Device description

Leuze electronic GmbH + Co. KG BPS 348i 23

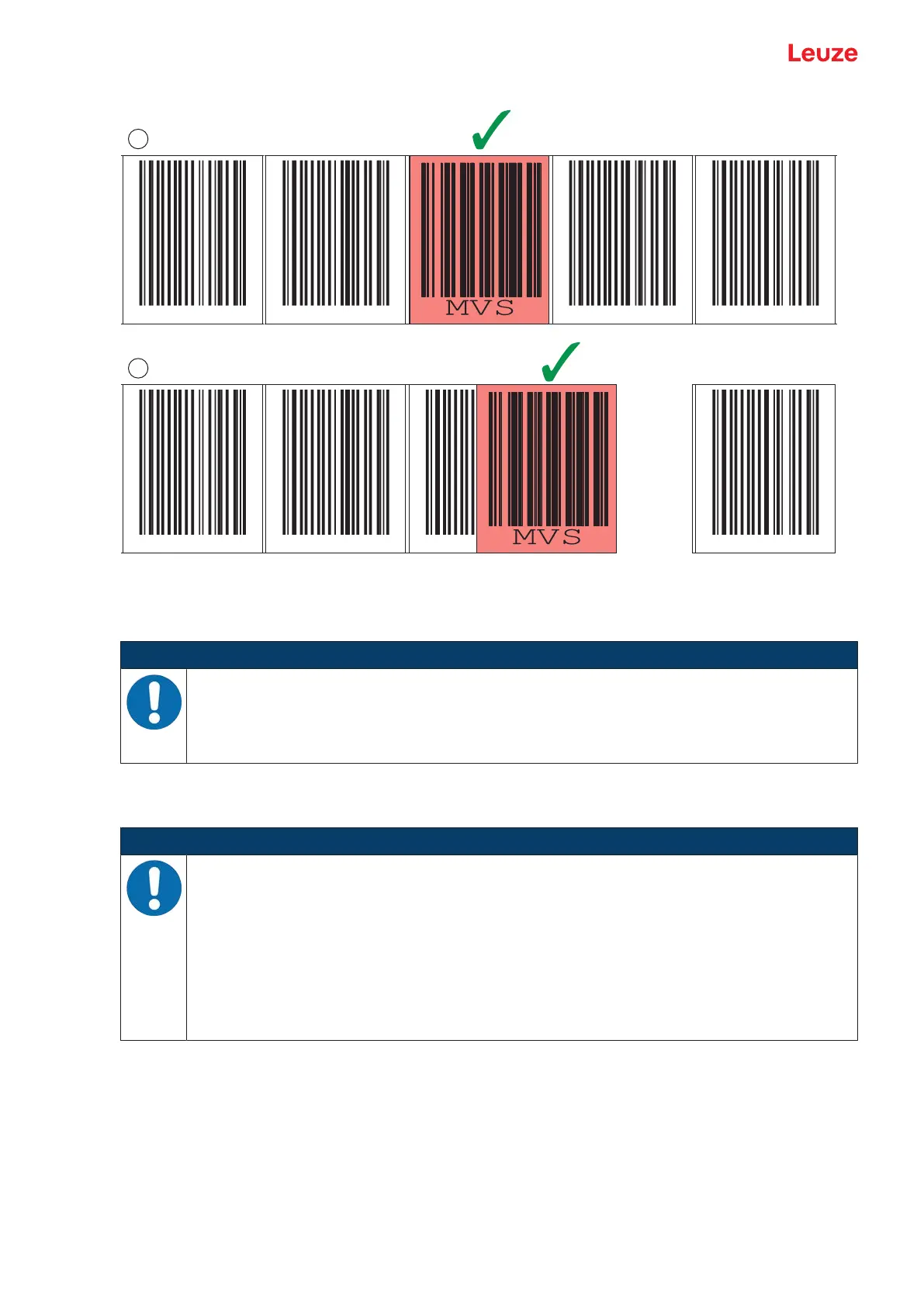

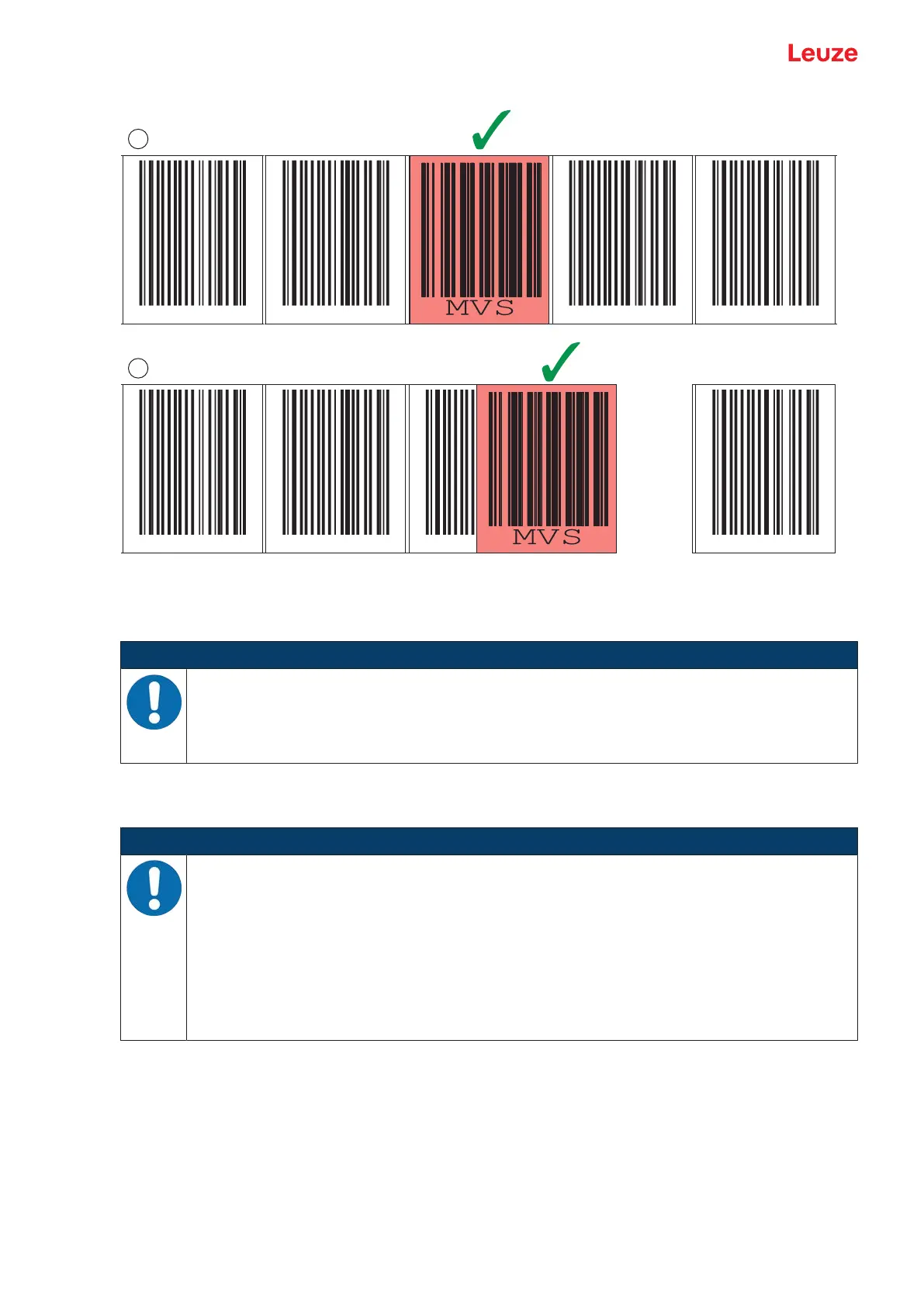

1

2

000040 000044 000048 015000 015004

000040 000044 000048 015004

G40Leuze

G40Leuze G40Leuze G40Leuze G40Leuze G40Leuze

G40Leuze G40LeuzeLeuze G40Leuze

1 Control barcode perfectly affixed on the barcode tape

2 Control bar code at small gap between two barcode tapes

Fig.3.14: Correct positioning of the control bar code

NOTICE

Gaps in barcode tape!

Ä Avoid polished and high-gloss surfaces.

Ä Keep the gaps between the two barcode tapes and the control barcode as small as possi-

ble.

Measurement value switching between two barcode tapes with different value ranges

The MVS or MV0 control barcode is used to switch between two barcode tapes.

NOTICE

1m difference in the bar code position values for correct measurement value switching!

Ä For different BCB value ranges, make certain that the position value has a value distance of

minimum 1m between the preceding position bar code (before the control bar code) and the

subsequent position bar code (after the control bar code).

If the minimum distance between the barcode values is not maintained, position determina-

tion may be faulty.

ð Example (BCB with 40mm grid): If the last position barcode on the BCB before the control

barcode is 75120, the following position barcode on the BCB after the control barcode

must be at least 75220.

• The end of the preceding bar code tape and the start of the subsequent bar code tape can end and be-

gin, respectively, with completely different position bar codes.

• Position value changeover by means of a control bar code always occurs at the same position, i.e., it

serves to change from the preceding tape to the subsequent tape and vice versa.

• If the center of the BPS reaches the transition point of the control barcode, the device switches to the

second BCB, provided the next position label is in the BPS's scanning beam.

The output position value is thereby always uniquely assigned to one BCB.

Loading...

Loading...