169441 153 Revision D

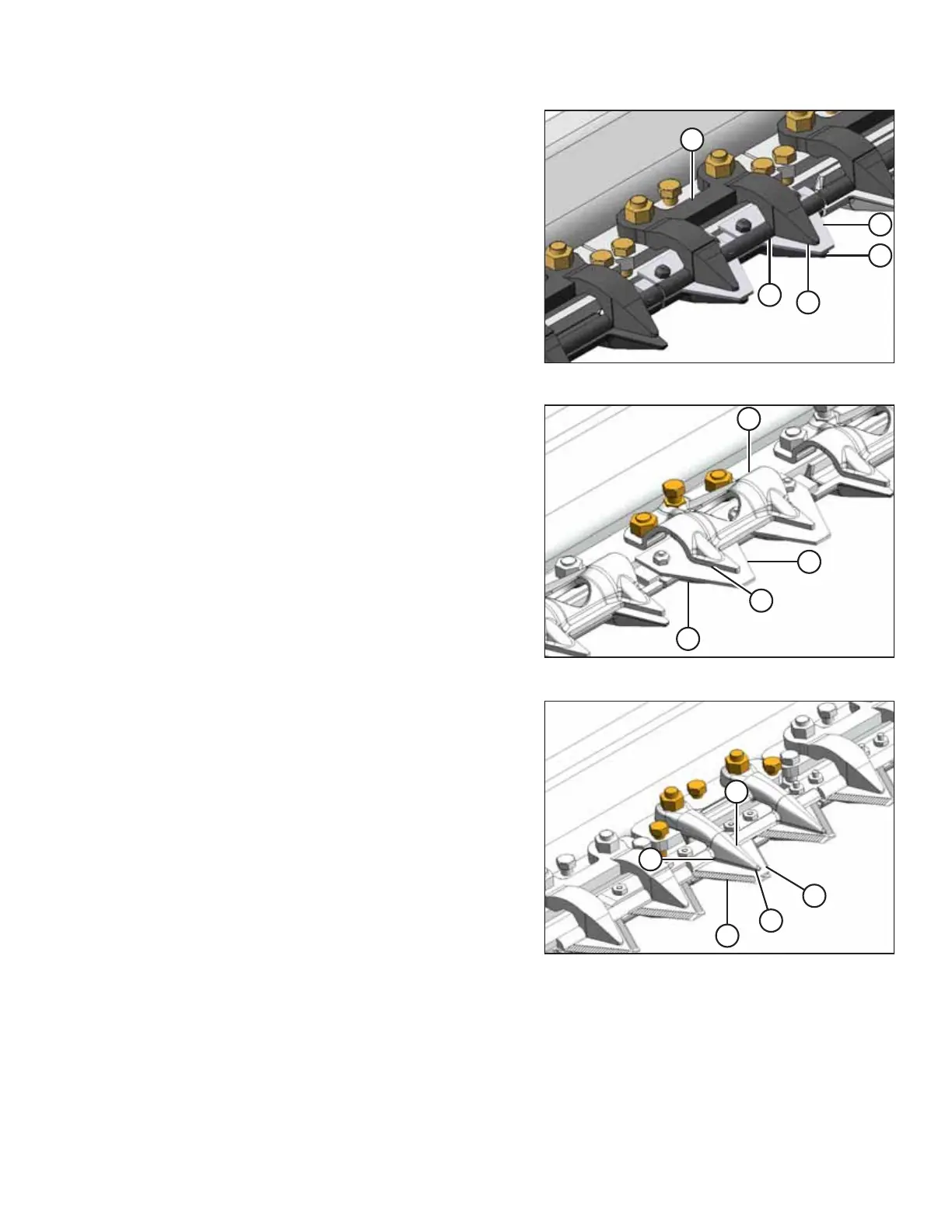

Figure 4.65: Short Knife Forged Hold-Down

Figure 4.66: Short Knife Sheet Metal Hold-Down

2. Manually stroke knife to locate section under

hold-down (A).

3. Standard guard: At standard guard locations, push knife

section (B) down against guard (C) and measure clearance

between hold-down clip (A) and knife section (B) with a

feeler gauge. The clearance should be as follows:

• At hold-down tip (D): 0.1–0.4 mm (0.004–0.016 in.)

• At rear of hold-down (E): 0.1–1.0 mm (0.004–0.040 in.)

• At sheet metal hold-down (F): 0.1–0.6 mm (0.004–

0.024 in.)

4. If necessary, refer to Adjusting Stub Guard Hold-Downs,

page 155.

