OPERATION

Attaching the Header

NOTE:

For

Ha

rvest Headers with gauge

wheels,

in

structions under "Attaching" and

"Oetaching the H

eader"

which refer to the

"header stand" do not apply. U

se

the "stand"

position of the gauge

wheels

to support rear of

header.

All

gauge

wheel

positio

ns

are

identified

on a decal located at each gauge wheel. Be

sure to reposition

gauge

whee

l to

field

position

before operating.

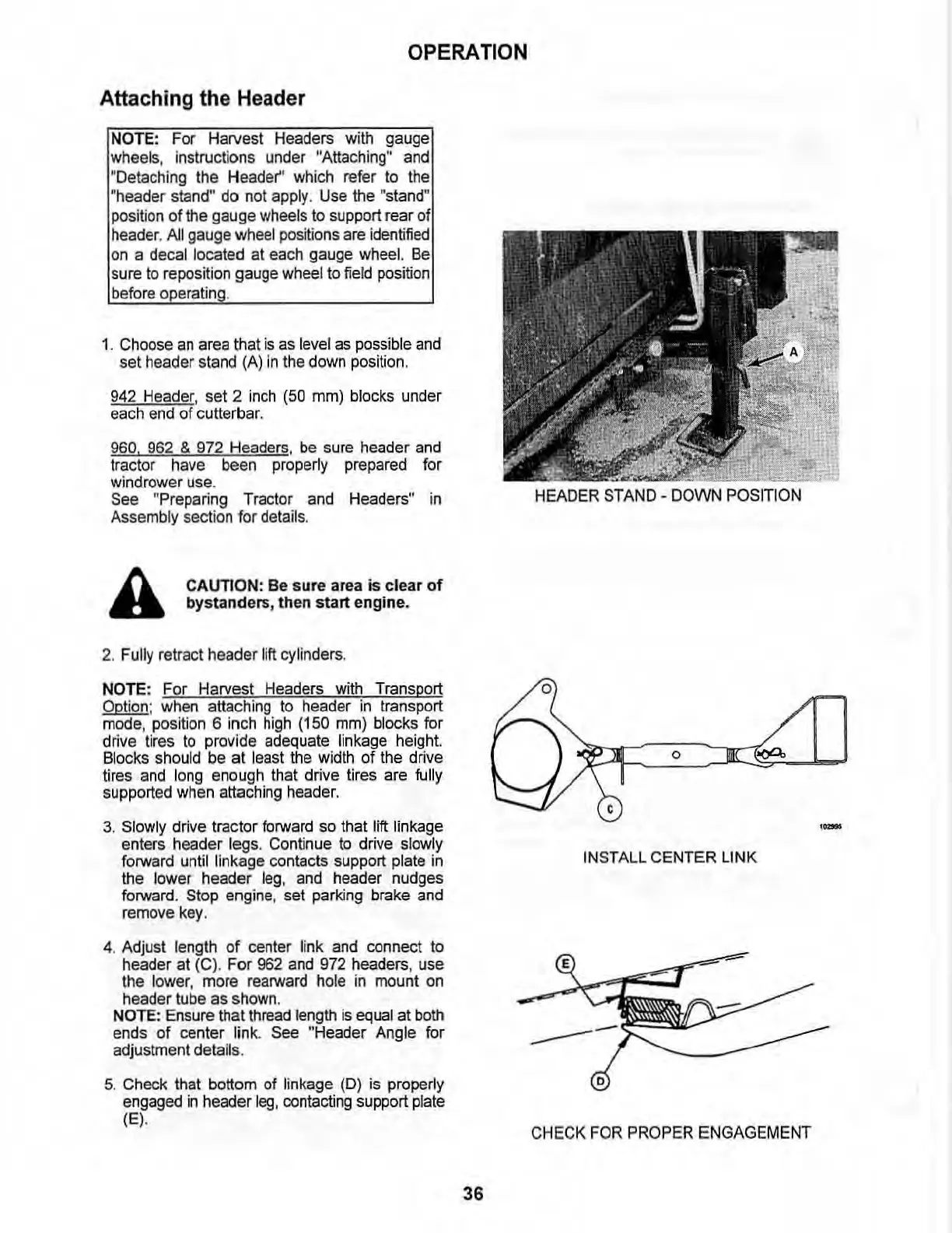

1.

Choose

an

area

that

is

as

level

as

possible

and

set

header stand (

A)

in

the down position.

942

He

ader, set 2

inch

(50

mm) blocks under

each

end

of cutterbar.

960.

962

&

972

Headers, be sure header

and

tractor

have

been

properly

prepared

for

wind

rower

use

.

See

"Preparing T

ractor

and

Headers" in

Assembly secti

on

for

details.

A

CAUTION:

Be

sure

area is clear

of

bystanders

, then

start

engine.

2. Fully retract header lift cylinders.

NOTE: For Harvest Headers with Transport

Opti

on

: when attaching

to

header

in

transport

mode, position 6 inch

high

(150 mm) blocks for

drive tires

to

provide adequate linkage height.

