MAINTENANCE/SERVICE

Header Drive: Hydraulics

FLOW

COmRQL

BlOCK

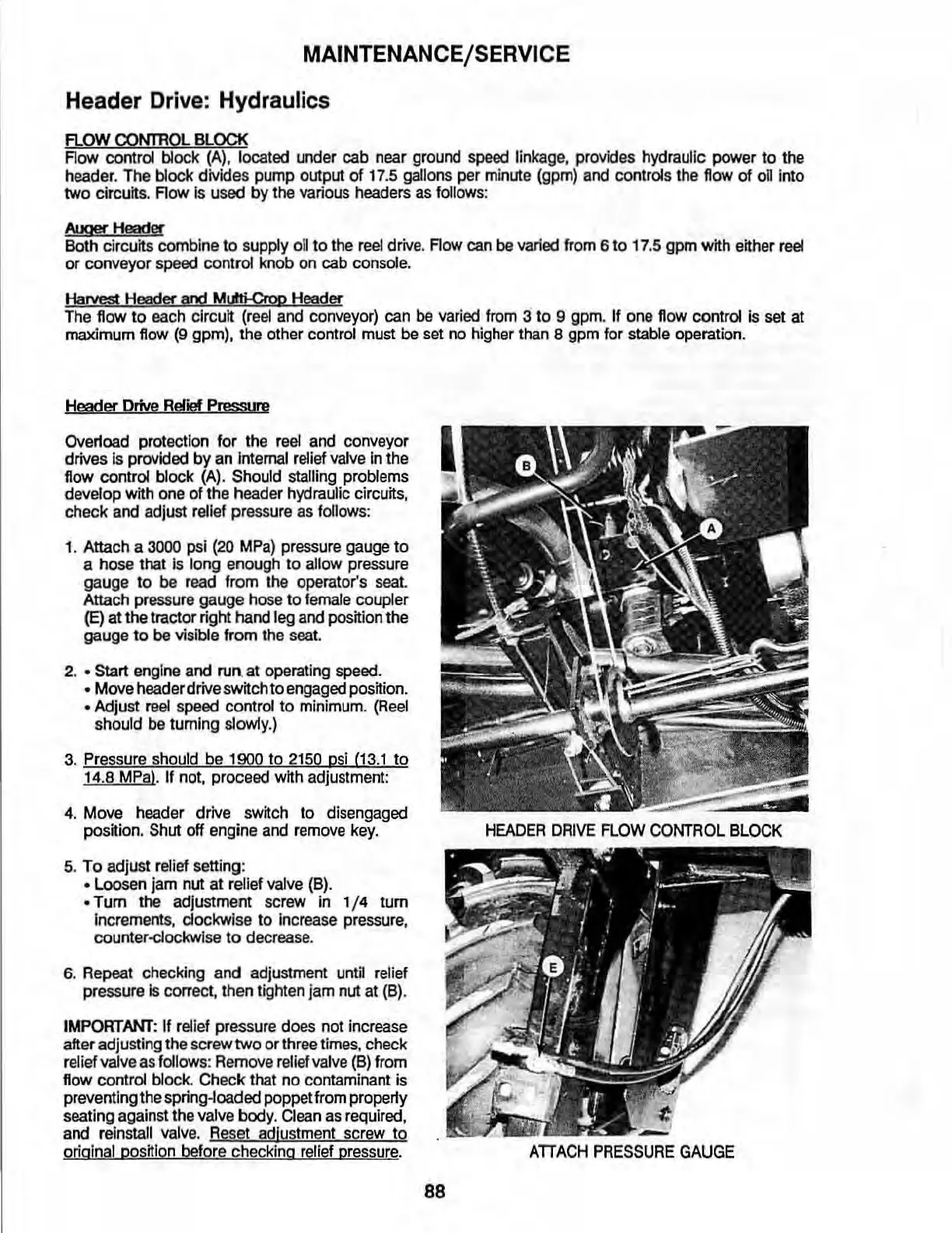

Row control block (Al.

located

under cab near ground

speed

linkage, provides hydraulic power to the

header.

The

block dMdes pump output

of

17

.5 gallons per minute (gpm)

and

controls the

flow

of

on

into

two circuits.

Row

Is

used

by

the various headers

as

follows:

AlxmHeader

Both circuits combine

to

supply

oil

to the

reel

drive. Row

can

be

varied from 6 to

17

.5 gpm with either

reel

or

conveyor speed control knob on cab console.

Harm;!

Header

and

MIIti-Croo

Header

The

flow

to

each circuit

(r

eel

and conveyor) can

be

varied from 3

to

9 9pm. If one flow control

Is

set at

maximum flow

(9

gpm), the other control must be

set

no

higher than 8 gpm for stable operation.

Head

...