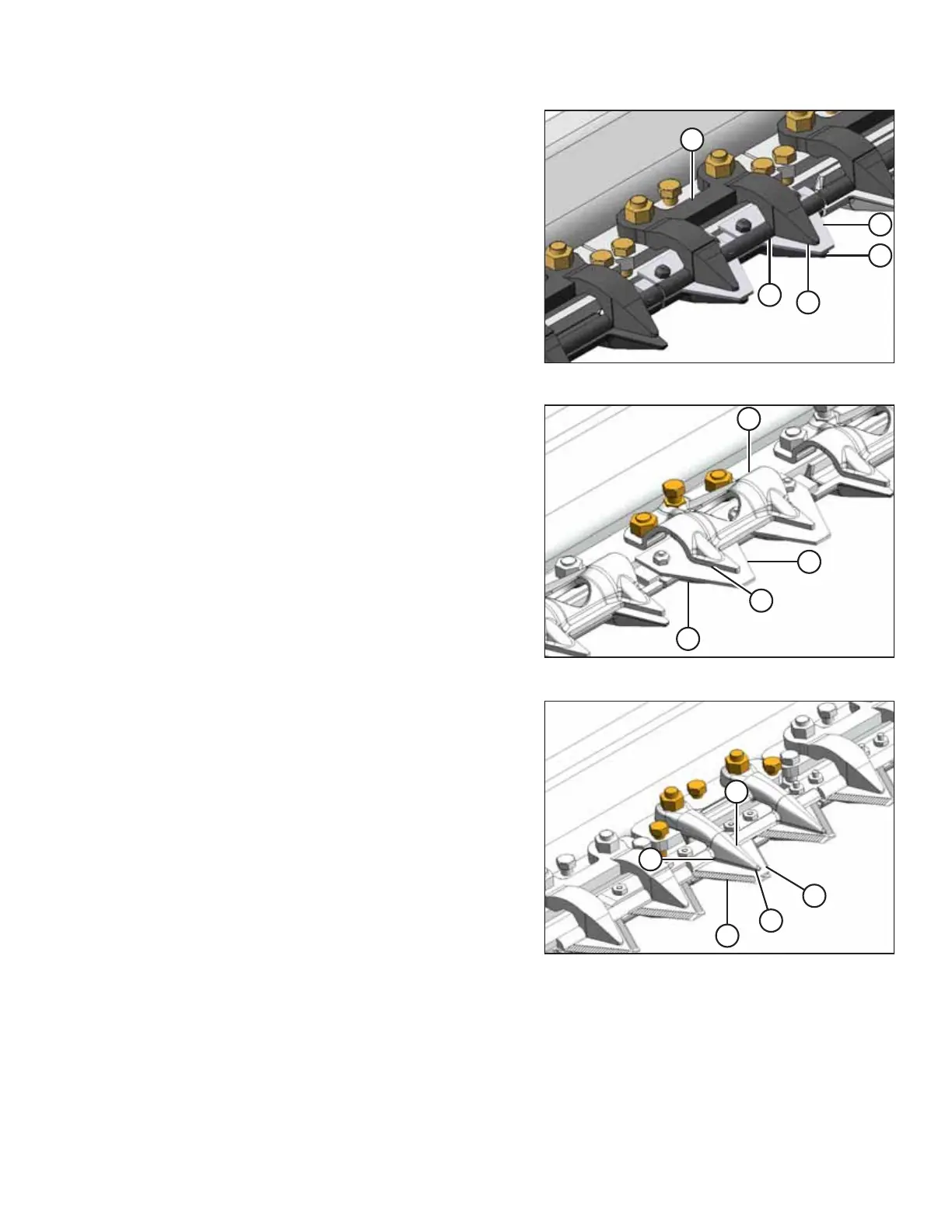

Figure 4.67: Double-Knife Center Short Knife Guard

Hold-Down

5. Double-knife center stub guard: Manually stroke the knife

to locate sections under hold-down (B). Measure clearance

between knife sections (A) and (C) with a feeler gauge. The

clearance should be as follows:

• At hold-down tip (D): 0.1–0.4 mm (0.004–0.016 in.)

• At rear of hold-down (E): 0.1–1.0 mm (0.004–0.040 in.)

6. If necessary, refer to Adjusting Stub Guard Hold-Downs,

page 155.

Adjusting Pointed Guard Hold-Downs

This procedure is applicable to formed sheet metal hold-downs. Do NOT use this procedure for the hold-down at the

center guard position where knives overlap on double-knife headers.

For the center guard, refer to Adjusting Hold-Down Clips at Double-Knife Center Pointed Guard, page 154.

MAINTENANCE AND SERVICING

Loading...

Loading...