Blocks should be at least the width of the drive

tires

and

long enough that drive tires are fully

supported when attaching header.

3. Slowly drive tractor forward so that

Jift

linkage

enters header legs. Continue

to

drive slowly

forward until linkage contacts support plate

in

the lower header

leg

,

and

header nudges

forward. Stop engine, set parking brake

and

remove key.

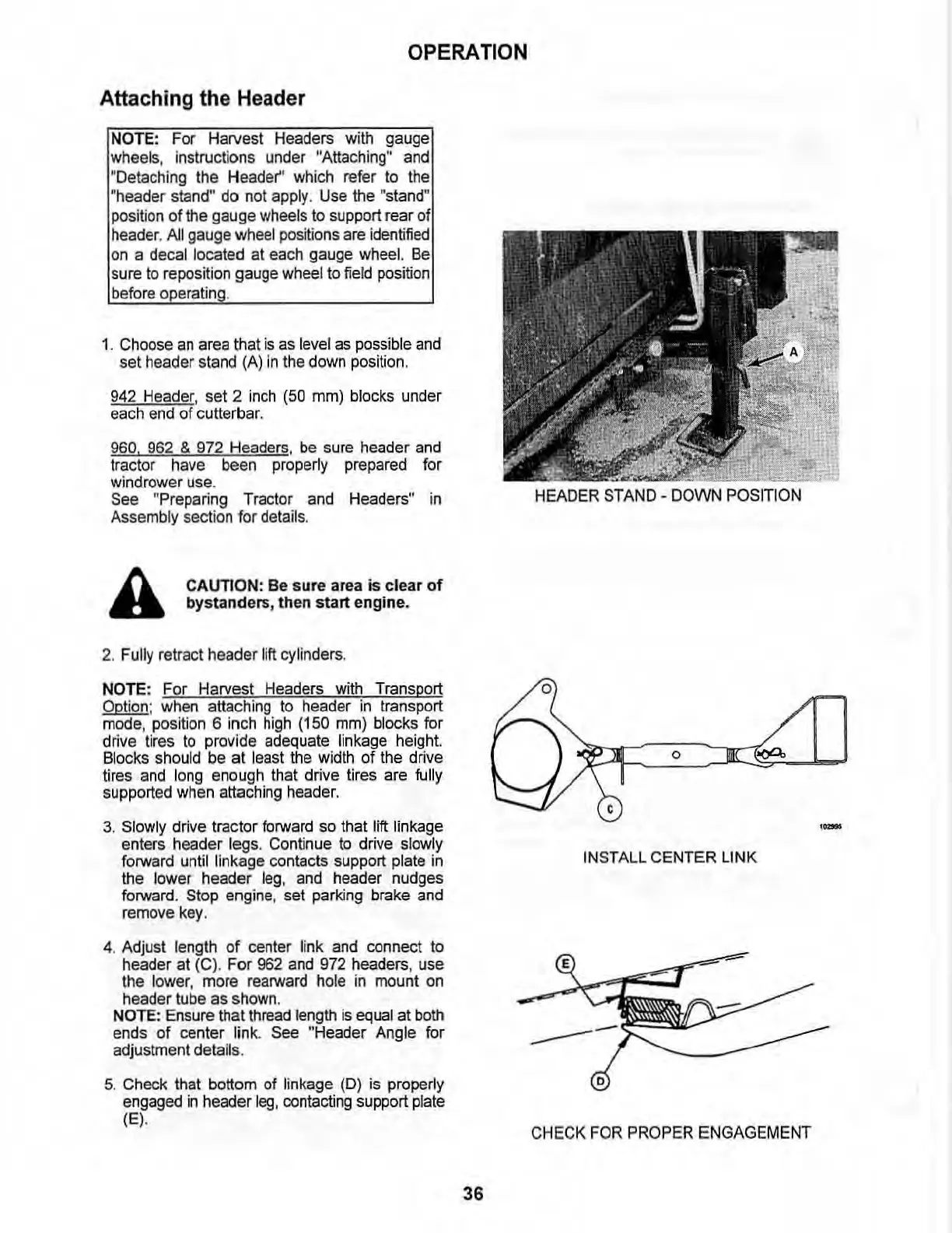

4. Adjust length

of

center link

and

connect to

header at (C). For

962

and 972 headers, use

the lower, more rearward hole

in

mount on

header tube as shown.

NOTE

: Ensure that thread length

is

equal at both

ends

of

center l

in

k.

See

"Header Angle for

adjustment details.

5. Check that bottom of linkage (D)

is

proper1y

engaged

in

header

leg,

contacting support plate

(EI

·

36

HEADER

STAND

-

DOWN

POSITION

o

o

c

IN

STALL

CEN

TER LINK

C

HECK

FOR

PROPER

ENGAGEMENT

Loading...

Loading...