MAINTENANCE/SERVICE

Traction Drive: Dual-Speed Linkage

See

·Speed Range Contror

in

Operator's Station section for lever operation details. Following is

troubleshooting and adjustment information on the

duaJ

·speed linkage:

PROBLEM: Lever

does

not stay

in

low (field speed) rang

e,

but

is

OK

in high (road speed) range.

POSSIBLE CAUSES:

• Loose cable. See Adjustment #1.

• Lever

hits

console before cam hits stop

bolt

(

A)

. See Adjustment

#2

.

•

Le

ver travel n

ot

obstructed. motor linkage requires adjustment. See Adjustment

#3

& 4.

PROBLEM:

Lever

does not stay

in

high range.

POSSIBLE CAUSES:

• Loose cable. See Adjustment #1.

• Motor linkage requires adjustment. See Adjustment

#3

&

4.

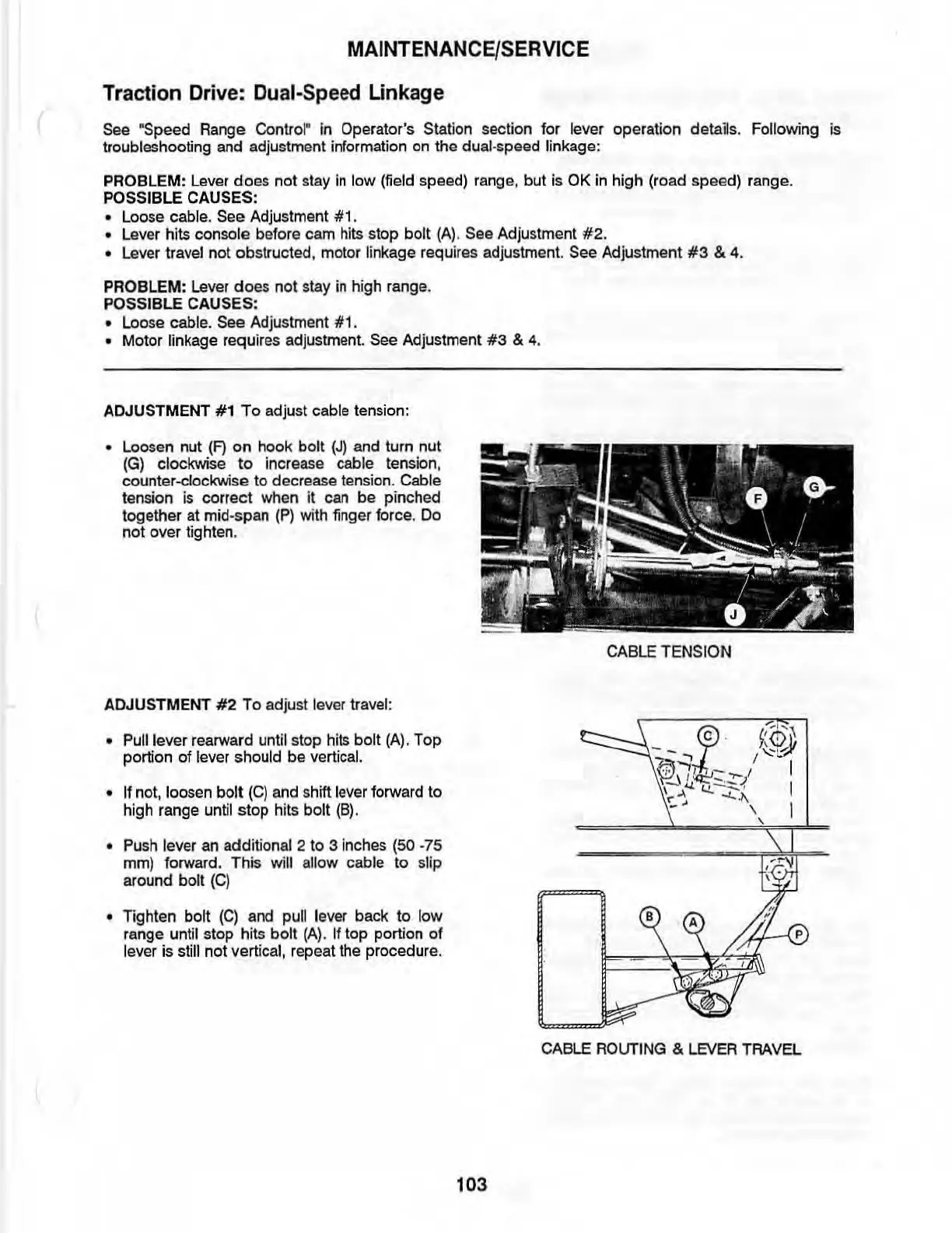

ADJUSTMENT

#1

To

adjust cable tension:

• Loosen nut

(F)

on

hook bolt

(J

) and turn nut

(G)

clockwise

to

increase cable tensi

on.

counter-clockwise to decrease tension. Cable

tension is correct when it can

be

pinched

together at

mid·span

(P

) with fi

ng

er force. Do

not over tighten.

