(

\

MAINTENANCE/SERVICE

Fuels, Fluids and Lubricants (continued)

SYSTEM CAPACITIES

S.I. U.S.

Fuel Tank

1

93

L 51 gal.

Hydraulic System: Total (varies

with

options)

65

L (appro

x.

) 17 gal. (approx.)

Reservoir Capacity

54

L 14.4 gal.

Bevel Gear Box 1 L

1 ql.

Power Wheel 1350 mL 45

oz

.

Engine Cooling System:

Diesel

18

L

4.8 gal.

Diesel Engine Crankcase: less Filter 9.5 L 10 qls.

With

Filter 10.4 L

11

qts.

Air Conditioning System:

Refrigerant

(RI34a)

1.36

kg

3lbs

.

Oil (SP-20 PAG) 240

cc·

8.1 fl.oz.·

• - This amount of oil is

the

full

system

req

uirement

and

is

included

in

a new compressor.

Greasing

the

Windrower Tractor

See "Fuels, Fluids and Lubricants

..

for recom-

mended greases.

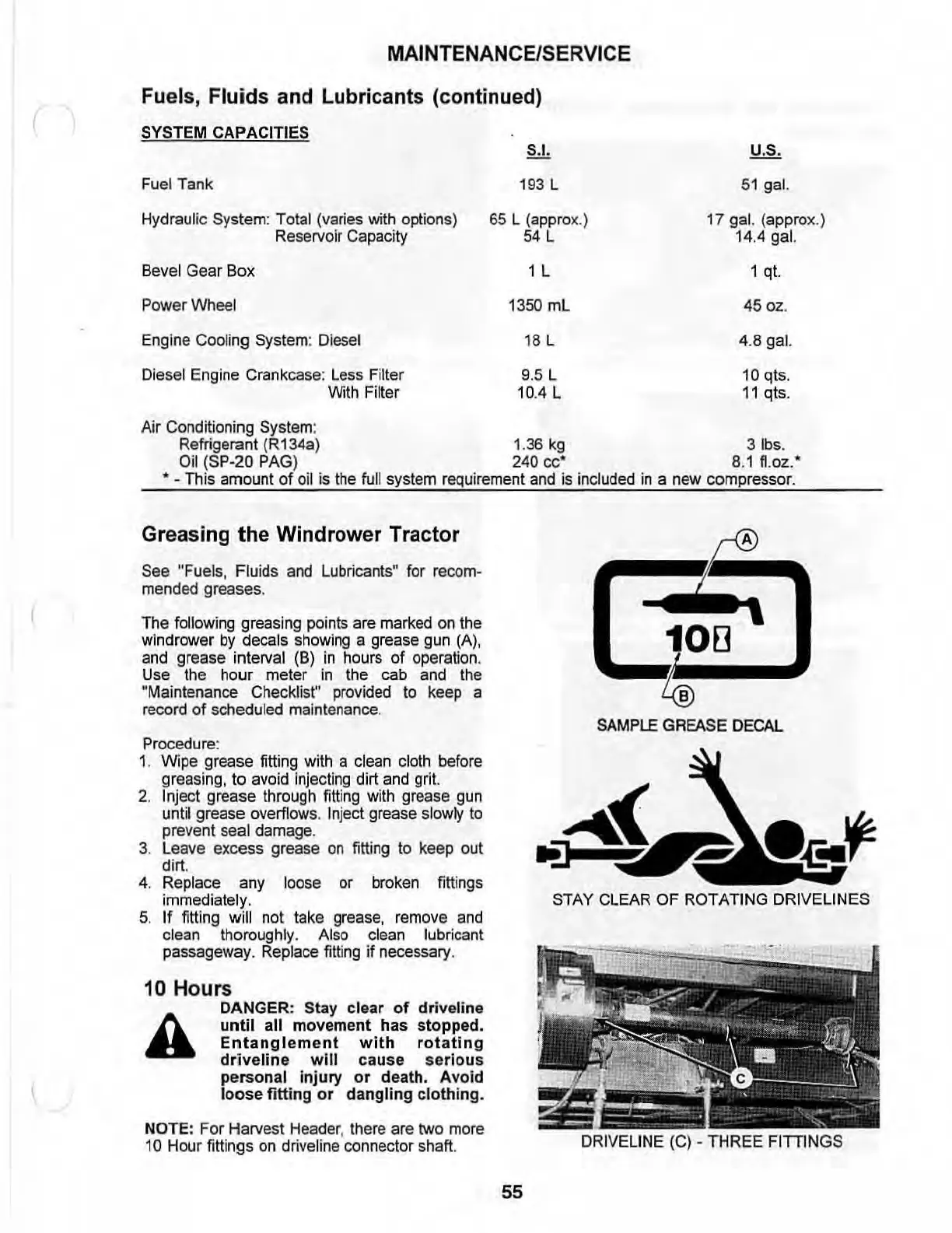

The

following greasing points are

marked

on

the

windrower

by

decals showing a grease

gun

(A)

,

and grease interval (8)

in

hours of operati

on

.

