169441 244 Revision D

Maintenance

Record Action: üü - Check SS - Lubricate

▲▲ - Change

500 Hours or Annually

S

Reel shaft bearings

S

Stabilizer/slow speed

transport wheel bearings

1000 Hours or 3 Years

▲

Knife drive box lubricant

4.12.4 Checking Hydraulic Hoses and Lines

Check hydraulic hoses and lines daily for signs of leaks.

Figure 4.241: Hydraulic Pressure Hazard

WARNING

• Avoid high-pressure fluids. Escaping fluid can penetrate the

skin causing serious injury.

• Keep your hands and body away from pinholes and nozzles

which can eject fluids under high pressure.

• Relieve pressure before disconnecting hydraulic lines, and

tighten all connections before applying pressure.

• If any fluid is injected into the skin, it must be surgically

removed within a few hours by a doctor familiar with this

type of injury, or gangrene may result.

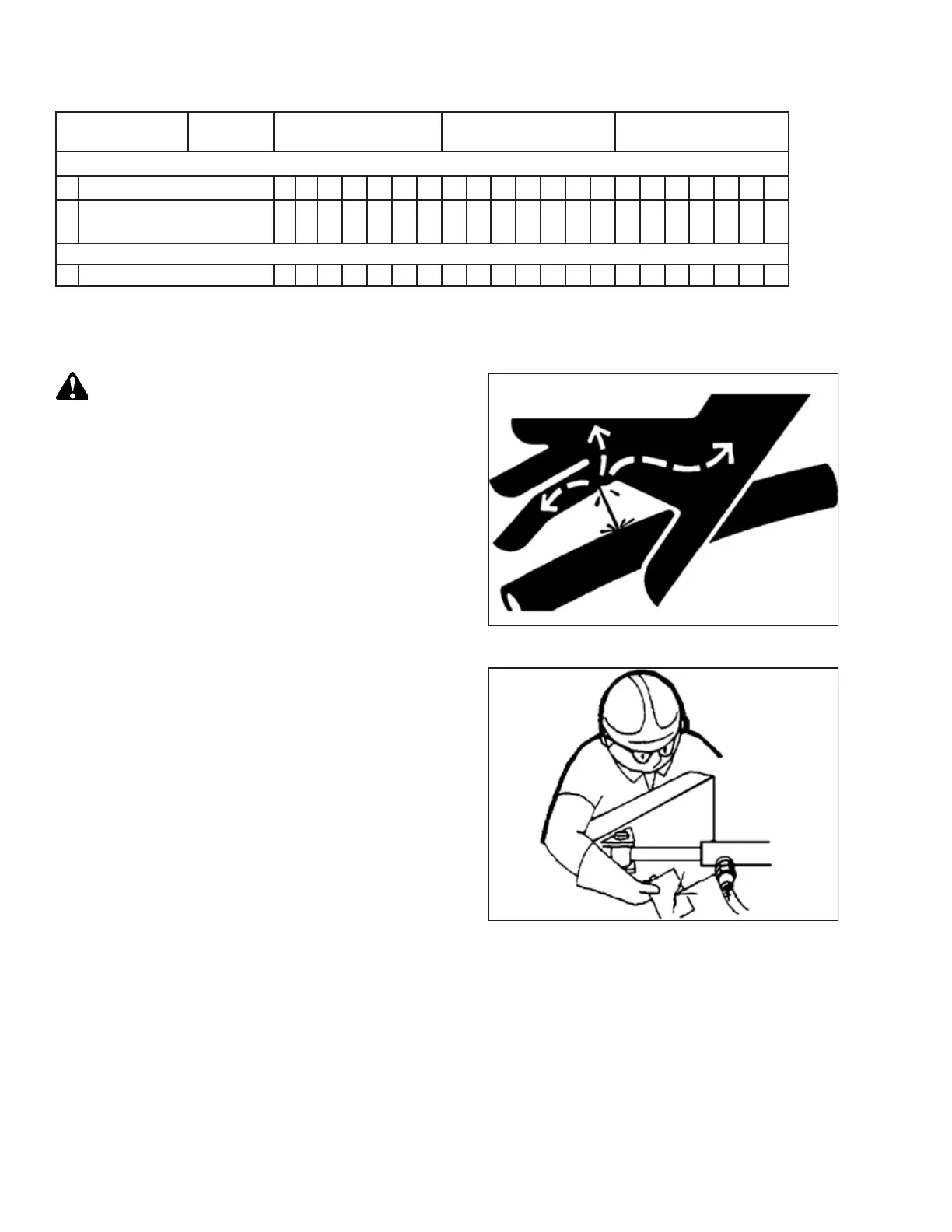

Figure 4.242: Testing for Hydraulic Leaks

• Use a piece of cardboard or paper to search for leaks.

IMPORTANT:

Keep hydraulic coupler tips and connectors clean. The

introduction of dust, dirt, water, or foreign material into a

hydraulic system is the major cause of damage. Do NOT attempt

to service hydraulic systems in the field.

MAINTENANCE AND SERVICING

Loading...

Loading...