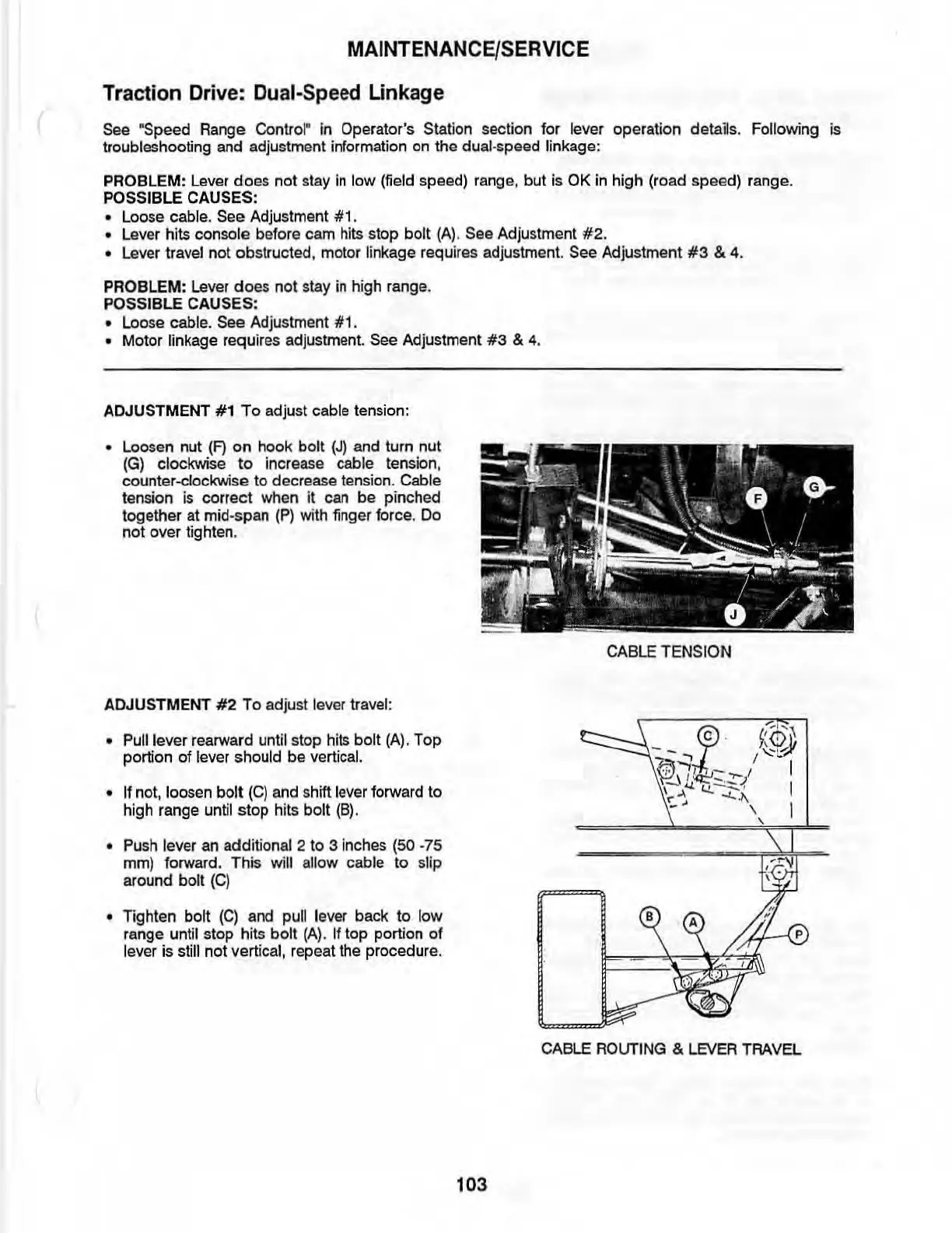

ADJUSTMENT

#2

To adjust lever travel:

• Pull lever rearward until stop hits bolt

(A)

. Top

portion

of

lever shoUld

be

vertical.

• If

not, loosen

bolt

(C)

and shift lever forward to

high range until

st

op hits

bolt

(8)

.

•

Pu

sh lever an additional 2 to 3 inches

(SO

·75

mm) forward. This will allow cable

to

slip

around

bolt

(C)

• Tighten bolt (C) and pull lever back to l

ow

range Until st

op

hits

bolt

(A).

If

top portion

of

lever is still not vertical, repeat the procedure.

103

CABLE

TENS

I

ON

CAB

LE

ROUTING

&

LEVER

TRAVEL

Loading...

Loading...