Use

the

hour meter

in

the

cab

a

nd

the

"Maintenance Checklisr'

provided

to

keep a

record of schedu

led

maintenance.

Procedure:

1. Wipe grease fitting with a clean cloth before

greasin

g,

to avoid injecting dirt

and

grit.

2. Inject grease through fitting with grease g

un

until grease overflows.

In

ject grease slowly

to

prevent seal damage.

3.

leave

excess grease

on

fitting to keep out

di

rt

.

4. Replace any loose or broken fittings

immediately.

5.

If

fitting will not take grease, remove

and

clean thoroughly. Also clean lubricant

passageway. Replace fitting if necessary.

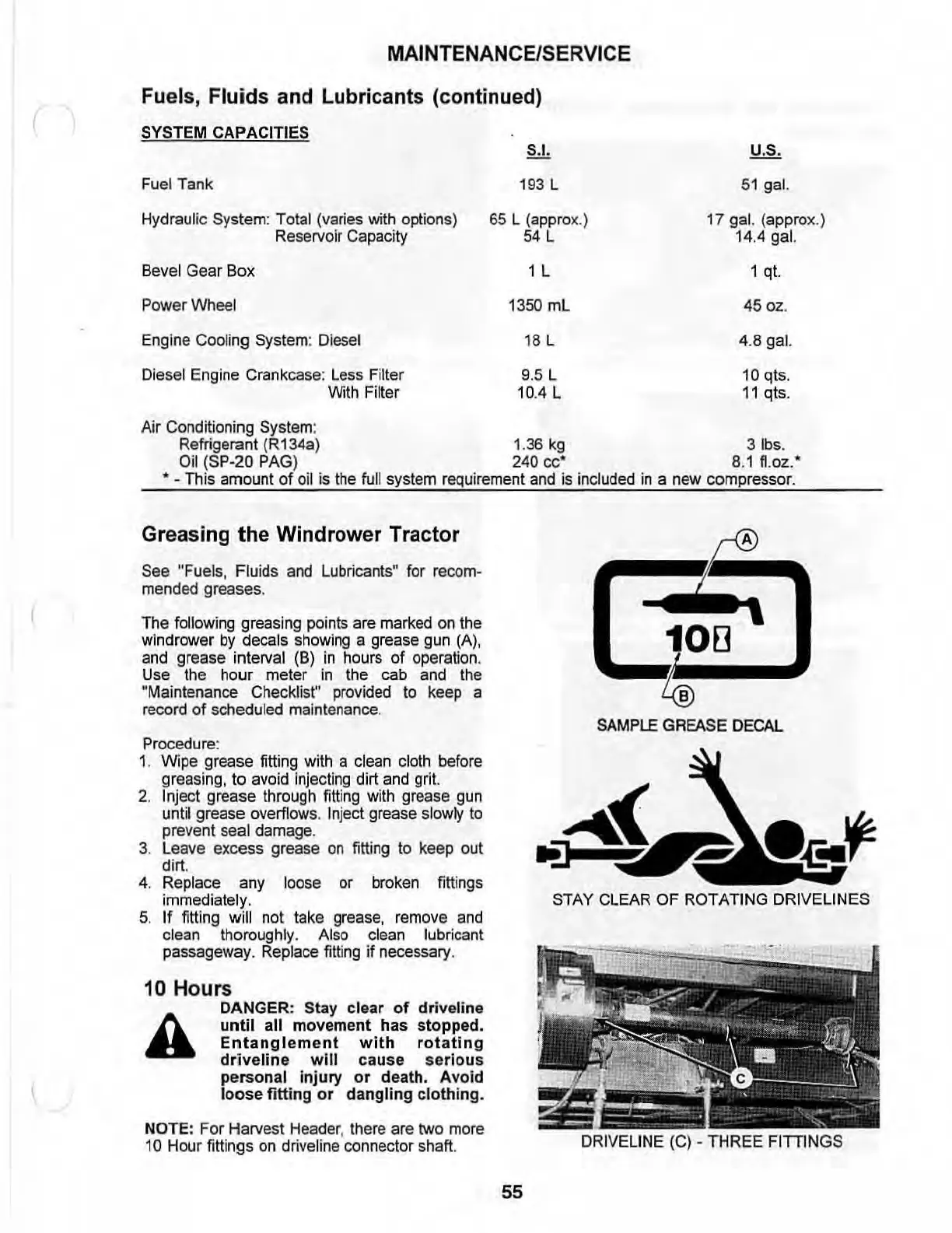

10 Hours

DANGER: Stay clear

of

driveline

until

all

movement

has stopped.

Entanglement

with

rotating

drjveline

will

cause

serious

personal

injury

or

death.

Avo

id

loose

fitting

or

dangling

clothing

.

NOTE: For Harvest Header, there are two mo

re

10

Hour fittings

on

driveline connector shaft.

SAMPLE GREASE DECAL

STAY CLEAR OF ROTATING DRIVELINES

DRIVELINE (C) - THREE FITTIN

GS

55

Loading...

Loading...