OrNe

Relief

Pressure

Overtoad protection for the

reel

and conveyor

drives

Is

provided by

an

internal relief

valve

in

the

flow control block

(A)

. Should stalling problems

develop with

one

of the header hydraulic circuits,

check

and

adjust relief pre

ss

ure

as

follows:

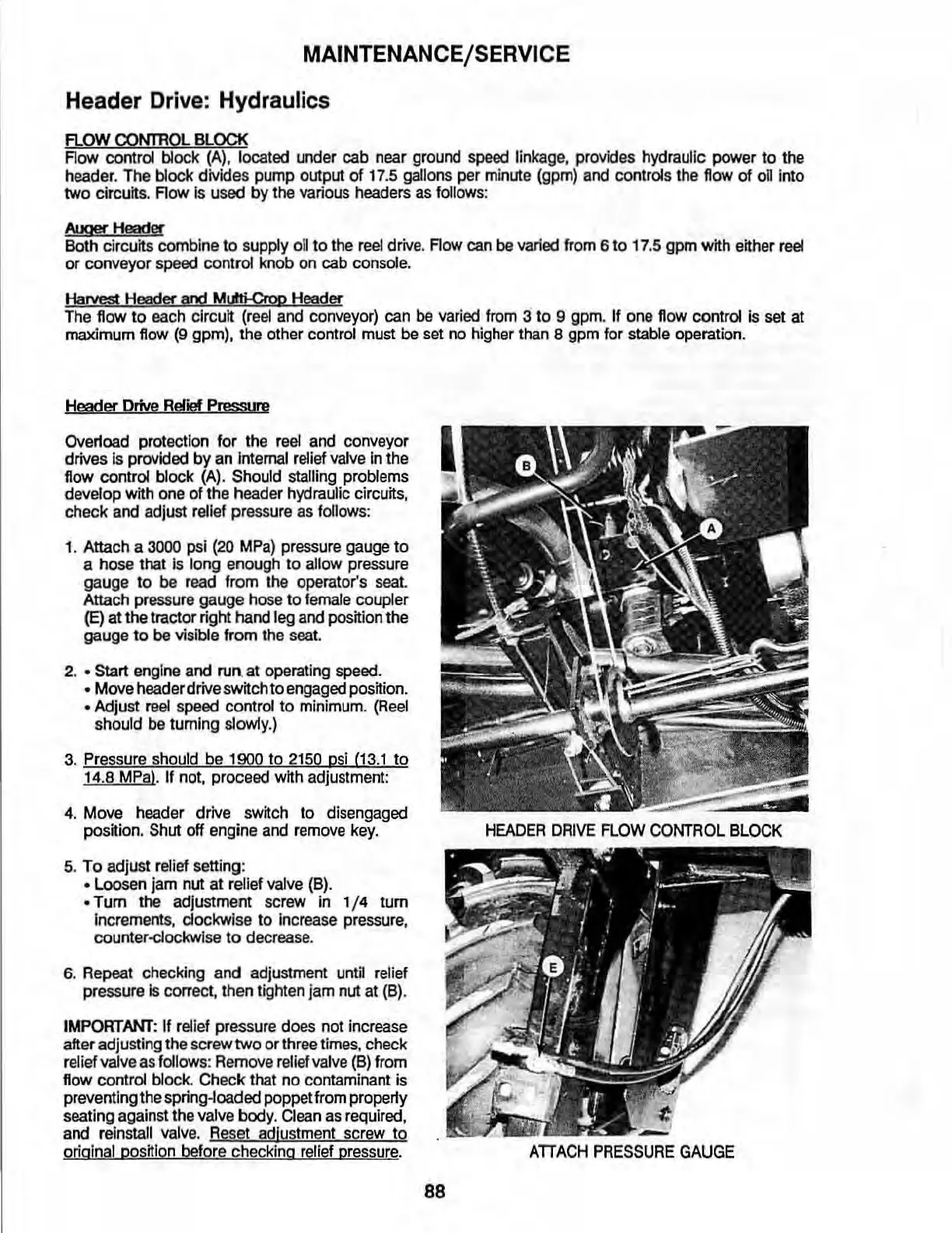

1. Attach a

3000

psi

(20

MPa)

pr

essu

re

gauge to

a hose

that is long enough to allow pr

essu

re

gauge to

be

read from

the

operator's

seat.

Attach pressure gauge hose to

female

coupler

(E)

at the tractor right hand leg

and

position

the

gauge

to

be

visible from the

seat.

2 . • Start engine and

run.

at operating

speed.

• Move header drive switch to engaged position.

• Adjust reel

speed

control to minimum.

(Reel

should

be

tuming

slow1y

.)

3.

Pres

sure

should

be

1900

to

2150

psi

(13.1 to

14

.8

MP

a).

If not, proceed with adjustment:

4.

Move header drive switch to disengaged

position.

Shut off engine

and

remove

key.

5.

To adjust relief setting:

• Loosen jam nut at relief

valve

(8).

• Tum the adjustment screw

in

1/ 4 tum

increments. clockwl

se

to inc

rease

pre

ssu

re

,

counter-dockw

ise

to

decrease.

6. Repeat checking and adjustment until

relief

pressurels correct, then tighten jam

nut

at

(6).

IMPORTANT:

If

rel

ief pressure d

oes

no

t increase

after adjusting the screw two or three

times,

check

relief valve

as

fol

lows: Remove relief

valve

(8) from

flow control block. Check that no contaminant

is

preventing the spring-loaded poppet from properly

seating against the valve

body.

Clean

as

required,

and reinstall

valve

.

Re

se

t adlustment screw to

original position before checking

relief pressure.

HEADER

DRIVE

FLOW

COmROL

BLOCK

ATIACH

PRESSURE

GAUGE

88

Loading...

Loading...