8.

rouble

ho

tin

8.1

e

e

l

ect

e Measu

es

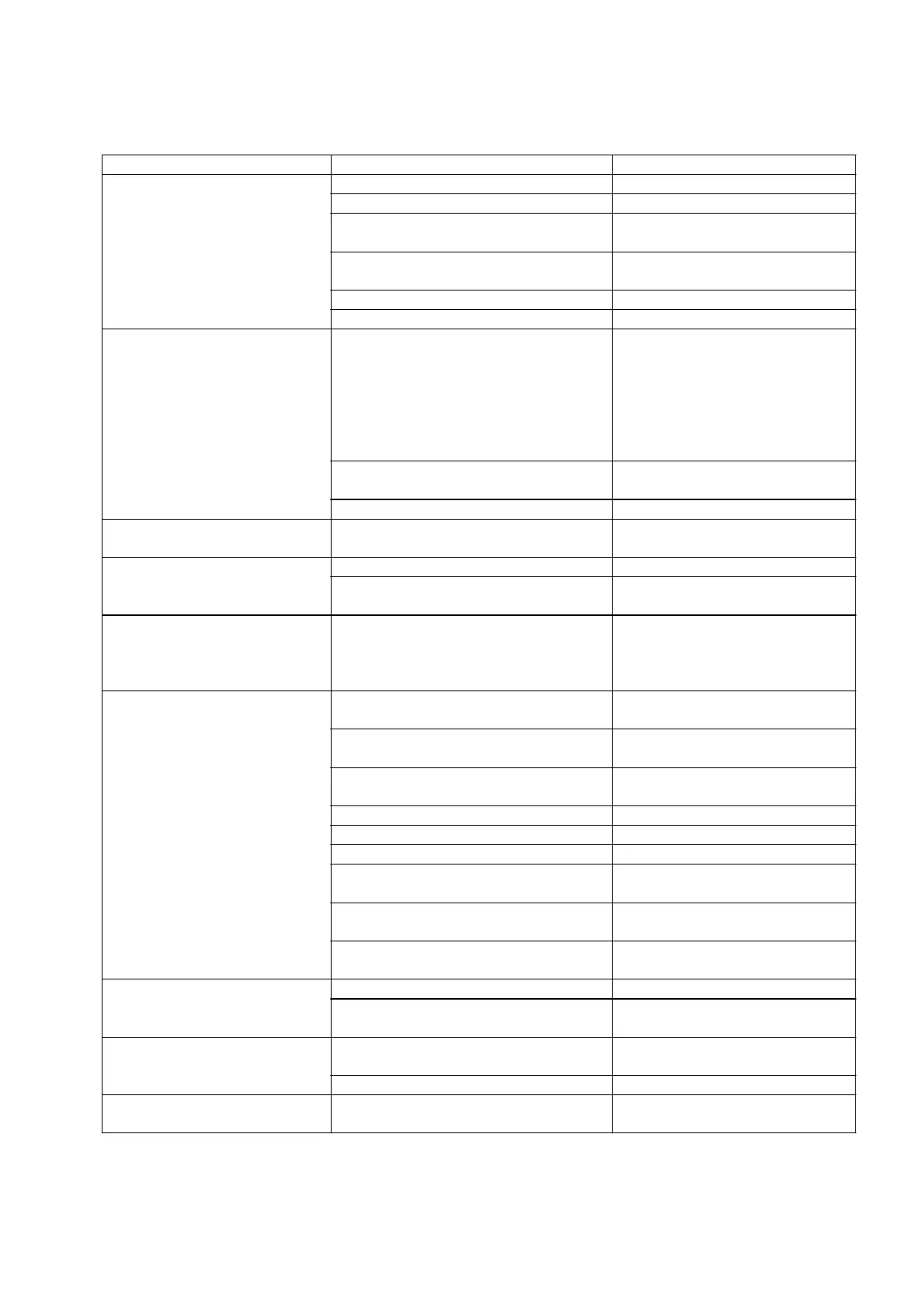

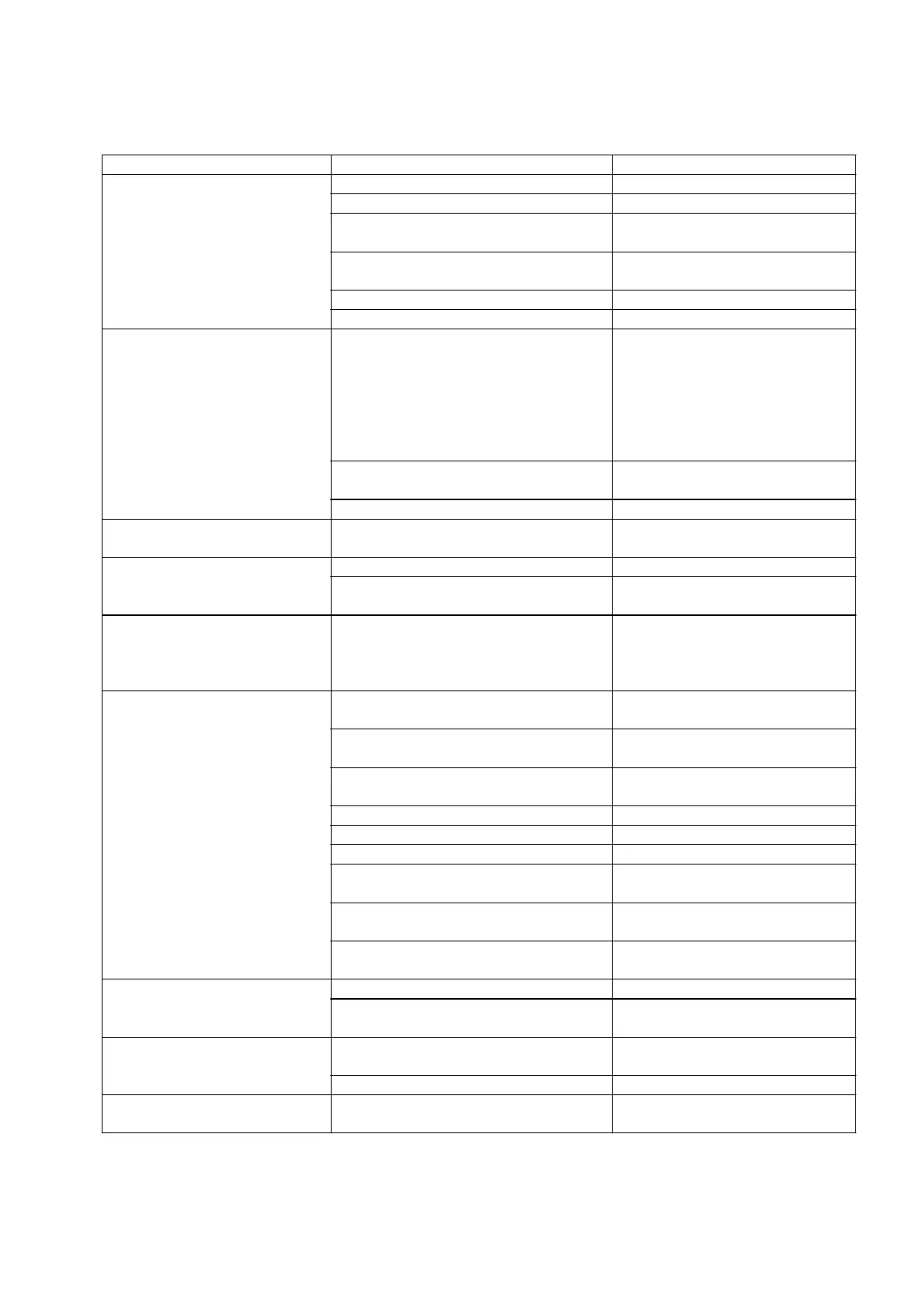

Problem Cause Solution

Nothing appears on the display.

1) Power supply voltage is lower than rating. Check the power supply voltage.

2) Defective power cord (S17) Replace the power cord (S17).

3) Defective power board assembly (B4)

Replace the power board assembly

(B4).

4) Defective main board assembly (B2)

Replace the main board assembly

(B2).

5) Defective power supply inlet (B11)

Replace the

power supply

inlet

(B11).

6) Blown fuse (S18) Replace the fuse (S18).

Display does not change from

“CHK” display after turning on the

power.

1) Improper cable alignment of the

unit assembly (1)

Re-clamp the cable of the unit

assembly (1)with proper alignment.

(Fig.27)

Re-clamp the Cable and the Ferrite

core of the unit assembly (1) not

touch the detector assembly (U11)

(Fig.23)

2) Defective Pt-Ni band (U17)

Check the Pt-Ni band (U17) and

reconnect it properly.

3) Damaged OPF (U1) Replace the unit assembly (1).

Part of displayed numbers or

symbols does not appear.

1) Defective main board assembly (B2)

Replace the main board assembly

(B2).

Keys do not function.

1)

Defective

main

board

assembly

(B2)

Replace the main board assembly (B2).

2 ) Case as sembl y ( S2) is not f aste ned

properly.

Refasten the case assembly (S2).

Password was forgotten.

-

