- 17 -

INSTALLATION

2. TD TANK INSTALLATION CONDITIONS

Satisfy the following installation conditions.

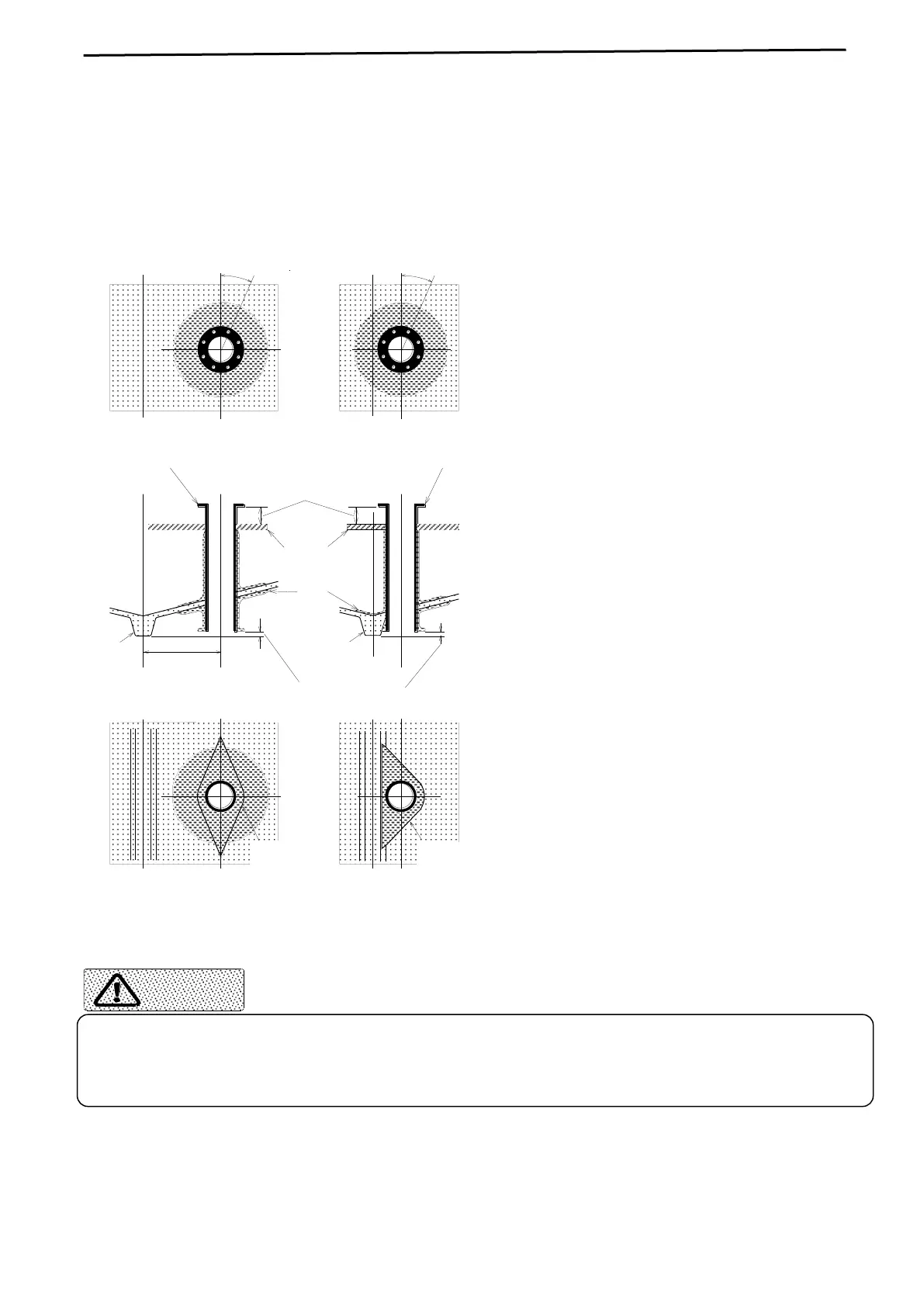

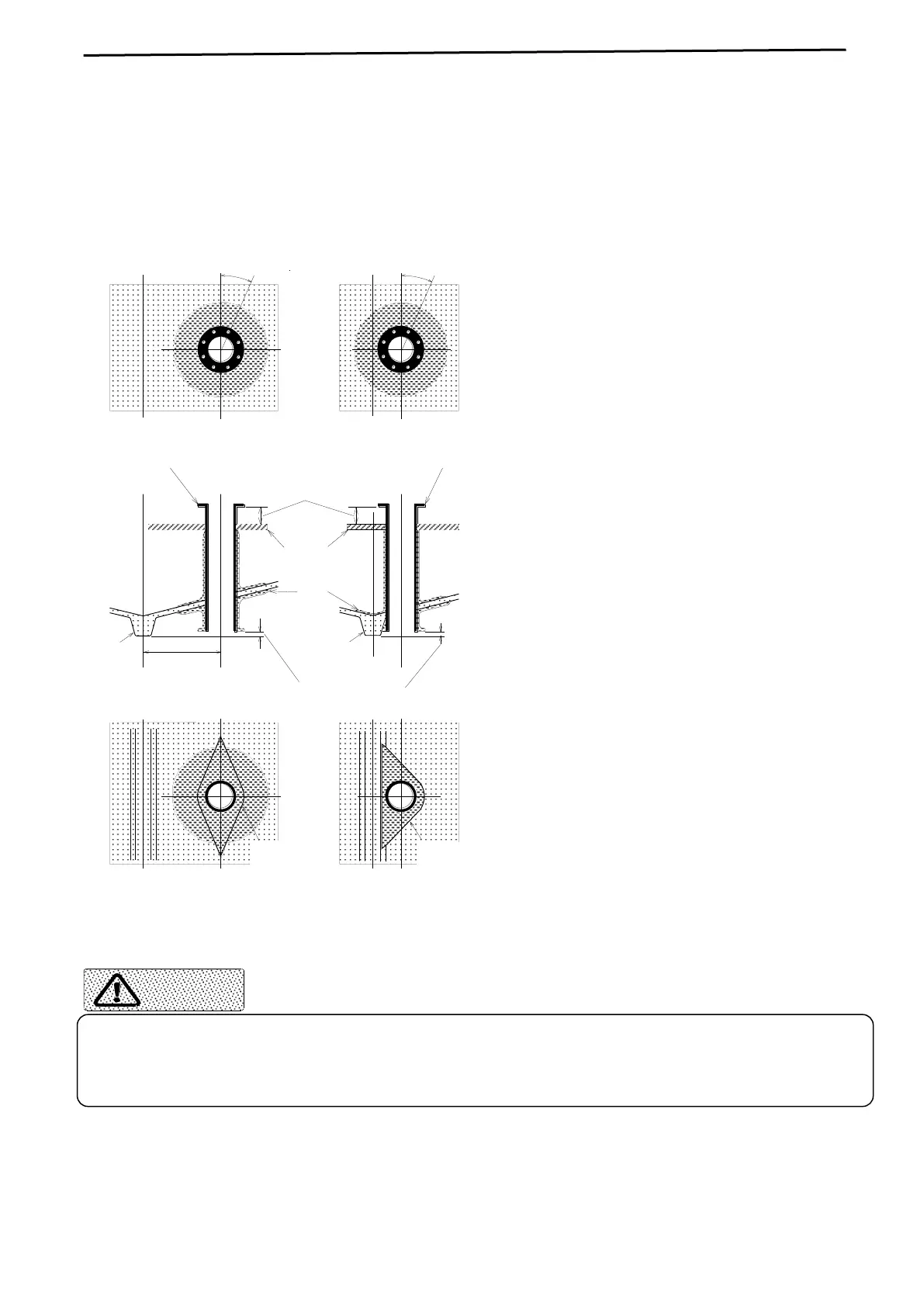

- Installation point should be 1/3 to 1/2 of the ship’s overall length back from the bow.

- If it cannot be installed on the keel, the center of the TD tank should be within 1 meter of

the keel.

Fully discuss about the strength and water tightness with the ship owner, the engineer in the

shipyard, and the installer before determining on the position, the method of installation, and

necessary materials. Otherwise it causes maritime accidents.

22.5°

KEEL

MAX 1MT

TRUNK PIPE

22.5°

STREAMLINING

BOARD

KEEL

VIBRATION SUPPORT

Not to protrude lower than Keel.

TRUNK PIPE

STREAMLINING

BOARD

FRP

FLANGE HOLE ANGLE

Space under Flange

-There should be no obstacles right below

the flange to avoid hindering bolt clamping.

-Do not protrude the TD tank from

beneath the keel.

-Flange should be positioned in parallel

with the ship’s draft and over the draft at

full load.

-Apply FRP sufficiently to all the necessary

sections to prevent water leakage.

-Make the surrounding of TD tank in a

streamline shape and provide a fairing

plate to suppress water resistance and

generation of air bubbles to the minimum.

-Attach a fin if necessary.

Make sure the fin does not hinder bolt

clamping for Flange.

Loading...

Loading...