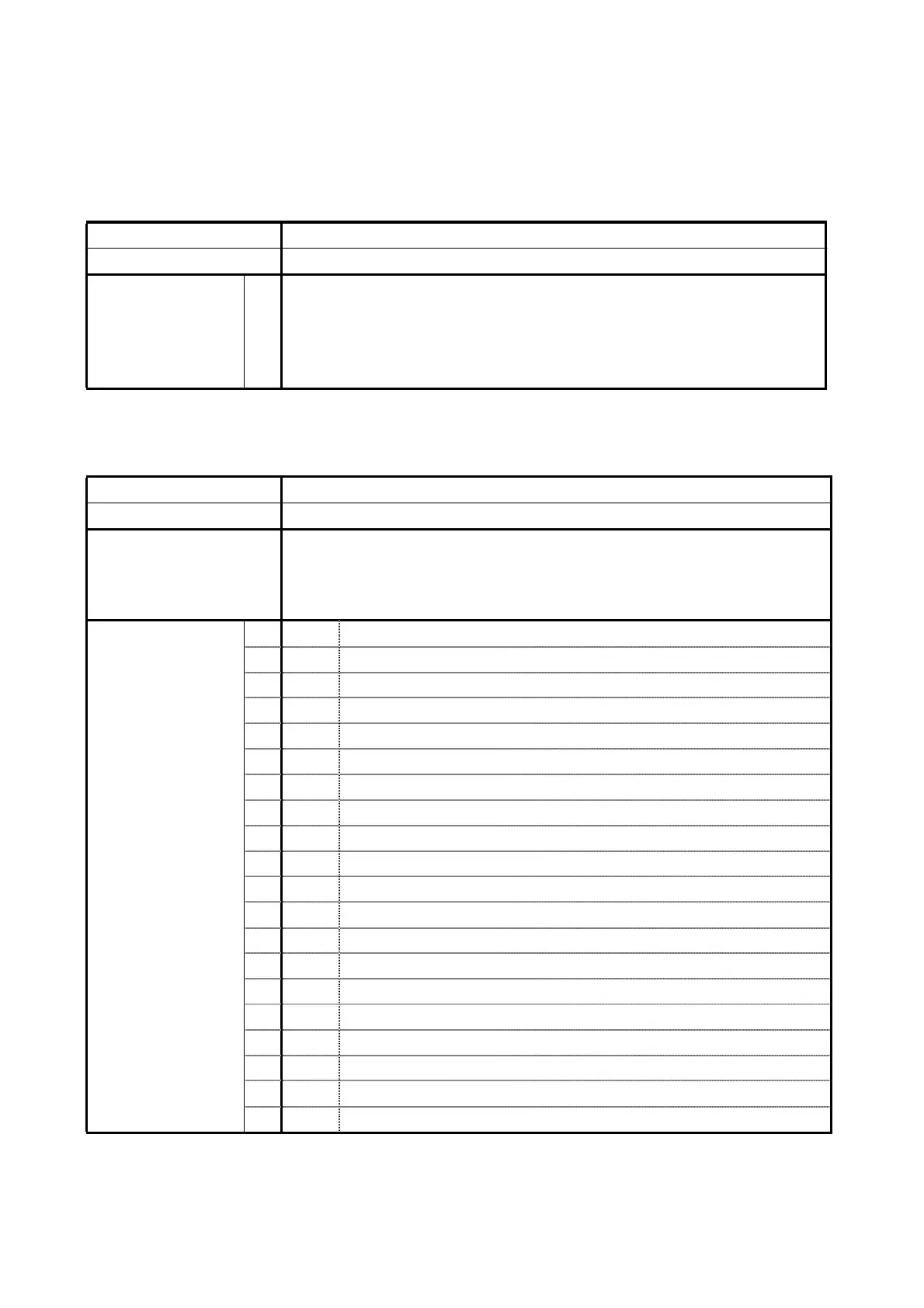

3.2 An

l

g Bo

d Assembl

B

)

generator circuit

ASSY P/N 321-64556-14 (same for all models)

Board P/N 321-64558

Circuits Mounted

Mechanical sensor PID control (feedback) circuit

Measurement system (A/D converter) circuit and reference power supply

Magnet temperature correction and measurement circuits

Voltage for Checking

(when

connected

to

detector

assy)

TPG Signal ground (0 V)

TP1 During pre-amp control signal output feedback: 0 V

TP2 Coil current control voltage

TP3 Voltage on output resistance end (about 0.6 to 2.3 V)

J2 (1) Beam sensor LED positive potential about -5.2 V

J2 (2) Beam sensor LED negative potential about -6.8 V

J2 (3) Magnet temperature sensor output voltage about 0.6 V

J2 (4) Signal ground (0 V)

J2 (5) During beam sensor photodiode output feedback: 0 V

J2 (6) Signal ground (0 V)

J2 (7) During beam sensor photodiode output feedback: 0 V

J1 (1) Signal ground (0 V)

J1 (2) Power supply for analog system: about -12 V

J1 (3) Power supply for analog system: about +12 V

J1 (4) Temperature A/D digital signal

J1 (5) Temperature A/D digital signal

J1 (6) Weight A/D digital signal

J1 (7) Weight A/D digital signal

J1 (8) Weight A/D digital signal

J1 (9) Weight A/D digital signal

ASSY P/N 321-71373-41 (same for all models)

Board P/N 321-71372

Circuits Mounted

CPU (calculates measurement data and controls key switches)

Dedicated LCD driver IC chip

EEPROM with connector J3 for writing with Flash Writer

Main clock (20 MHz), used to form a +5 V logic system

Dedicated calendar IC chip

38 DBS-SH-e-1210

Loading...

Loading...