Input 9999 as password , and press

“←”key and “ENTER” key for 3

seconds at the same time. The

password can be set to 9999.

"OL" or "-OL" is displayed.

1) Stopper plate (U14) is hitting the stabilizer

pin.

Reposition the stopper plate (U14).

2) Defective Pt-Ni band (U17)

Check the Pt-Ni band (U17) and

reconnect it properly.

3) Force coil assembly (L1) is hi

t

t

t

ing the

magnet assembly (U9).

Reattach or replace the force coil

assembly (L1).

4) Defective force coil assembly (L1) Replace the force coil assembly (L1).

5) Damaged OPF (U1) Replace the unit assembly (1).

6) Defective detector assembly (U11)

Replace the detector assembly

(U11).

7) Defective analog board assembly (B3)

Replace the analog board assembly

(B3).

8) Corrupt EEPROM data

Initialize all NVRAM data (6.5), and

download data (6.4).

9) Overweight sample or calibration weight is

on the pan.

Remove the sample or weight.

Zero-drift or span-drift is large.

1) Warmup time is inadequate. Warm up the system.

2) Instrument is exposed to direct sunlight or

draft from a heater, cooler, etc.

Change the installation location.

Span is incorrect.

1) Instrument is not leveled.

Level the instrument using the level

adjusters (B6).

2) Damaged OPF (U1) Replace the unit assembly (1)

Cornerload error is large. (30 d or

more)

1) Damaged OPF (U1)

Replace the unit assembly (1) and

make readjustment.

DBS-SH-e-1210 55

Loading...

Loading...